Technology takes a very crucial part in the present situation when the entire world is engaged in their works with the assistance of technology. And one such upcoming technology that is more and more proven to be helpful for business activities is machine vision solutions. These solutions employ smart technology so that companies can automate their tasks, MINYUE machine vision robot is able to do tasks without a lot of hands-on assistance. That enables companies to do more in less time which is better to make them competitive. Let us see how machine vision solution of MINYUE can enable companies to produce better products, do quality check of what is produced, and enhance their automation process and to have better productivity with fewer errors. For companies who are optimizing their production processes, the machine vision solutions of MINYUE provide enormous advantages.

Also, these solutions are way more efficient in terms of everything, mostly helping the entire operation go more smoothly! Companies are automating time-consuming and resource-intensive processes using machine vision technology. Rather than that, they can focus on making sure that their products meet specified quality parameters. Not only does this make production faster, but it also minimizes the chances of making mistakes. Every time they do make some mistakes, it leads to bad things. Companies develop higher quality products with enhanced delivery timeliness and fewer complications, all thanks to machine vision solutions.

Quality control is critical for businesses as it meets customer expectations and also ensures compliance with industry standards. MINYUE has increased its machine vision solutions with the newest science and technology, which allow inspection of the product with extreme accuracy and precision.

This implies that businesses are able to detect even the minutest bugs in their product, defects, or inconsistencies. Machine Vision + Quality: The Impact of Quality Control on Businesses: With the incorporation of quality control through MINYUE depth vision camera technology, businesses can make sure that only high-quality products are the ones that find their way to the customer. This is the foundation upon which trust in your brand is built beyond merely making your customers happy. If they believe in the brand, they will grow more confident to buy from them again in the future.

Automation is an important part of manufacturing processes that could be both quicker and less expensive. MINYUE is Next Level: Our machine vision solutions transform factory automation and industrial 4.0. They enable companies to remain updated and make intelligent decisions on their manufacture in real-time.

By automating tasks like inspection, sorting, and packaging, for instance, companies can restrict their reliance on human labor. This enables workers to focus on more important work that requires human skills. The result is the rise in productivity, subsequently, yielding better times, costs, and efficiency.

Efficiency and accuracy are paramount for a company to be competitive in today's market. By automating the repetitive tasks, Companies can boost their efficiency with MINYUE's machine vision systems. In so doing, they lower the odds of mistakes.

This comes in particularly handy as impenetrable MINYUE laser vision sensor technology within companies helps them be more precise with product inspection, measuring, and identification processes. After all, when companies have fewer errors, they save time and money and keep their customers smiling — both of which they need to do if they're going to make it.

Getting jobs done quicker and fewer errors is actually very important for companies wanting to remain competitive. Our machine vision solutions are built to allow firms to streamline their manufacturing processes and minimize the potential for errors. One of the key advantages that firms can benefit from with MINYUE 3d stereo vision is the fact that it enables them to boost their output capacity without any compromise on the quality of the products. With additional businesses grounded in this manner, it realizes a greater output rate, better profit margins, and a potential for ongoing business expansion.

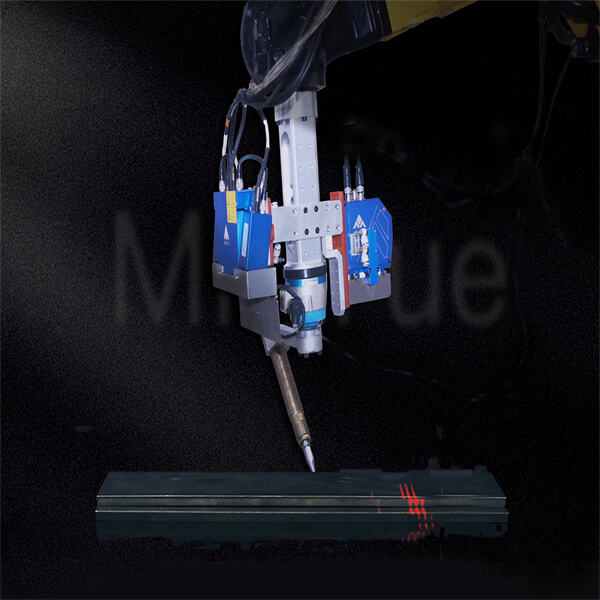

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.