Welding with a Kuka Robot & seam tracking sensor can improve welds. Seam Tracking Sensor - MINYUE Fanuc Robot seam tracking sensor is used for tracing the line along which the metal pieces are joining. This ensures that every weld undergoes meticulous execution. This matters a lot at places like car and airplane factories, where strong welds help keep everything safe and running well.

A key element of a Kuka Robot for producing robust products using its proprietary seam tracking sensor. The robot can detect changes in the weld line and adapt its operation to ensure a perfect weld, every time. This means that the welds are strong and reliable, and will meet the highest quality standards.

The seam tracking sensor also speeds up the work of Kuka Robot. With this MINYUE Yaskawa Robot seam tracking sensor technology, manufacturers have the capability to automate the welding process. That means the robot can assist in making more parts in less time. It saves on workers and makes the whole production process operate more smoothly.

Seam tracking sensor used with Kuka Robot, you got a perfect and uniform weld line. The MINYUE ABB Robot seam tracking sensor is capable of compensating for any variation in the line, thereby ensuring a weld that looks neat, with no errors. This level of precision can be challenging to achieve with manual welding, which is why the Kuka Robot is so valuable for performing accurate welds.

Manufacturers want excellent results with Kuka Robot's seam tracking sensor technology. Because the robot is equipped with sensors that can pick up on the slightest variation in the weld line, MINYUE complex curved seam tracking sensor ensures that every weld is performed correctly. Instead, it results in welds that are strong, long-lasting, and without flaws.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

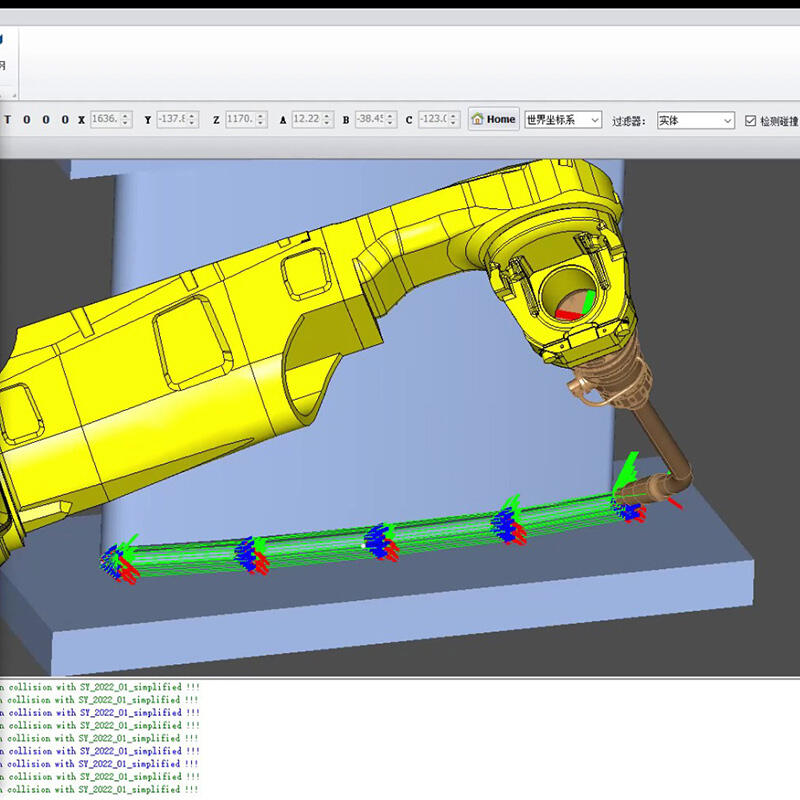

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

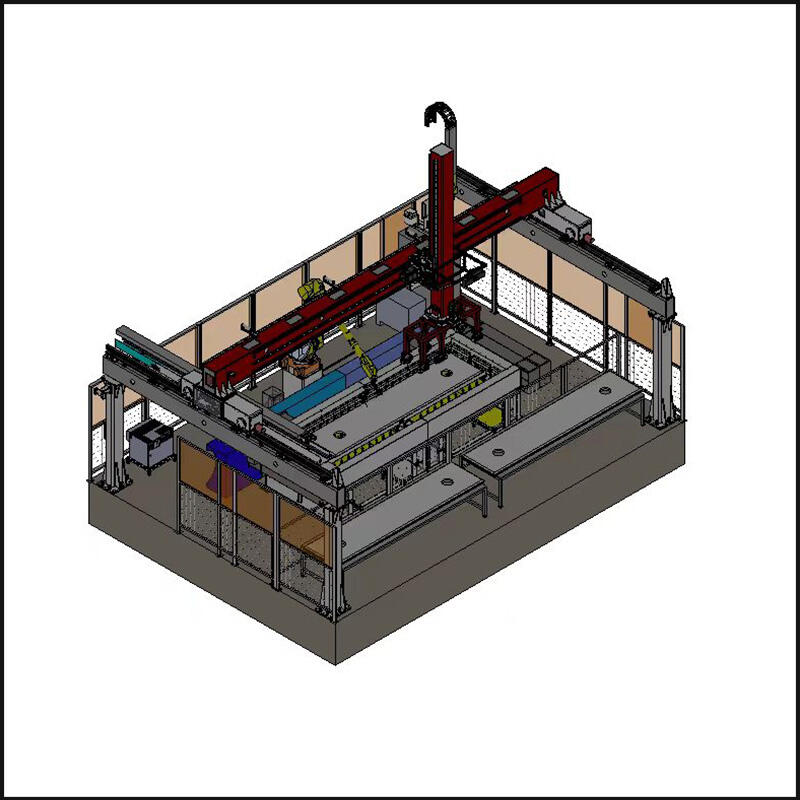

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.