Robots are transforming the way that many different types of work are handled throughout today's job market. A robot is a machine that can perform many tasks, which can perform functions that human used to do. Being an incredible technology that is helping organizations do things much faster, efficiently, and accurately than probably ever before. So, now, let us discuss a bit on Robots are changing the landscape of several of the working fields and settling down with us on a daily basis;

What kind of robots can help businesses do more work with fewer mistakes? That is why robots can work all day and all night long without getting tired just like superheroes! They can perform jobs that are dangerous or monotonous, freeing humans up to do more creative and interesting work instead. In factories, for example, robots are used to assemble products, package products into boxes and inspect for quality. This means that businesses will be able to create more products quickly and in the same time saveMoney. If robots take care of the hard work, then people can devote their time towards gaining inspiration and enhancing their work.

As robots help businesses streamline operations, they are simultaneously altering the types of jobs people hold. Bots are doing some jobs that used to be done by people. This change can cause people to be fearful of losing their job. But it’s worth noting that robots also create jobs. For example, humans will increasingly be required to design, program, and care for robots. These jobs utilize new skills, and if workers can learn these new skills, they will be able to reap the benefits that robots will be bringing to the workforce.

One of the greatest advantages of robots is that they can increase the pace of business process dramatically. Robots do their functions faster and much more efficiently than humans, which means they can create much more goods in very little time. In agriculture, for instance, the use of machines to sow seeds or collect crops makes them easier and cheaper. In warehouses, robots pull things off shelves and pack orders faster than any human could. Robots can improve the operations of a business, allowing a company to keep up with the fast pace of life in the modern era, putting pressure on everyone to do things quickly.

Robots not only assist regarding the rapidity, they also assist the businesses to manufacture superior items. Because robots can accomplish very precise and repetitive tasks, there are fewer errors and defects in the goods. In car factories, robotic welding automation help weld various parts and paint cars perfectly without errors and their productivity increases manifold having a little break only. With robotic assistants, businesses could be confident their products were produced under strict quality conditions and fulfill customer expectations, a very crucial element in keeping customers happy and wanting more.

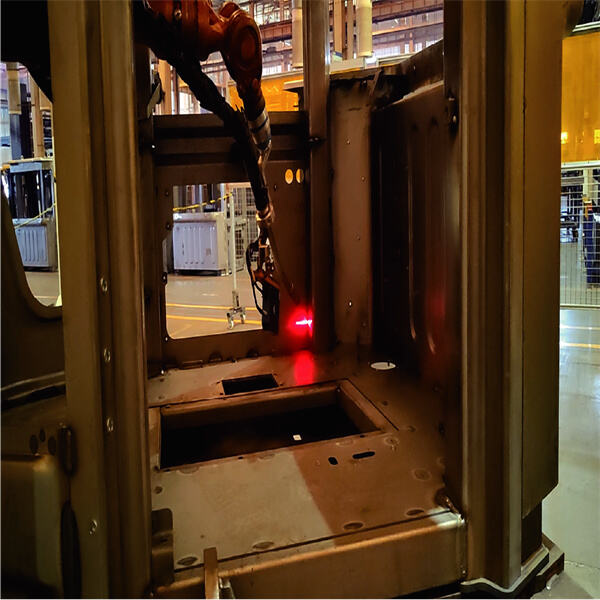

This is largely being done with robots as part of the new Industrial Revolution, whose name is often Industry 4.0. This new era is defined by the adoption of digital technologies, laser welding automation, and data exchange in factories and workplaces. This transformation is led by robots, which assist corporations in utilizing data to improve their business decisions. Robotic automation indexing helps businesses to stay updated with the changes happening in the world and benefit from the unique opportunities this Industrial Revolution has to offer.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.