MINYUE developed advanced robot programming software to revolutionize the way robots work and execute tasks. These smart tools mean that robots can do their jobs more effectively and more efficiently than ever before. In this article, we will check how this MINYUE Robot offline programming is going to help a robotic scout in a vast number of different roles and industries.

MINYUE-robot programming software A very helpful robot programming software that allows robots to work quickly and smart. It employs specific sequences of instructions, known as algorithms, to assist robots in contemplating their jobs and making decisions on their own. That means robots can do their jobs faster and with fewer mistakes than they did before. This does not just help save time, but also money for companies, which is very critical to their growth.

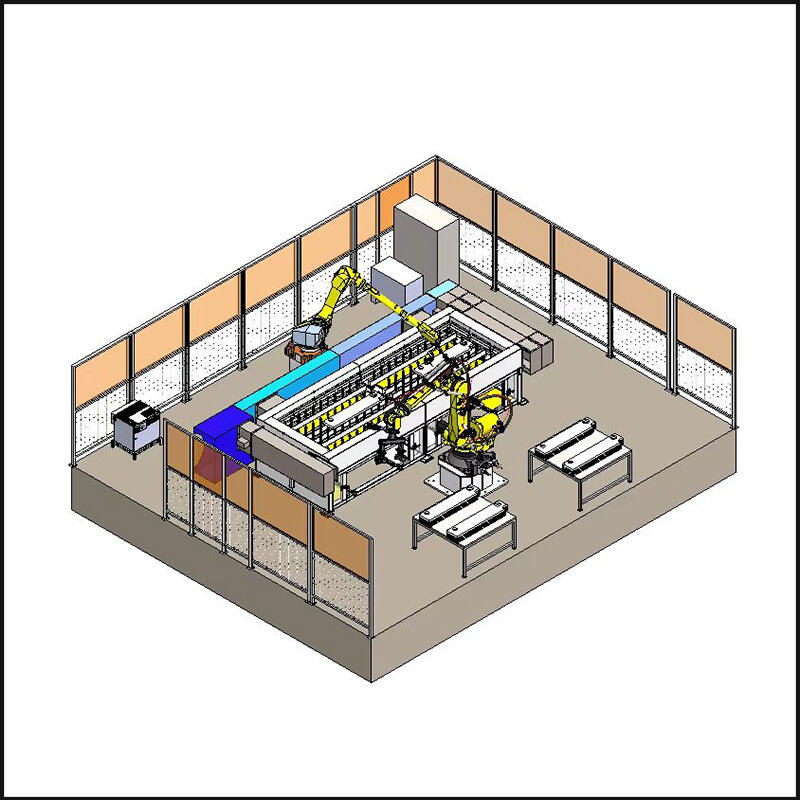

MINYUE's robot programming software is extremely useful to factories and warehouses. By teaching robots to collaborate with each other effectively, this can help these areas run more efficiently. Businesses have an easier and faster work when robots are programmed to coordinate with each other. With this smart software, businesses can also rely on fewer human workers, resulting in massive cost savings. This allows businesses to concentrate on scale and optimizing business operations.

With MINYUE's smart programming tools, companies can do even more with automation. When companies teach robots to take on tough and complex jobs, they have the ability to drive their productivity and output. These smart tools also enable robots to adapt to variations in their environment, allowing them to maintain high performance regardless of external changes. MINYUE embodied artificial intelligence adaptability is crucial in the fast-paced world we live in today and enables organizations to remain competitive.

Their AI-operating robot programming software makes complicated things simple enough for robots to manage. Machine learning enables robots to learn based on experience and become better over time. MINYUE Welding intelligent decision system allows robots to perform a wider range of jobs and to do them with greater skill and precision. This makes robots welcome colleagues of human workers, who can then put their efforts to more creative and complex work.

MINYUE's software really transforms factories' operating and doing their job. In turn, automating this production line enables companies to produce more material and do less human labor. MINYUE intelligent robotics systems flexibility not only ensures that enterprises keep up with the rapid change in the economy but also ensures that they stay competitive in a constantly evolving world.

