P1: Laser transmitters LIGHT emitted from a laser source are utilized to communicate messages from one place to some other place. You can imagine them as fast messengers that can go long distances without tiring at all. They operate based on a unique type of light that can go directly to its target, thus being incredibly beneficial to various daily activities.

To get an idea of how laser transmitters work, envision a flashlight — but more potent and capable of reaching further. The MINYUE laser transmitter generates the special type of light (laser beam). This is a very narrow beam, meaning that it does not scatter like ordinary light. It focuses there, letting it fly for long distances without becoming weaker. The transmitter contains a special material known as the laser medium. This material is used to generate the laser beam. When this material receives extra energy, it emits tiny light particles called photons. These photons bounce back and forth between two mirrors in the transmitter, which amplifies the little high speed laser sensor further.

Even in some of the most mundane objects that we use, laser transmitters are often at work that we may not even realize! For instance, they appear in barcode scanners at shops. These scanners read the bar codes on products quickly, so that cashiers can ring them up when a customer reaches the register. And, CD and DVD players use laser transmitters. They assist in reading the data stored across the discs, enabling us to relive our favorite movies and tune in to our favorite music. Fiber optic communication systems are another key application. Such systems transmit information at high speeds over long distances using industrial laser sensor that beam the data into very thin glass fibers. This technology makes our connection to the internet possible and enables us to communicate with each other seamlessly.

Laser transmitters are continuously improved upon by scientists and engineers. They keep improving of the strength and direction of the laser beams, so they can transmit data longer distances. Research teams are also working to miniaturize and make laser transmitters more energy-efficient. This potentially allows them to slot into more types of devices we interact with daily. Many of the new generation of laser transmitters use specific mirrors and lenses to focus and direct the industrial laser welding more tightly so it is much more focused and powerful than previous systems.

Use of MINYUE laser transmitters requires a high degree of precision and accuracy. An imprecise laser beam may miss its intended target or diverge, making it less efficient in performing its function. To obtain the best possible measurement, engineers make great efforts to calibrate and test laser transmitters. This is particularly important in medical settings, even where laser light detector are applied in operations and treatment. When that happens, the laser has to strike the precise sweet spot so that it does both for the patient: safely and effectively.

The potential of MINYUE laser transmitters is remarkable in communication and imaging systems. They have the ability to rapidly and precisely convey information over significant distances, making them suitable candidates for wireless communication systems. This implies that we can communicate, whether through text, phone calls, or the internet. Other applications of laser beams include imaging systems, which utilize laser beams to produce detailed and high-resolution images of objects or environments. Laser scanners, for example, can make 3D models of buildings, cars and even human bodies for medical purposes. It could help doctors better learn their patients’ needs.

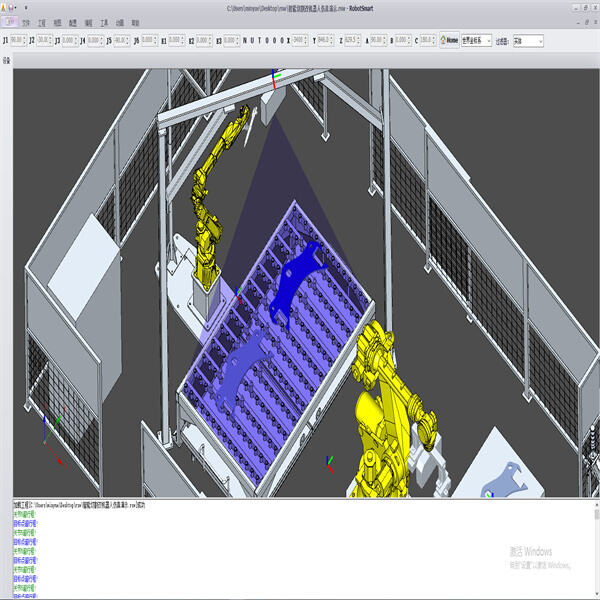

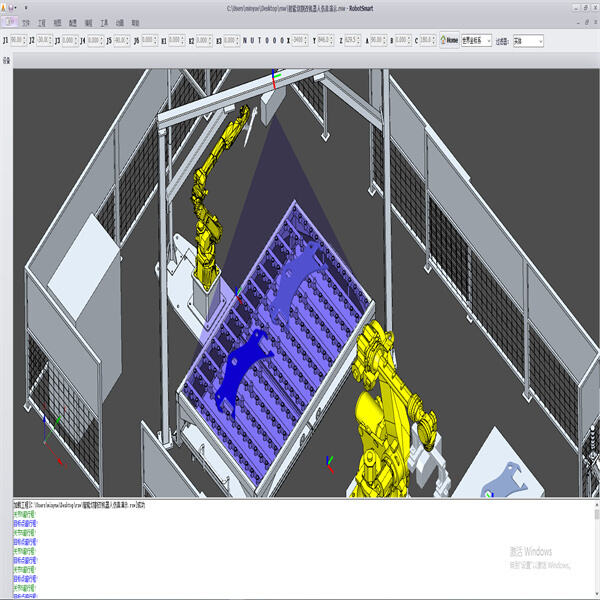

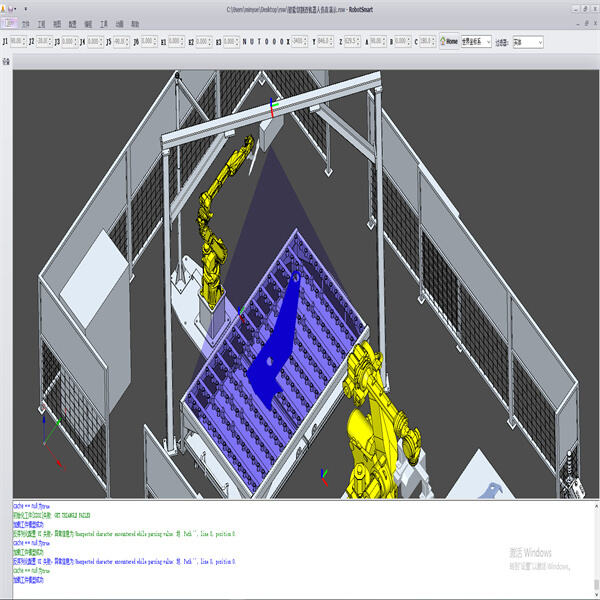

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.