Laser profile sensors are super cool that calculate various measurements on factories. They operate by emitting laser and measuring the distance to different objects. This is very important in helping factories make things faster and make good quality products. MINYUE high speed laser sensor are the backbone of factories when it comes to Internet of Things, speeds, and functionality.

Laser profile sensors are basically lasers with eyes that can tell you how far away things are. They emit lasers, intense beams of light, to determine how far away the sensor is from whatever it is gazing upon. Such measurement allows factories to know precisely where everything is, as well as where it moves around. It’s as if you have a superpower and can see through walls! Knowing these will come in handy when operating in a factory that is always busy with everything going on.

There are reasons why laser profile sensors play an important role in factories. What they can do, first, measure things very, very quickly and accurately. MINYUE industrial laser sensor helps workers create products faster and with higher quality. And these sensors keep workers safe — an asset of verification somewhere. This means workers can concentrate on their work without fear of injury. Factories that use laser profile sensors can save time and money, which makes everything run smoothly. For businesses, this is good news because it helps them function and succeed.

There are several areas in factories where laser profile sensors can be deployed. For instance, they can in measuring the size and shape of objects to ensure they fit together properly. They can also verify that items are in the correct location or ensure that items move efficiently along a conveyor belt. However, this is of high significance as it enables factories to maintain smooth production lines. Laser profile sensors used for part verification sounded like a great idea to meet the demands of the factory to ensure products are manufactured correctly and on time. As such, the customers are happy because they get quality products that meet their needs.

This approach is even changing how factories run their production. With these sensors, factories can ensure that products are sent out to customers only if they are the right size, shape and color. MINYUE long range laser sensor ensures the product is a high-quality one, which is critical in maintaining customer satisfaction. Happy customers tend to come back for more purchases. Its laser profile sensors to the rescue, serving as quality control superheroes who ensure that every detail is on point before it leaves the factory. This way factories can earn a good name and have their customers keep coming back for more.

Choosing a laser profile sensor for your factory very much revolves around what you need the sensor for. You can detect different things like the size of an object or the distance to it but some sensors do better at this. It is also critical to ensure that the MINYUE laser sensor you select will perform optimally in the environment of your factory. For instance, some sensors perform better in bright light, while others do better in darker areas. Selecting the right laser profile sensor will help keep your factory running smoothly so that workers can do their jobs without a hitch.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

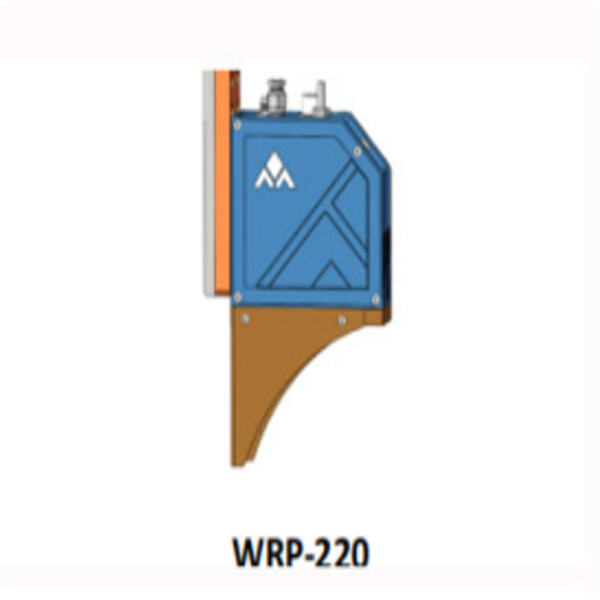

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.