Seam tracking is an invaluable component of welding. One Process Guide is used to ensure that the weld is performed correctly, which is important for the final product's strength and safety. Working with different types and sizes of materials, it is hard for people to keep the weld in the correct position when they are welding. Seam tracking technology is where this all really falls into place. It keeps the weld in place throughout the whole welding process. This MINYUE Laser seam tracking system is extremely useful as it guarantees that the components are actually properly and securely welded together.

It is very important that when people are welding, they keep the weld in a specific position. "Poor placement of the weld could cause the two components to separate or the assembly to fail. This is where seam tracking becomes useful. Why is this technology needed? Seam tracking technology assists welders to make sure the weld stays in the right position. It is designed to see if the weld begins to drift from where it is supposed to be and can adjust with rapidity. Thus the welding is completed, and the resultant item is powerful. The welders can be assured that their welding would be strong and safe for usage with the seam tracking systems of MINYUE.

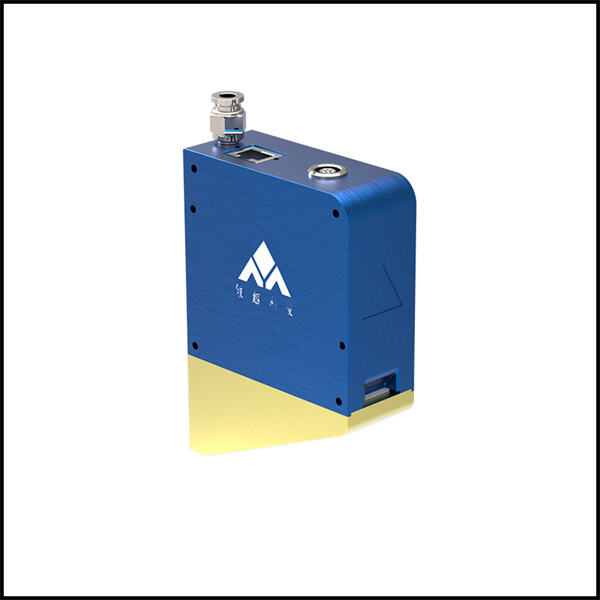

Various aspects of the welding process can be improved through the use of this seam tracking technology. Its main thing is, it can see if the weld is not in the right place, make a correction. This ensures that the weld is strong and secure, lowering the possibility of any future issues. MINYUE's seam tracking systems employ sensors that track the weld in real time. This real-time tracking ensures that the weld remains in the correct position at all times. By utilizing MINYUE seam detector sensor, the welding accuracy is optimized and thus, stronger and longer-lasting products are produced.

Seam tracking systems have been used in various industrial factories and have several advantages. One of the biggest advantages is that MINYUE laser seam tracking sensor improves welding accuracy, thus ensuring that the products are now made stronger and are safer to be used. Proper welding reduces the risk of errors that could result in product failure. The seam tracking technology can also result in significant time saving in production process. This enables more items to be produced in less time provided welders have this technology at their disposal. MINYUE designs and produces state-of-the-art seam tracking systems that will benefit brands in upgrading the welding processes of their products and create better ones.

Seam tracking technology has the potential to greatly increase the quality and speed accounts for welding jobs. When the weld is held in the correct position, it avoids wasting time having to make amendments or repairs. This type of efficiency also means that you can make more products in less time, which is beneficial to businesses. MINYUE seam tracking sensor are designed to increase efficiency and productivity in welding processes. Seam tracking technology enable organizations to increase their productivity and completes the deadlines with ease, necessary in today’s rapid-paced manufacturing sector.

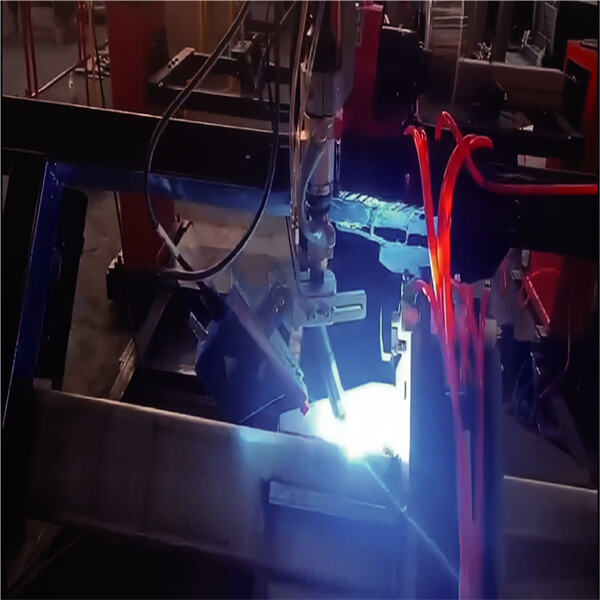

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.