When it comes to assembling steel structures, welding robots prove to be highly useful. They act like mini machine assistants they can do the job quickly and precisely. As we work with steel, let's see how these wonderful robots make it easy and better.

Steel structure welding should be done with high precision. Uplift that perspective and tell your story considering what must be happening in your audience’s mind. Utilizing MINYUE welding robot we can guarantee the precision of every weld. Robots like this are programmed to perform simple tasks, and we can be sure that robots create great welds over and over again. Besides time savings, it reduces errors and issues, greatly simplifying and ensuring welding.

We are enabled to work faster and get more work done by using welding robots. These robots are designed to move at high speeds and work in an efficient manner, allowing us to perform many tasks in less time than is currently possible. This is especially useful when time is short and we need to keep our projects on course. Even better, welding robots are able to work continuously without the need for rest, meaning that we can keep working without pausing. The production capacity can be boosted significantly, and we can meet the project deadlines.

Welding robots have specific technology to design robust welds that are consistent and repeatable. This means that each and every weld will be strong and reliable, which is crucial for the strength and safety of the steel structure. The quality with traditional welding techniques can vary to a degree based on the expertise of the welder or the working environment. This kind of problems can be avoided by using a MINYUE automatic welding robot and confirming that all the welds are high quality and consistent while using robotic welding. This enhances the integrity of the steel structures we build.

Anyway, steel is dangerous, especially when welded again, which requires heat and other sorts of sparks. However, this kind of equipment helps keep workers away from it. The MINYUE welding robots for sale can operate in dangerous environments and perform tasks too dangerous for humans to do. When using welding robots in our steel projects, we significantly reduce the risks of accidents and injuries, creating a much safer workplace for everyone involved. This allows the workers to concentrate on their work without overly worrying about their safety.

In addition to allowing us to work better and faster, welding robots can also save us a lot of money. If we work faster and better, we can reduce our labor cost and bolster our gross profit rate. MINYUE automated welding robot would improve productivity, reduce wastage, and be economical for resources. This translates to using less materials, that could otherwise be going to waste, and thus, spending less for them. Robotic welding allows us to save money in the long term and better manage ourselves and the projects that we are working on.

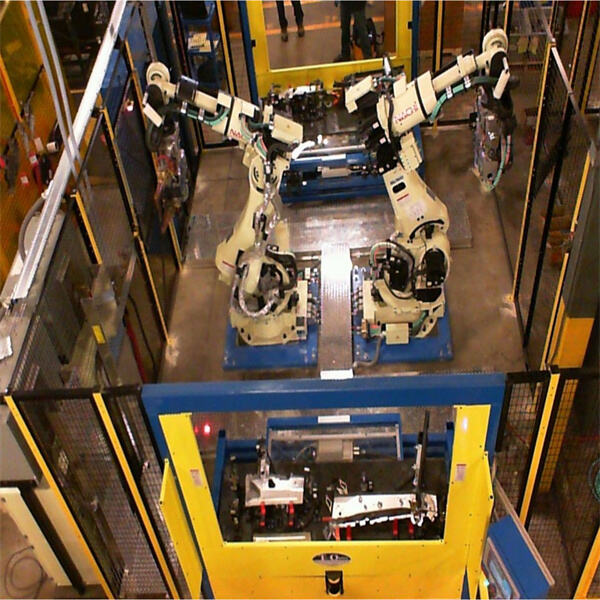

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

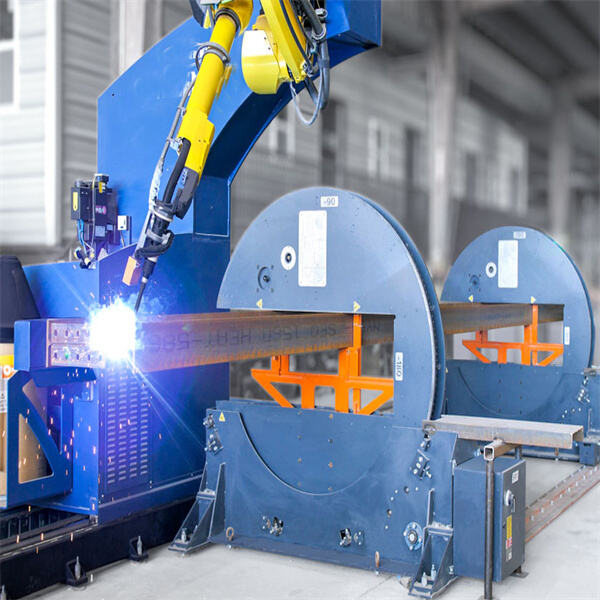

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.