The laser range sensor is a very cool tool that allows us to measure distance without physical contact. It’s sort of like having this special helper that tells us how far that thing is from us. It is not very much different than trying to guess how far away your friend is without standing up. This automated welding robot tool does just that! Now let’s explore how it works and why it’s so important in the world we live in

Laser range sensors can detect the distance to an object by determining how long it takes a laser beam to bounce off that object and back. It’s a little like directing a flashlight in a dark room and seeing how far the light reaches. These sensors use lasers instead of regular light, lasers are super precise and can measure distances really effectively. The sensor shoots a laser beam and listens to see how long it takes for the beam to bounce back after hitting something. By timing how long it takes for the beam to bounce back, the sensor can determine exactly how far away the object is. This was how it assists us in measuring distances without needing to be on the same position!

Laser range sensors form an integral part of various applications in technology as they enable machines to “see” their surroundings. More recently, they have been involved in everything from robots to drones to self-driving cars! As an example, consider a robot that is trying to navigate around a room. If it automated welding equipment didn’t know what distance a wall was, it might bump right into it, and that’s a problem! But with a laser range sensor, the robot measures the distance to the wall and avoids crashing into it. This does a lot of good, keeping things secure, and making sure machines run well.

There are so many cool things laser range sensors can do! They robotic aluminum welding contribute to creating maps by measuring distances between different points, they accurately measure distances in many situations, they can even find objects in the dark. To give you one example, if you play hide-and-seek in a completely dark room, a laser range sensor can help you to find your hiding friends! It’s like having a power that can see further, daggers will envy! They’re also used in medical machines to gauge things, such as the gap between your eyes when you get an eye exam. Laser range sensors make things easier and more effective, so they are essential in our daily lives.

Laser range sensors come in another flavor, and are not as simple. Other sensors have one beam of laser while many have multiple beams that help to take a more extensive and precise measurement. Some sensors are tuned specifically to accurately measure short distances while others are better suited for longer distance measurements. It’s similar to having an assortment of tools in a toolbox — each one is made for a different purpose. It robot laser welding machine helps us to use the appropriate type of laser range sensor for the work to ensure an accurate and precise measurement to achieve successful results.

It's a really exciting future for laser range sensor technology! And scientists and engineers are constantly working to improve these sensors — to make them more affordable, efficient, accurate, and flexible. Making them smaller so they can be fit into more devices, faster so they can deliver the information we need more quickly, and even more accurate so we can count on the measurements they give us. It can indeed help transport, health care, and electronics etc. Perhaps one day, laser range sensors will become so advanced they automatic welding robot can even help us with homework or play games with us! The potential of what these sensors could do in the future are endless and extremely exciting.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

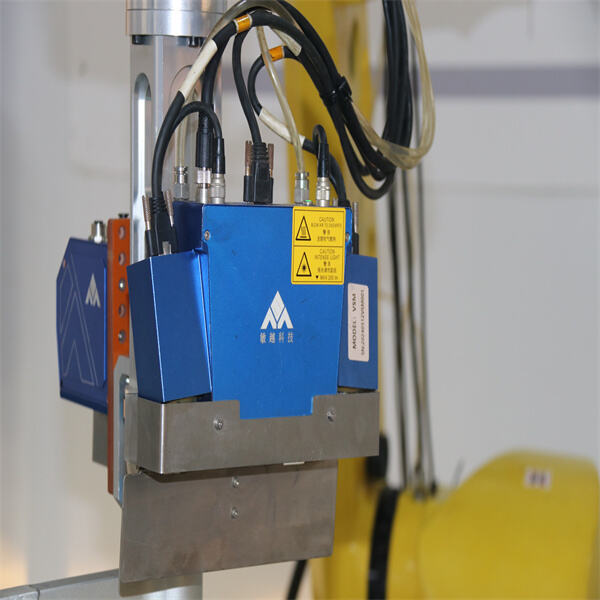

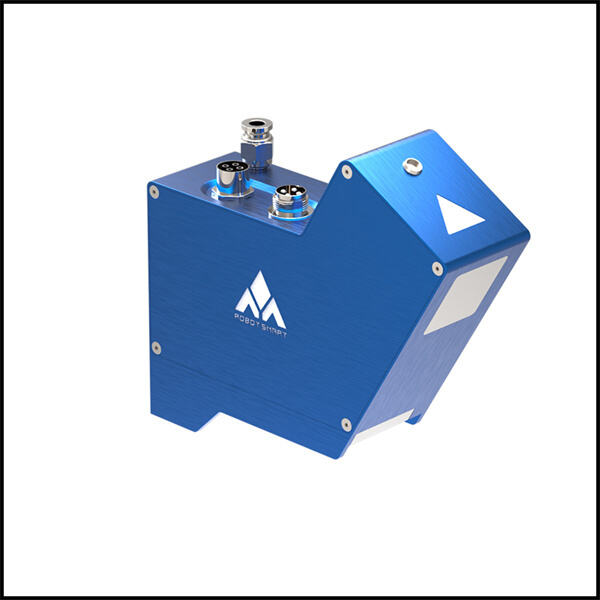

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.