Sensors are special helpers that help us observe things that are hard to see with the naked eye. They are trained to detect minute details and rapid movements that we might miss. A complex curved seam tracking sensor as well as laser seam tracking sensor from MINYUE is a smart type of sensor. Although this name may appear overly long and complicated, it serves a critical function that allows us to perform many tasks.

Have you ever taken a good look at a piece of cloth — a piece of fabric — with plenty of twists, turns and curves in it is seams? They can be super fiddly to sew together perfectly. This is where sensors such as MINYUE automatic weld tracking sensor come into play. They can trace the twists and turns of the seams, and they can guide the sewing machine to know precisely where to sew. The title helps make sure everything lines up properly and looks good in the end.

Complex curved seam tracking sensors and real-time tracking sensor are magic lunchables for your sewing machine. They can feel the contours of the fabric and change the stitching accordingly. to say, when the fabric is bending and curving in various directions, the sensor will ensure that the stitches are left straight and neat. It sure feels like you have a genius assistant standing right next to you — guiding you every step of the way to perfect sewing.

In big factories where a lot of same type of products are created each day, precision and accuracy are key factors. Even small errors can cause big problems down the road. This is why advanced sensors, like complex curved seam tracking sensor as well as MINYUE real-time laser seam tracking sensor, is considered so important in the manufacturing process. They ensure that every product is made in precisely the same way every time. This saves a lot of time as well as ensuring that everything works perfectly when it is complete.

Imagine attempting to hand sew a complicated pattern. It would take a long time, and you would have to focus hard trying to get it right. But using sensors, sewing machines can do work much faster and with more precision than any human could. That allows products to be produced in less time and allows companies to operate more efficiently and productively. It is like a hidden weapon for increasing productivity and quality of the goods being produced.

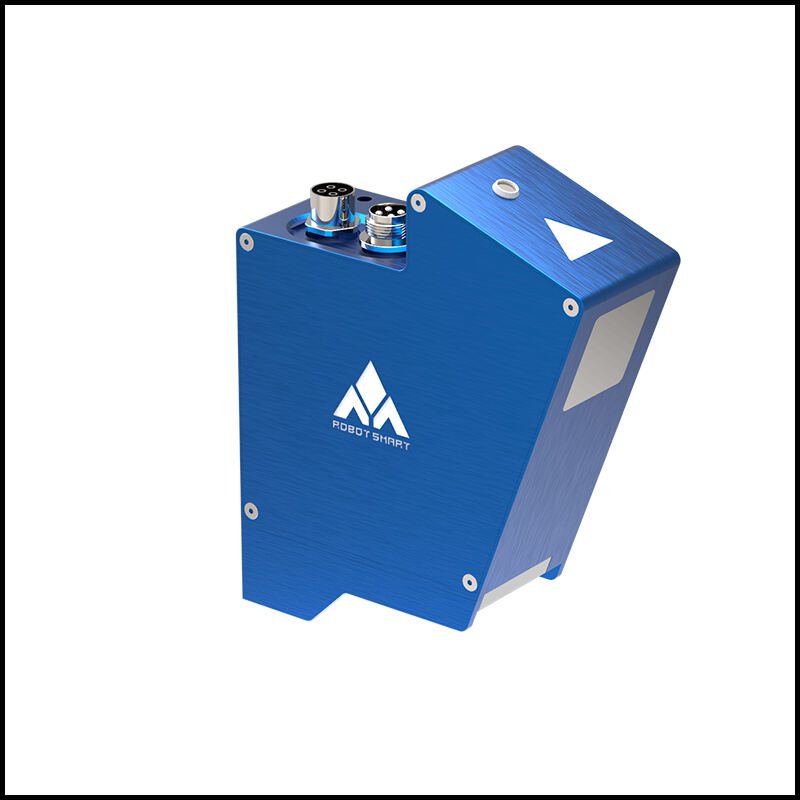

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

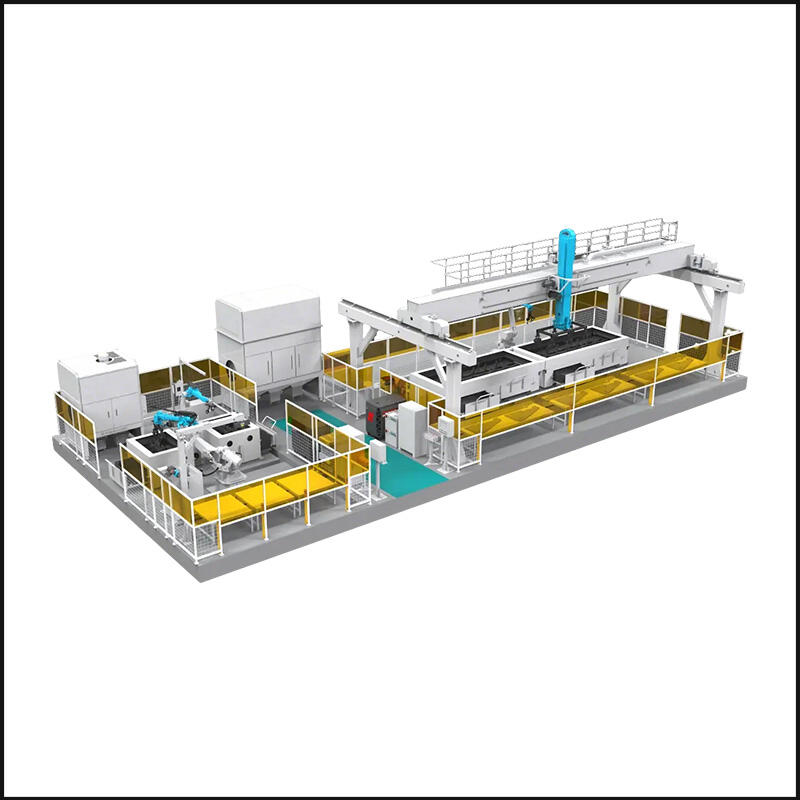

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.