Precision and speed are vital to quality product in welding. Weld is a process in which two pieces of metal or metal togethers are joined using heat. While welding, there is a possibility of a problem in a product quality, if it is not done correctly. A lot of changes have happened when it comes to welding due to new technology. Automated welding is a solution for supporting workers to perform their job faster, more effectively and safer. At MINYUE, we strive to provide our clients with the highest quality mechanized welding equipment that improves their comfort and efficiency at work. This allows workers to shift their focus to other important jobs, while the MINYUE automated robotic welding systems is handling the welding for them.

Automated welding machines can also help workers save time and operate with higher precision. Efficient means to do more in less time and accurate means to do the things rightly. Welding can be performed perfectly and uniformly by robots as well as special machines. That means fewer mistakes, every weld comes out good. The MINYUE automated welding process works with certain protocols in place just to make sure everything is done right. We want to automate the tools best for our customers at MINYUE, this means helping our customers by providing them with the things they need to make the best products. Our tools enable workers to do the right work without wasting time.

Robotic welding is a type of automated welding that utilizes robots and computers to accomplish welding tasks. These machines are programmed and instructed on how to weld. They take certain steps to ensure each weld comes out just so. This allows workers to not have to do everything manually, making welding quicker and easier. But as they say: doing things by hand, it could be time-consuming and prone to errors. At MINYUE, we offer numerous automated solutions that can be adapted to your specific needs, enabling you to achieve your welding objectives with ease. The machines adapt easily to perform different jobs — on a wide range of materials.

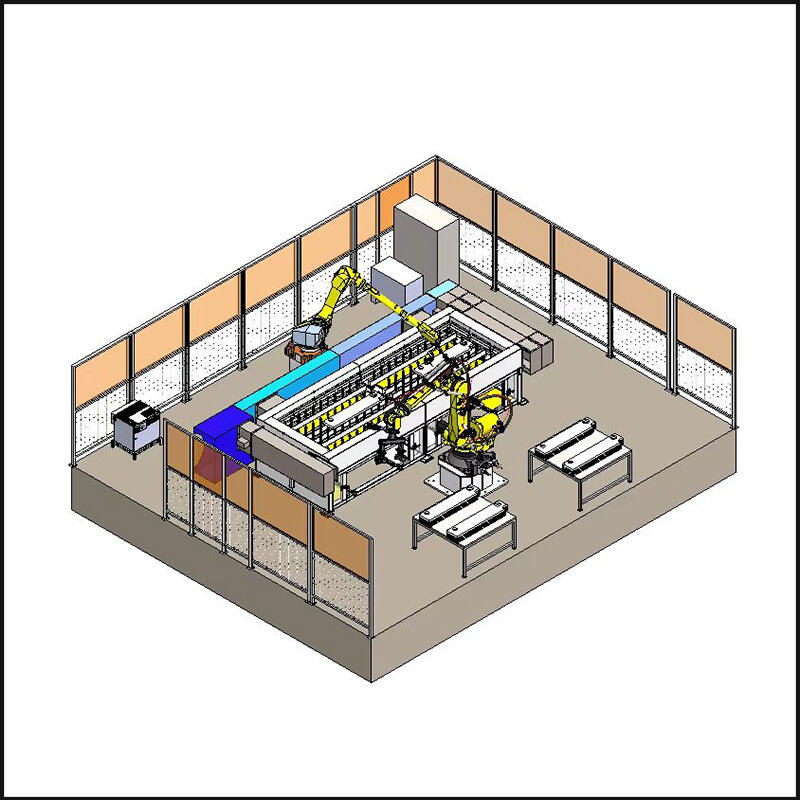

This allows companies to produce more products, at a quicker pace. Productivity is also how much work is done over a period of time. These MINYUE automated welding robot can work 24/7 without needing breaks, allowing them to produce more in lesser time. This enables organizations to serve their customers faster. We MINYUE understand that productivity is crucial for welding companies; therefore, we build the tooling to customize and automatically children welding tools to add to productivity, efficiency, accuracy, reliability, and cost savings. The tools help speed up the welding process, but also maintain a high level of QA over the welds as well.

Welding automation has already empowered welding by improving efficiency, quality, and productivity. This also indicate that these new technologies have made a great impact on the overall process of welding. At MINYUE, we are pioneering this shift with innovative automated welding solutions that redefine the welding landscape. We want to improve the way companies operate, we want to streamline and help businesses do more with technology. We want to make sure that all the companies we work with can are getting in on these advances. The Future of Welding is Bright with MINYUE automated welding machine! We will be investing further in our RandD to come up with innovative new solutions to make welding easier and more efficient for all.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

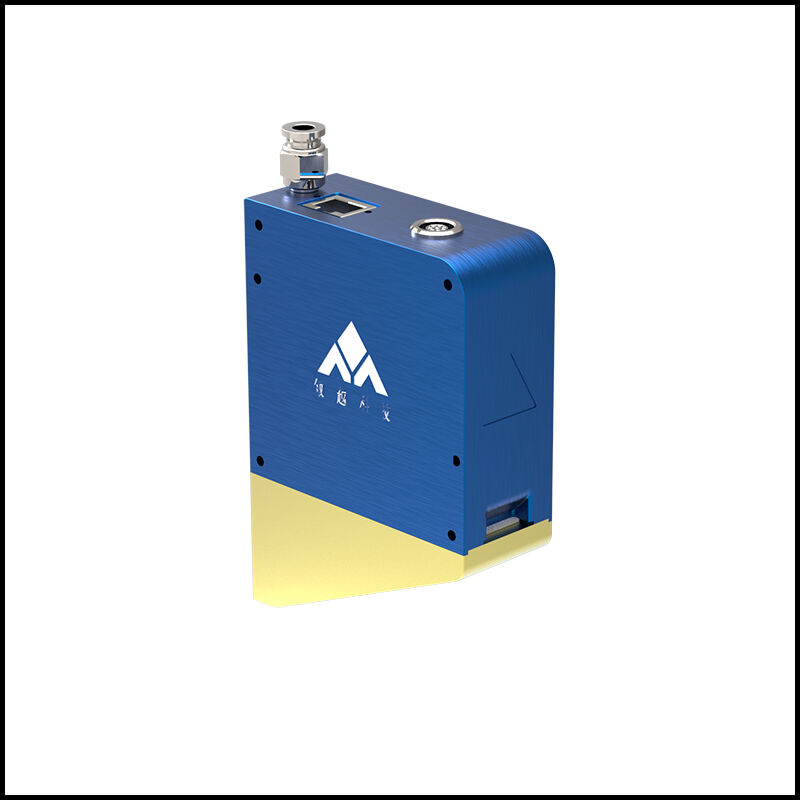

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.