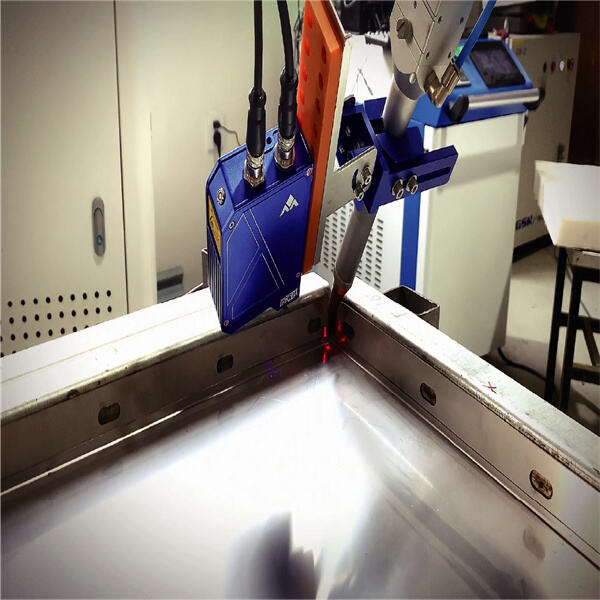

The ABB Robot seam tracking sensor is a non-standard sensor that helps robots to get perfect welding. Welding means to superheat two pieces of metal to form a single piece of material in a process where the material cools after the heating process has taken place. It plays a vital role in the fabrication of many of the tools that we use regularly in our lives, from cars and bicycles to shirt pockets and swings

Consistency is very important when welding, doing it the same way every time. If these are not welded in the same way, the parts of metal may not fit together properly. This robot laser welding machine robot seam tracking sensor ensures consistent welds, which improves weld quality and safety.

This means factories can be confident their goods are being produced to a high standard, using this sensor. This is particularly important in the case of automobiles and aircraft, where even a small welding error can lead to significant issues

Efficiency is doing things speedily and effortlessly. The ABB Robot seam tracking sensor helps robots to operate at a greater speed by enhancing their perception. This automated welding robot allows factories to produce more in less time and can be beneficial from a cost and resource perspective.

Yet there's a whole store of good reasons factories are employing the ABB Robot seam tracking sensor. A big reason is that it automatic welding robot helps ensure that products are high quality. Factories can rely on their products to last longer and perform better by ensuring that quality welds are achieved every time.

This sensor also saves time and money for factories. If they do their jobs better, they produce more products in a fraction of time and ultimately meets deadlines and fills orders in little time. This welding robots for sale helps the company expand and become more profitable.

One other notable aspect is its durability. It can withstand harsh conditions in a factory, where it may be hot and dusty or likely to face other challenges. That welding robot manufacturers means the sensor will survive in the field for a long time, continuing to enable robots to make great welds for many years to come.

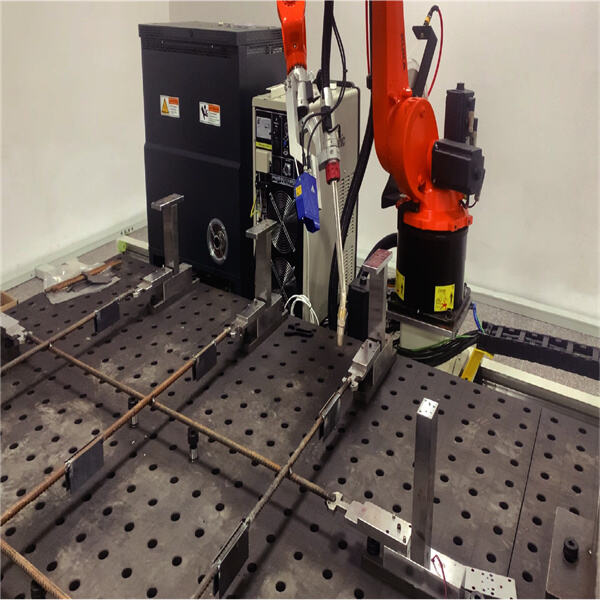

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.