PAST: I Wonder How Welding Will Evolve in the Future? Well, today, be ready to explore the fascinating industry of welding technology, with a little help from a company known as MINYUE!

Welding is an age-old process that has been actively used for quite some time. We need to make lots of great things, like cars that can drive on the road, long buildings where people can live and work, and colorful playgrounds where all the kids catch fun. And as technology improves, the way weld is also advancing. With the release of new tools and MINYUE intelligent robotics systems technologies, welding will become even more refined and accelerated in the future.

MINYUE is revolutionizing the welding industry in exciting ways and one of them is by harnessing data. But what is data? Data is information we gather and use to make decisions. MINYUE robotic welding systems absorbs critical data on the materials up for welding, the temperature of welding tools, and even the weather outside. This data allows MINYUE to ensure that every weld is strong and perfect, every time. Proper welding means final products are tougher and last longer, which is a win-win for everybody!

Artificial intelligence, or AI, is a kind of advanced technology that enables computers to learn and think somewhat like us humans. This means that we can make computers help us with problems and decisions. MINYUE: AI Making Welding Smarter- They feed the computer key information about every project, such as what type of metal will be used and how strong the weld must be. With this information, the AI is able to determine the most effective way to weld the pieces. The process is also much more accurate, which saves time and money for those companies that conduct welding work.

MINYUE also make intelligent welding automation equipment, which is fantastic. Such every one of these systems help welders make sound decisions for their assignments. MINYUE employs data and artificial intelligence to recommend suitable welding approaches for each particular task. MINYUE laser welding robot system is super useful because it enables welders to worry less about how to perform the welding and more on the actual welding! Since less errors occur during the process of welding, the end products are a lot more secure though, and reliable for everyone.

Welding jobs have never been more smooth and good with MINYUE's technology. MINYUE automated robotic welding systems monitor the performance of the welding tools and verify data in real time. Even if there are some problems, MINYUE can identify them in time and solve them before they become larger issues. Quick responses allow projects to be completed faster and to a much higher standard. If customers are happy, it means that the businesses are doing great!

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

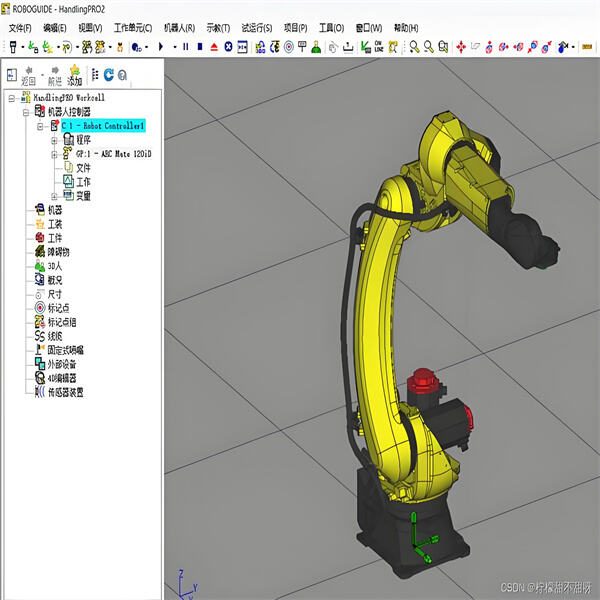

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

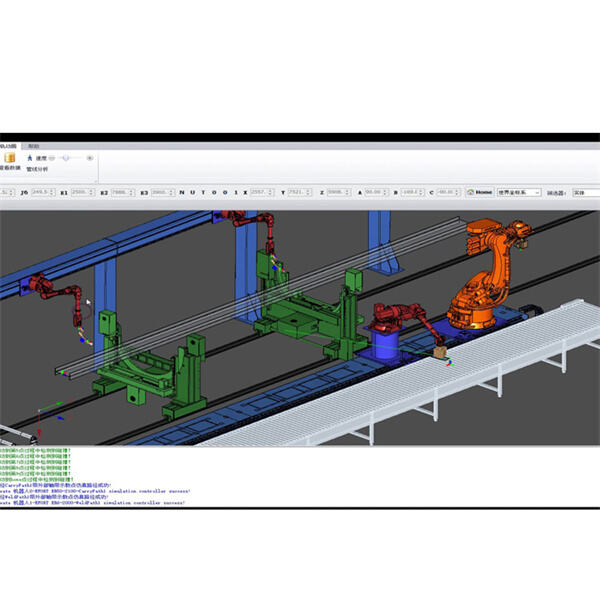

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.