Have you heard about the photoelectric laser sensors? Well, they are mean machines that allow you to see things that are invisible to your eyes. These light-based objects detectors are really valuable in various applications. Similar to superheroes for machines! So, let’s take a closer look at these amazing MINYUE binocular structured light vision sensors and how they function.

Photoelectric laser sensors are unique devices that detect objects based on a laser beam. They function by firing a beam of light, then measuring the time it takes for the light to bounce back after striking something. This is similar to how we can echo in a shout in a large empty space. The sensor takes this time to determine whether or not an object is in front of the sensor. Isn't that neat? This feature enables machines to make decisions based on what they can "see" with laser light.

If an object comes between the object and the laser beam, they will reflect that light back to the sensor. Think of it as shining a flashlight on a shiny surface and suddenly seeing the light bounce back at you. The sensor takes this information and uses it to determine whether the object is there, how far away it is and sometimes even what shape it is. This is important, as it enables the sensor to transmit information to other machines or computers. Using these sensors they detect what is going on around themselves in order to respond rapidly and correctly.

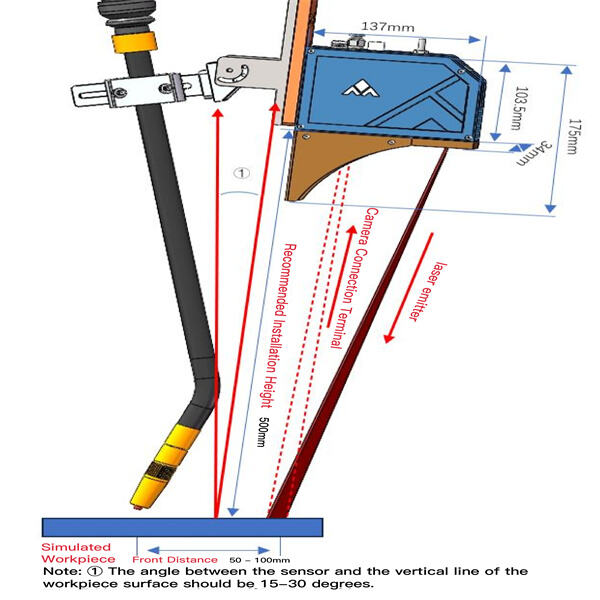

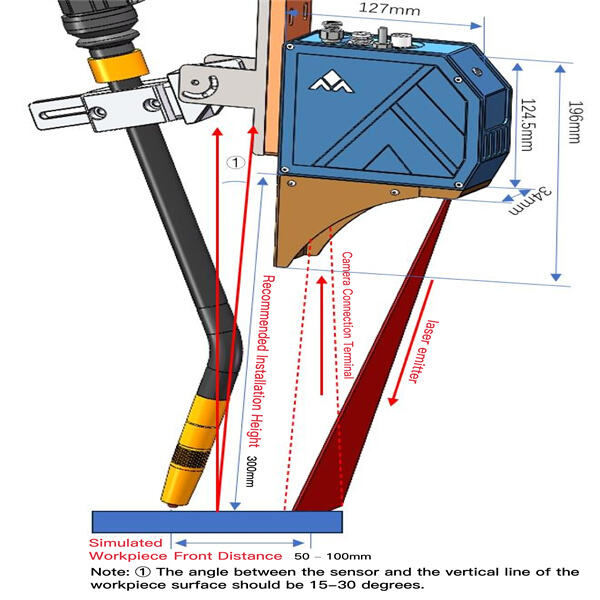

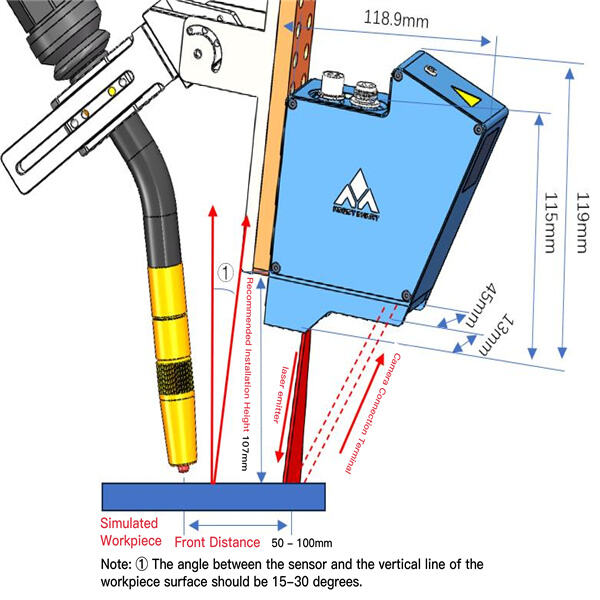

Many people are not aware that photoelectric laser sensors are used almost everywhere, especially in factories and where machines work together. MINYUE different types of sensors in robotics help machines and robots “see” what’s around them, as we do with our eyes. For instance, these sensors can determine whether a product is properly aligned as it moves along a conveyor belt (a mobile path that transports products). They can measure sizes or test quality of products. This allows companies to ensure that the entire mechanism works efficiently.

Photoelectric laser sensors are one of the most accurate systems available. These sensors can locate objects with great accuracy which is a critical need in factories where errors can lead to huge loss of money. If you think of a factory that produces toys. An incorrectly put together toy can be hazardous for children. Which is why these sensors can be so useful! MINYUE laser beam sensor are used in TONS of ways, from checking packages to making sure machines operate properly. They are also straightforward to configure and maintain, making them an ideal choice for businesses looking to enhance their operations and protect their assets.

Like most devices, photoelectric laser sensors can have issues also. One common problem is interference from other light sources, such as sunlight or bright lights. This may confuse the sensor and lead it to provide accurate readings, which is bad. To remedy this, the MINYUE laser proximity sensor must be shielded from these other lights. The other issue can be caused when the lens of the sensor gets covered by dirt or dust, which makes it difficult for the laser light to function correctly. Just like we need to clean our glasses to see properly, we need to keep the sensor clear to avoid such problems.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.