Robot offline programming really is a cool new way to teach robots smarter moves! Using this technology, MINYUE’s robots can perform their duties without requiring an internet connection to learn how. This is really useful as it lets them complete their work a lot quicker and more productively. So, how can MINYUE robot handling system improve manufacturing and factory work?

Robot offline programming has benefited companies in saving a whole lot of time and resources. Typically, engineers must train each robot, one by one, to do its job, which is tedious and time-consuming. With offline programming, on the other hand, engineers can program the robots using specialized software, completely independent from an internet connection. That means they can experiment with moves and strategies on the computer before getting to the point where they have to give directions to the robots. They can do all this without even having to touch the robots in a factory. That allows the robots to start working much faster, since they do not need to remain tethered to a computer all of the time.

Instead, companies can cross tons of hours on robot offline programming. Because you can program robots offline, engineers can spend less time teaching them to do their jobs. That way, they will not have to waste time on tedious tasks such as improving the manufacturing process or even creating new products that people will enjoy. Another nice thing is that businesses can cut costs on training and repairing the robots, as they do not have to continuously update them with fresh information. This makes companies resource-efficient and contributes to the development of the companies.

If you are looking to leverage robot offline programming in your work then you may want to consider the following key factors. You'd first need software and tools that program the robots offline. With MINYUE robotic welding systems, you can access a range of software solutions to help kick start your robot offline programming journey. You must select the right software that works for you to achieve the best results. You will additionally have to train your engineers on how to operate the software and program the robots accurately. It is important to undergo this training so that everyone knows how to interact with the robots correctly. Once it's all sorted, with your team trained, you will be reaping the rewards of robot offline programming in no time!

Robot offline programming make manufacturing future very bright. With a plethora of data, used to make better decisions by robotics and machines, robots are going to become more intelligent and efficient as technology progresses. That would allow companies to make products much faster and better quality. Endless possibilities with MINYUE's robots! MINYUE automated robotic welding systems can do things too dangerous or tedious for humans to do. Through this collaboration, workplaces can be better and safer. That’s the thrilling promise of offline robot programming, the manufacturing of the future.

Implementing robot offline programming in your workflow can significantly enhance the efficiency of your manufacturing process. MINYUE Welding intelligent decision system perform work faster and with greater accuracy than any human. You would be able to manufacture more products in a shorter time, which is essential for adjusting to customer requirements. So the faster you can make Products, the better your Business grows! By using offline programming, robots do not require to be used immediately, thus, reducing error and enhancing safety. Elevation in manufacturing is what MINYUE brings to you, with its robots accompanying you to provide excellent results!

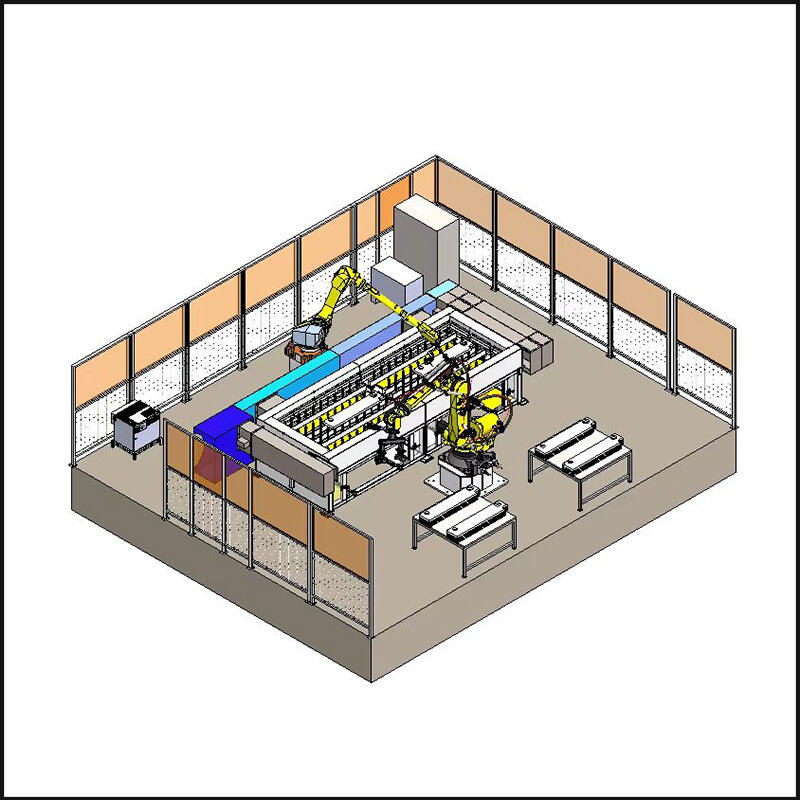

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

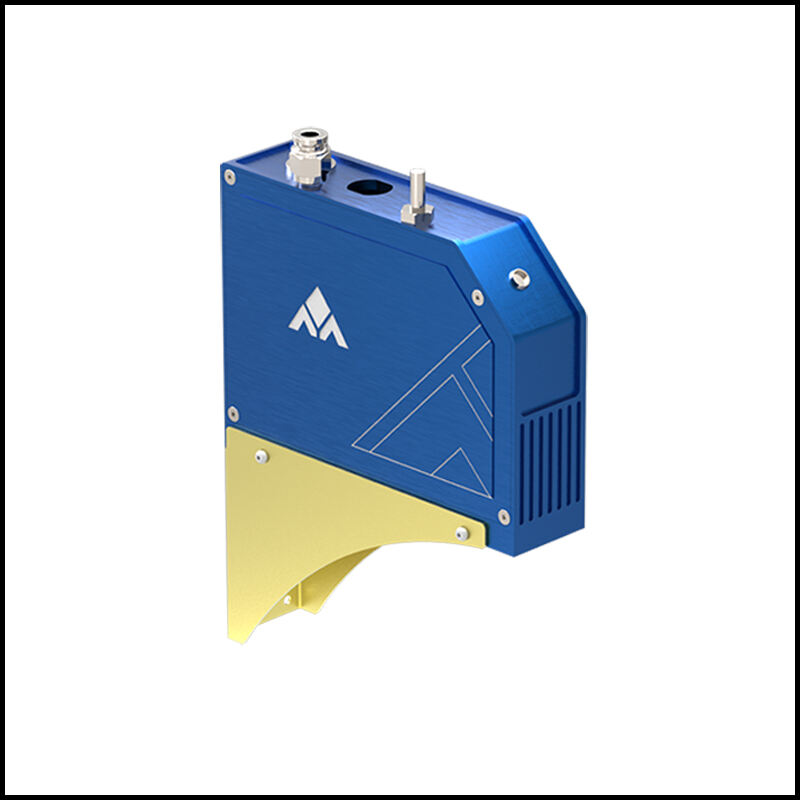

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.