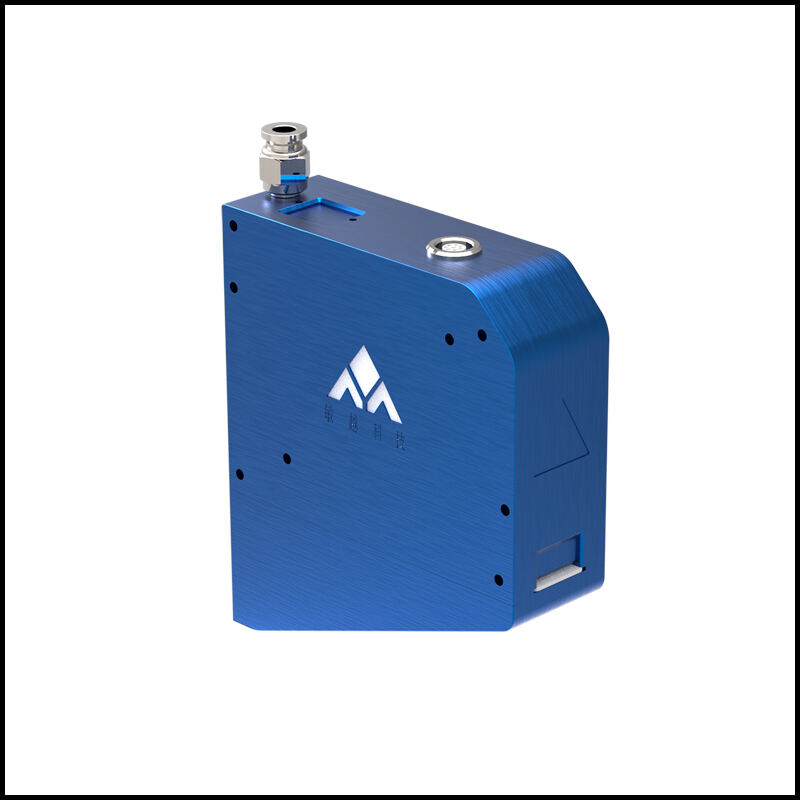

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

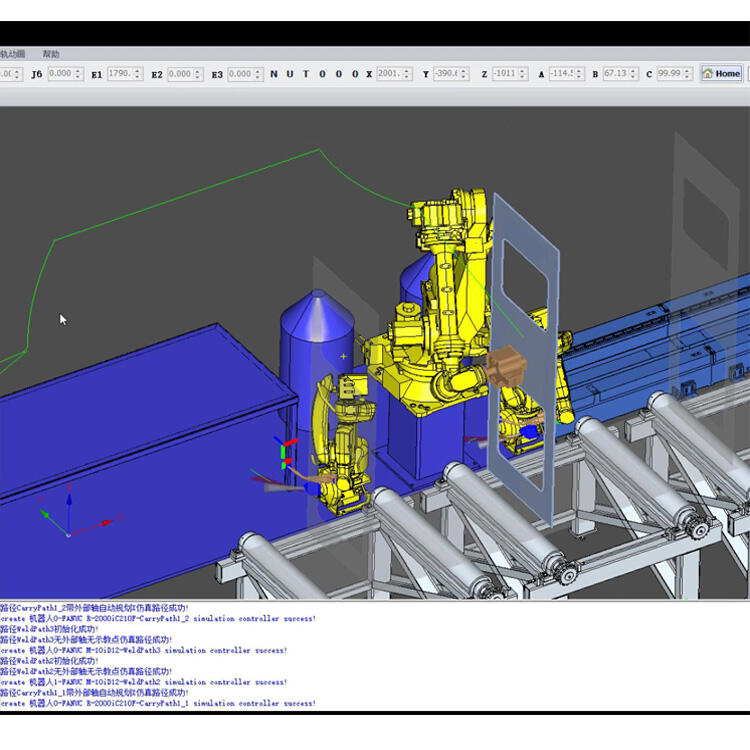

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.