Laser power sensors are devices that are used to measure the intensity of a light source. These sensors are extremely crucial in various fields of science and technology. This lesson introduces the concept of laser power sensors, how they work, and their benefits.

Laser power sensors—devices that let us know how much energy is contained in a laser beam. They do their magic by using special materials that change when they are hit with light. Specifically when the laser light strikes these materials they respond. We were able to measure this reaction and gauge how intense the laser was using this sensor. MINYUE laser beam sensor is extremely useful because it means scientists and engineers know precisely how much energy the laser is generating.

Many applications use laser power sensors to measure how strong a light is. For instance, scientists frequently use them to verify laser intensities while performing measurements. These things can be really important for science in discovering new things. Engineers also use laser power sensors to ensure that lasers in machines are operating correctly. At least they know how powerful the laser is so they can make sure that it is all working (or not working) as intended. This is important because using a laser that is too weak or too strong can create issues in both experiments and mechanical equipment.

When dealing with laser power sensors, calibration is a critical step. Calibration: This involves ensuring that the how the sensor is functioning and reads accurately. A sensor that is not properly calibrated can provide inaccurate data, leading to errors. Special tools are used by scientists and engineers to fine-tune the sensor to ensure it is operating at optimum levels. In the absence of calibration, the sensor will not operate accurately and can introduce severe errors in the experiments or machines. This is why calibration is one of the most important aspects of working with a MINYUE laser sensor for distance measurement.

It is important, when choosing a laser power sensor, to really think about how you will use them. Some sensors suit some types of lasers and situations better than other sensors. Some sensors, for example, measure very high-powered lasers that put out a lot of energy, while others are low-power and measure less energy. Just select the most appropriate MINYUE laser proximity sensor for your application in order to obtain the most accurate readings possible. Depending on which sensor you choose, it may not provide you with the information that you require.

Technology is always improving, and the same can be said for laser power sensors. To improve the performance of these sensors, scientists and engineers are working constantly so that these sensors can be accurate and reliable. They are generating novel materials and designs that make the sensors smaller, more sensitive and more effective to use. These MINYUE Laser seam tracking system are super exciting because they allow research and engineering to happen much faster and much better. Having better sensors allows scientists to discover more and helps engineers build machines more confidently.

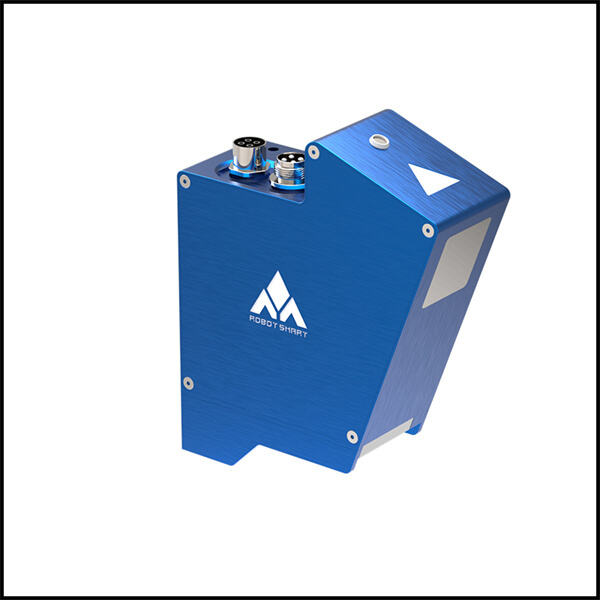

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.