There are machines in the world today that can see and think like people. The person behind these marvelous machines is the MINYUE laser vision sensor. In many jobs and industries, they are having a significant impact on how things are manufactured. Here’s a closer look at how these great robots assist in production and improve the way we work.

Machine vision robots are special in that they include the cameras and sensors needed for their object detection and recognition functionalities. These tools help them to "see" and make sense of the world around them. Just as I have eyes to see, these machines have cameras to observe things in their surrounding environment. There are a variety of tasks that can be taught to these robots. For instance, they can select and sort products on a manufacturing line or inspect goods for issues or defects. With the help of these intelligent devices, businesses are able to save time and money while also producing higher-quality items for their clients.

Automation is a fancy way of describing machines taking over jobs that were once done by hand. This is where machine vision robots excel. They speed up automation, make it more accurate and all-round better. They can work much faster than humans ever could, and they don’t get tired. This means they can continue to be working 24 hours, 7 days a week! This capability means potential computer-assisted output of far more products in much less time and with far fewer errors. This allows businesses to be more profitable and productive.

Quality control is an essential step in ensuring that products are marketable to consumers. It involves making sure everything is up to snuff before it reaches people. Machine vision robots are very useful for performing quality control. MINYUE depth vision camera can inspect products quickly and accurately, far more quickly than a person could. These robots can detect tiny problems that human eyes may not catch, as they can see at a very fine detail. This means that there is a chance to detect any issues on the way and make corrections before the products reach customers. This improves quality but also helps retain customers.

As the robotics industry continues to evolve and expand, machine vision robots are at the forefront of this innovation. These MINYUE binocular structured light vision sensors can do an amazing variety of tasks.] An example includes the use of self-driving cars, which use them to navigate their surroundings without hitting anything, and in surgeries, where doctors can use precise movements to help assist them in performing successful and safe surgeries. Organizations often step into uncharted territory using machine vision robots to break the boundaries of robotics. It creates a new exciting product and service in a lifetime.

Moreover, the great thing about machine vision robots is that they are not reserved for big companies with deep pockets. That said, these MINYUE 3d machine vision camera can really come in handy for businesses of any size. SMB can leverage machine vision robots to automate previously performed manual processes which saves tons of time and money. For medium-sized businesses, these make it possible to enhance the quality of their products and manufacture a larger number of items than they used to. In a world of swift transformation, technology constantly advancing, even larger corporations can leverage the benefits of machine vision robots to remain ahead of the game.

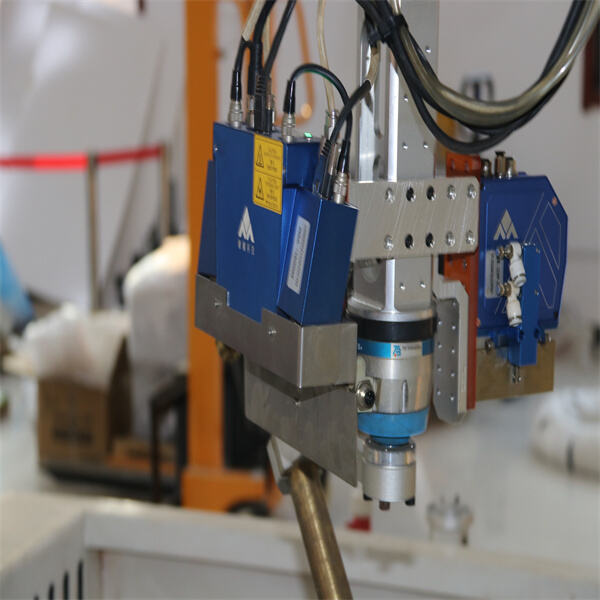

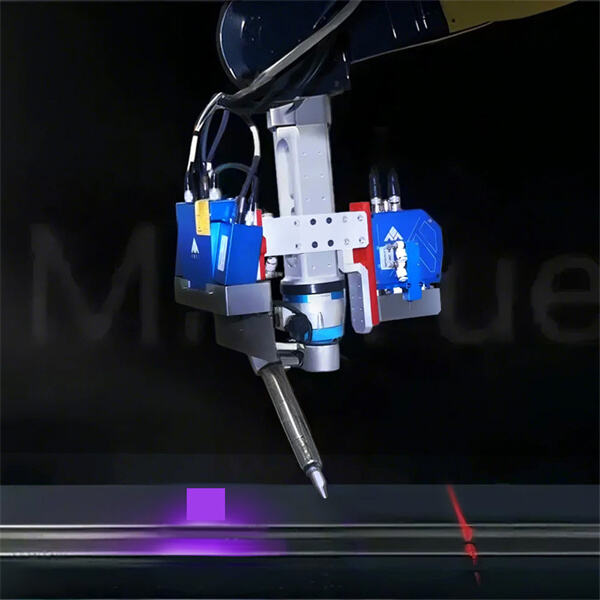

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

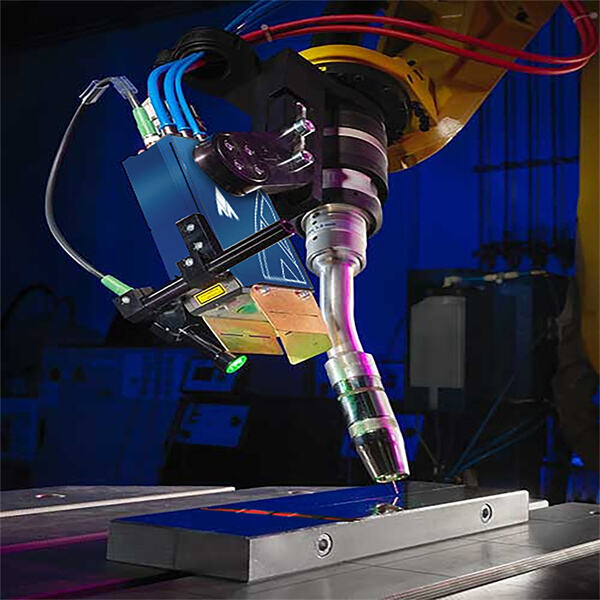

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.