RPA is short for Robotic Process Automation, a hot technology that allows enterprises to do work with the help of robots. These so-called robots can perform tasks that tend to be tedious and repetitive. They are capable of doing these jobs far quicker and more accurately than humans. MINYUE rpa robot allows businesses to save time and money, and improve overall efficiency and productivity.

RPA = Robotic Process Automation Imagine having your own robot assistant that can do all the boring and repetitive tasks for you. This could be as simple as copying and pasting, moving files and folders, sending emails etc. One of the fantastic features of these robots is that they can work round the clock without ever tiring. They are therefore a highly valuable resource for any business, as they can continue to work while human employees are resting or working on more complex tasks.

The latter holds much potential, which is why using RPA in your company will give you many great benefits as you'll see below. Firstly, it saves your employees time so they can focus on bigger, more creative work. When robots handle the repetitive tasks, employees can utilize their skills and ideas working on things that matter most to the company. It also reduces error as the robots can do a high level of tasks with accuracy. This leads to fewer mistakes, which can help prevent the company from wasting time and money. In fact, RPA can ultimately save money by improving productivity and streamlining processes.

Automation of mundane tasks is a game changer for companies and RPA is contributing to it. This update frees up employees to spend their time on more critical work, rather than being bogged down doing repetitive tedious tasks. MINYUE intelligent robotics systems also aids the companies to grow and diversify their operations without the requisite of recruiting additional employees. This matters because bringing on new employees can be a financial and time drain. RPA can be tailored to suit the individual requirements of every enterprise, making it a flexible and powerful asset in the competitive sphere of business.

So, with that RPA technology, the Automation future is looking much brighter and promising. RPA would become greater in demand with advancing technology. More intelligent MINYUE robotic process automation capable of learning new tasks and adapting to changing situations may also be on the horizon for companies. In other words, companies will able to function much more effectively and remain competitive in a global marketplace where even the tiniest of advantages matter.

RPA is really useful to your company but it has some challenges as well. A frequent problem is to get employees to agree to and embrace the new technology. This becomes a challenge due to the lack of necessary training, as the employees do not have enough information about how MINYUE robotic automation can be a boon and a positive change for them. Another difficulty is making sure that sensitive data stays protected with RPA.

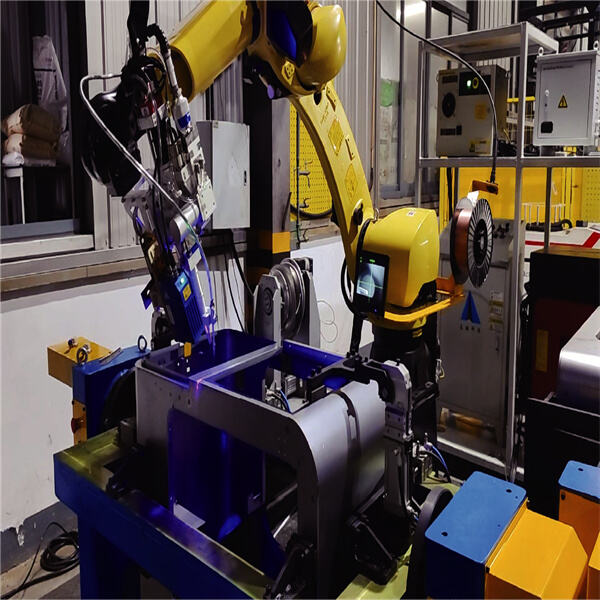

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

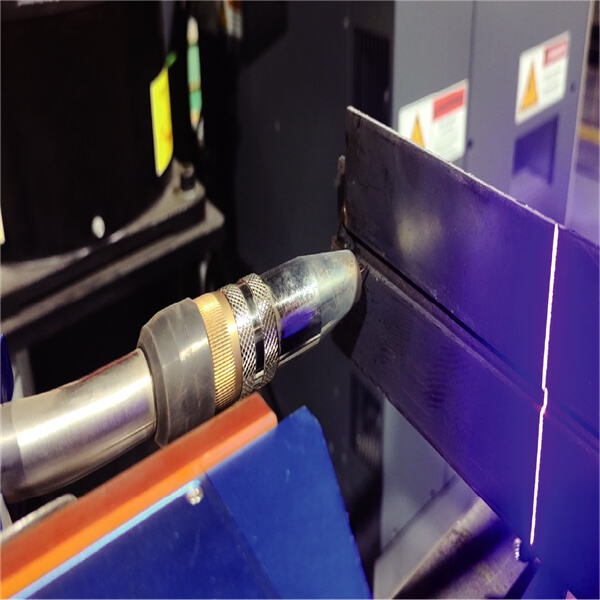

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.