Technology is evolving at a fast pace in the real world today. It is transforming the way we work, the way we play and the way we live our day-to-day. Industry 4.0: One of the most novel hot tech we hear today. This allows us to use intelligent devices and systems to improve our work, making it easier and better. Industry 4.0 is playing a major role in transforming the way things work, especially, in the welding industry.

The Industrial 4.0 centered around smart machine usage. These machines such as automated robotic welding can get the job done faster and more effectively than in the past. This means the use of robots and sensors in the welding field that aid the individuals performing the welding. This smart technology enables companies such as MINYUE to produce better products in significantly less time. This is good for the workers and for the consumers who are looking for quality products.

Industry 4.0 heavily relies on smart automation this includes automatic welding robot. This means using machines that are able to think and learn to carry out tasks such as welding. With smart automation, MINYUE is able to get their welding done faster and more accurately than was possible with manual labor alone. This saves time and money while helping to produce better and more stable welds. It is great to watch how machines can make it easier for workers to perform their tasks.

The welding process is changing in many ways with Industry 4.0 as well as automated welding robot. For example, there are robots today that can perform the same welding task over and over again without fatigue. This enables human welders to concentrate on more challenging and stimulating jobs that involve an increased degree of skills entailing less difficulty. Sensors can also determine the quality of the welds during the welding process. That means every weld can be perfect, and every in-house company can maintain the highest quality for their products. Take MINYUE as an example, the application of the intelligent technology of Industry 4.0 will not only help them to speed up welding, but also help them improve the final product quality.

One of the best things about Industry 4.0 in welding segment is that it promotes work faster and accurate. Because companies rely on smart things, like those at MINYUE, they can quickly finish the welding job and ensure the quality of the products. This allows customers to get their products quicker and with less issues. This is because when products are produced correctly and shipped on time, it makes customers happier and more committed to the company.

If you want to read about how Industry 4.0 can help create smarter solutions for welding? They are building welding systems that run quickly, accurately, and stably with high availability by utilizing advanced technology such as artificial intelligence and robotics. But this does not only have a positive effect on companies to achieve the objectives of lowering costs and optimizing productivity level, but customers also benefit by receiving superior quality products in less time.

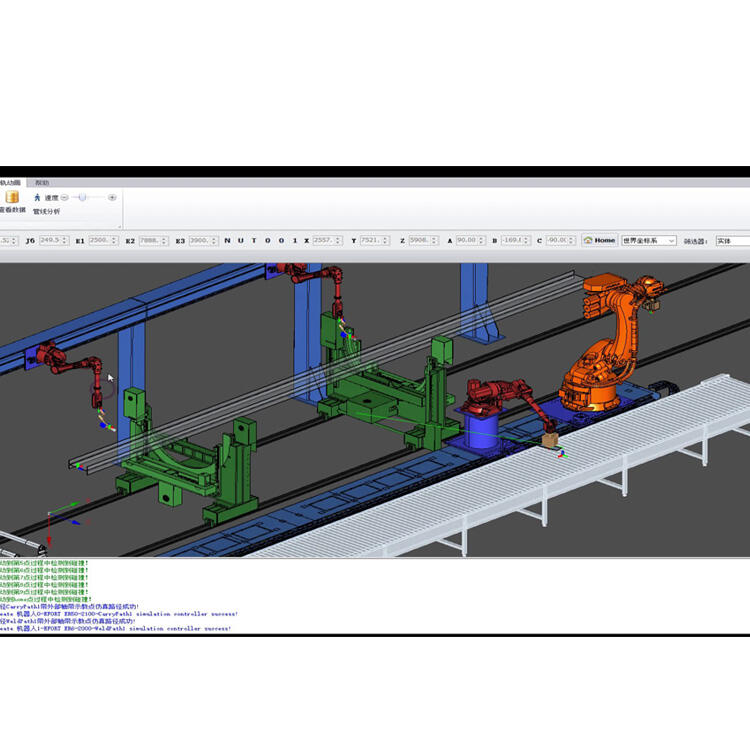

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.