There is absolutely a neat little gizmo known as a laser mild detector. Since you’re reading this sentence, you are on the internet. Join us in this video as we take a closer look at laser light detectors and explore the wonders behind their incredible functions.

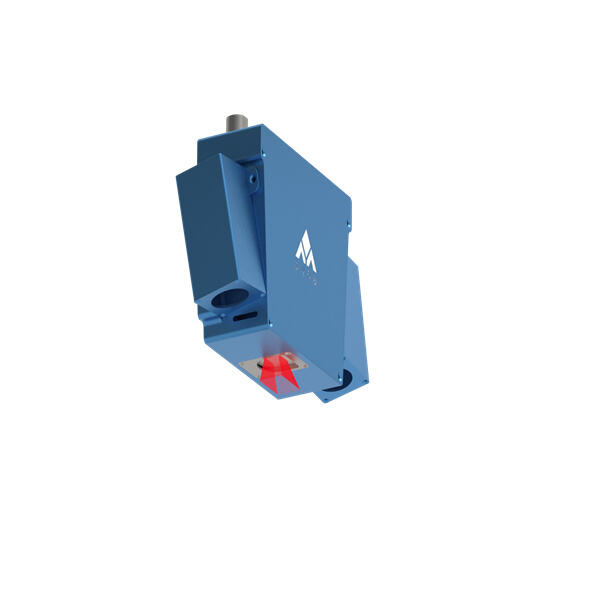

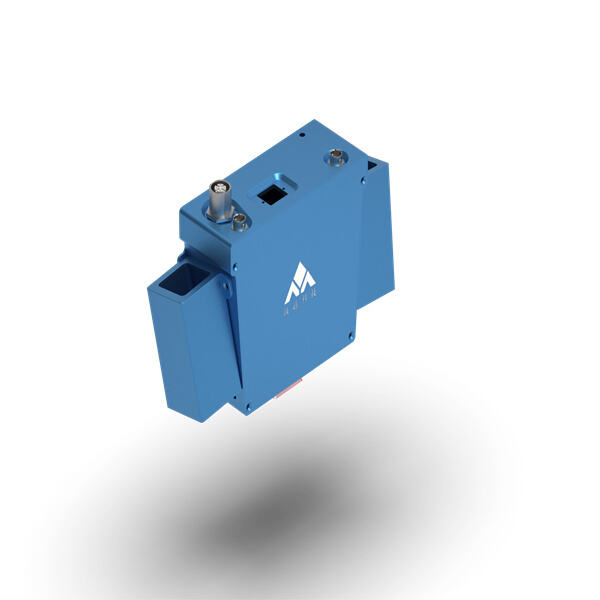

MINYUE Laser light leads to a range of other devices which are able to detect and measure light. They operate with a component known as a photodetector. This component is extremely light-sensitive, making it able to detect even small amounts of light. As light hits the photodetector, it generates an electric signal. Once it absorbs a specific signal, it can be measured and analyzed. This Laser seam tracking system capability allows laser light detectors to detect even low light signals, making them extremely useful in a variety of applications.

MINYUE Laser light detectors have a prominent role in factories and manufacturing. They ensure that the products are developed accurately and quality standards are met. For instance, when a toy factory is working, the detectors of laser lights ensure that every single toy is produced accurately before being released. They may also be utilized to inspect toys and other products to see if they have any issues or defects. In addition, laser light detectors help robots and machines to "see" and navigate safely in their environment. This helps make sure that everything functions correctly in the factory, and that the machines can operate without crashing.

Laser light detectors are very useful tools in keeping people and caring people from places. They can build security systems that can detect when someone accesses a secure area without authorization. That matters in places like banks, museums or even private residences. MINYUE Laser light detectors are used in motion sensors as well. These sensors can notify security personnel if there is some unusual or suspicious activity going on. Perhaps the most solid feature of Smart welding solutions is how accurate and of great reliability they are. The reliability helps to protect people and property through the functionality of security systems.

Calibration: Laser light detectors must be calibrated regularly in order to function properly and accurately. Calibration: the process of adjusting the detector to a known standard in order to measure accurately. Right like how you need to set the time on a clock so that way it tells you the correct time, laser light detectors also processes need to be calibrated to provide a correct reading. This is important, as it keeps the detector functioning properly and helps it get more reliable with time. If the detector is not calibrated correctly, it may result in an inaccurate measurement, which can lead to errors in your overall results and interpretation of the data.

Laser Light Detectors The various applications of laser light detectors in the field of research have been fascinating. Scientists incorporate them in experiments, measuring and studying light signals. One example is when researchers want to study how light interacts with a range of materials — they apply a light detector to the laser light. They are useful in medical research, as well; physicians and scientists study them to analyze how tissues and cells behave and what their properties are to learn how tissues and cells function. Moreover, robot laser welding machine find applications in environmental monitoring. Measuring how much light is absorbed or reflected by various substances in the environment helps track how much pollution is there, helps study climate change. Researchers and scientists use laser-light detectors as versatile, accurate instruments in virtually every scientific discipline.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.