An IR laser sensor is a very cool and simple piece of technology that enhances machine and gadget functions. Hopefully you have never heard of an IR laser sensor? It fits like a very small eye, allowing it to observe what is otherwise out of our field of vision. So, today we will know a lot more about the working of IR laser based sensors and their uses in our daily life.

Infrared laser sniper sensor A infrared sniper laser sniper sniper sniper sniper is a sniper that uses the principle of grazing to detect objects. One type of light that our own eyes are unable to see is infrared light, which an IR laser sensor can detect very well. These sensors emits a beam of infrared light, when this light hits an object it bounces back to the sensor. The sensor then uses that information to determine the distance of the object and its shape. This is extremely helpful because it allows machines and gadgets to know where things are as well as how they can go around things without hitting into anything. On that note, if you want to prevent a crashing desktop room full of furniture or similar, robotic laser cutting sensors go a long way in helping your devices navigate around obstacles safely.

IR laser sensors are important, as they make a lot of things perform accurately and efficiently. As an example, consider a robot in a warehouse that picks up objects. An laser welding robot system lets that robot know precisely where each item is. This allows the robot to pick the items without errors and dropping anything. This idea and sensors are also used in security systems to alert movement. They ensure that people aren’t trying to break into a building. These sensors act as little safety detectives, looking out for anything suspicious. They keep everything moving along smoothly and make our lives easier.

Now, let’s get into calibration. Calibration is a fancy term for ensuring that a sensor is functioning correctly and accurately. MINYUE IR laser sensors need much more calibration than any standard sensor. That only has to be verified and adjusted so that they emit and capture the right amount of infrared light. Calibration is similar to tuning a musical instrument. Similar to how a guitar requires tuning to sound nice, distance measuring sensors require fine-tuning to operate at peak performance. When sensors are appropriately calibrated, they provide the best information possible.

Like so many areas of tech, IR laser sensor technology has evolved and improved over time. To reduce, speed up and enhance IR laser detectors, scientists and engineers are tirelessly laboring. This means these sensors can be used in many new ways and in far more places than before. IR laser sensors are now being introduced into self-driving cars and allowing them to safely navigate on the road. Like for example, they help the cars sense barriers and/or make secure decisions for driving. IR laser sensors also appear in smartphones, as part of facial recognition and augmented reality. So when you unlock your phone with your face, or play with nice filters, laser sensor for distance measurement are mostly doing all the work to make that work for you. Such sensors have unlimited applications, and they are becoming increasingly significant in our daily lives.

IR laser sensors have a wide range of applications in industrial and consumer electronics. IR laser sensors are being used in factories and industrial applications to track production lines, detecting faults in the product, and ensuring employee safety. So, they enable the workplace to be safe and efficient. Consumer electronic devices (smart TVs, gaming consoles, virtual reality headsets) use IR laser sensors. They refine the functionalities of these devices and upgrade the user experience to make them easy and enjoyable to use. That demonstrates that IR laser sensors are really significant and vital elements in our everyday routine and contemporary innovation.

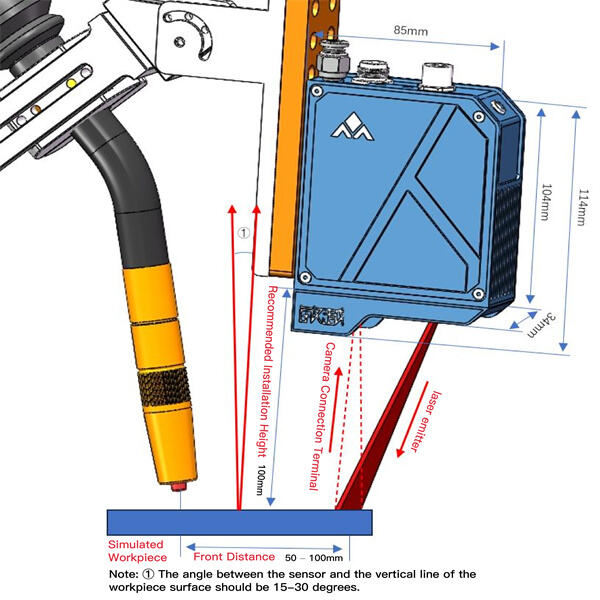

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.