The term RPA robot means Robotic Process Automation. That means it's a generative technology that mimics human action across the computer. Picture you at your computer — clicking, typing, copying and pasting. An RPA robot can perform all of them as well! It is trained to follow a procedure so it can complete tasks quickly and with no error. This allows it to be very useful in many types of work. Best things of Doing Business Using RPA Robot One of the main advantages is that RPA welding robot can complete the same tasks at a significantly faster rate than human beings. For instance, when, someone needs to fill out a similar form repeatedly, an RPA robot can do that fast which means a lot of time can be saved. So it saves you time and money because a robot can do that for you instead of a human.

The other great thing about RPA robots is that they don't get tired and can work around the clock. Unlike humans, who require breaks, sleep, and time off, RPA handling robot can operate continuously. This will allow your business to operate in faster and more efficiently way. If you have a robot doing repetitive things, then your employees can do more value-added, creative things, which is priceless. The first step in what you should do when you want to use an RPA robot in your business is to determine what tasks you want the robot to take over. Consider those jobs that are time consuming or very repetitive. Now, you must program the robot to perform those tasks one by one! It is the equivalent of training the robot to do its work!

Once you program the material handling robots you just let it perform these tasks for you automatically. This means it can do the work all by itself once you set it up! But, you need to check on the robot very regularly. This also allows you to properly test it and adjust if necessary. It’s similar to checking on a pet or a plant; you want to ensure everything is fine!

In what is to come, RPA robotic spot welding are going to advance in superior ways. They may one day be able to teach themselves new tasks — similar to how we pick up new skills. They might also collaborate with different robots to tackle more complicated tasks. Such collaboration could help companies become more efficient and productive. Over the years, RPA technologies will become more advanced, and robots will continue to help make work easier for everyone.

Many worry that RPA robotic welding cell would eliminate jobs for humans. But that is not true! While RPA robots can interact with humans, they are not there to replace them; they are there to ease their workload. RPA robots can help to free up humans from repetitive and boring work to focus on more important and creative work that requires thinking and finding ways to solve complex problems.

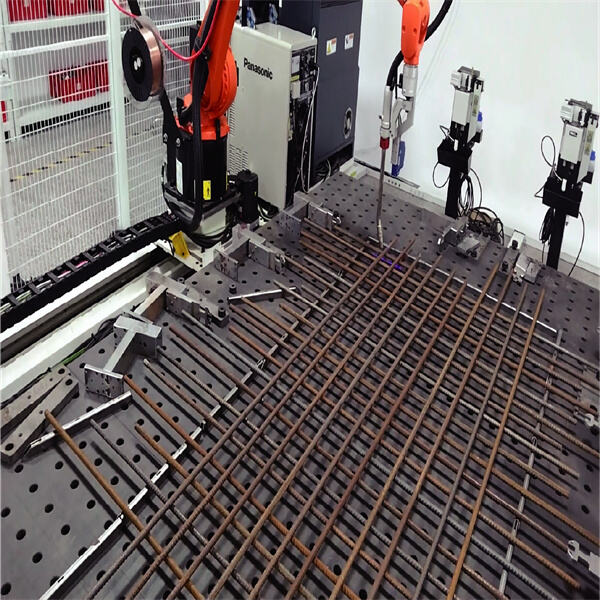

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.