Laser sensors possess great importance in instruments where we need to detect the position of objects. It allows machines to work better, and provides us with important information about the world around us. By just changing the position of a robotic laser cutting sensor, you can ensure that it does its job in the most efficient and accurate way possible. So now let us look deeper on laser sensors placement locations and how they could assist us in various conditions

When we put the laser tracker sensor in the proper location, it can function at its most effective, a process known as optimizing efficiency. This will lead us with a precise & accurate information to make an informed decision when laser sensor is good to go! With proper adjustment of the laser beam, we can make sure that the sensor is working at its optimal level and is helping us in our daily life.

Indeed, technology helps us to enrich our laser beam sensor sensors. With the proper tech, we are able to really enhance the precision of that laser sensor positioning. This really means that we can trust what it tells us even more. This, means, that with some technology tools and techniques, we ensure that the laser sensors are oriented accurately as per its requirements.

In production areas or warehouses, laser sensors play an important role in ensuring the seamless and efficient operation of machines. When placing laser sensors in these situations, it is essential to consider a few factors thoroughly. It can be affected by things like the height of the sensor, the angle in which it's placed, and the distance from the objects it is measuring.

There are several advantages of laser sensor positioning presented, especially in the case of measuring and controlling various processes. So by putting this laser sensor in the right position, we can measure things, including the distance, speed, and position, of an object with high precision. This knowledge helps us control machines and allows us to verify their correctness. Providing laser sensor positioning is an innovative system specialized in processes, room and equipment safety.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

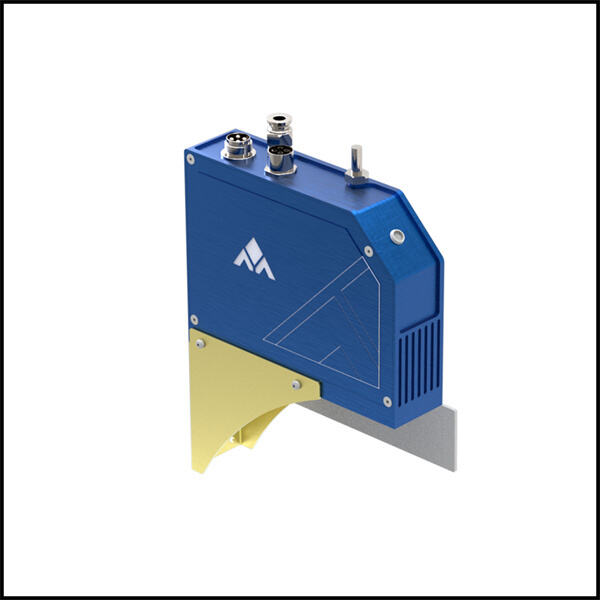

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.