Laser triangulation is pretty neat technology which is useful us measure distances very accurate. It employs lasers to determine how far away something is from where we are standing. Lasers are a unique type of light that can go for long distances. Let us find out more about laser triangulation and how it works with MINYUE.

But you analyze distances through a laser beam, that is 3d laser triangulation. It does this by shining a laser light on an object, then measuring how long it takes for the light to reflect back to the source. Since laser light reflects off the surface of objects, it bounces back to the sensor. math, and special tools we can figure out how far away the object is. This tool has been good to work with several different works from factory working to enhancing assistance robot

MINYUE laser triangulation sensor is a measurement technique based on geometric and physical concepts to measure correctly distances. When the laser beam reaches an object, it makes a triangle between the laser, the object and the sensor that sees the light bouncing back. By measuring the angles and distances within this triangle, the system can calculate the exact distance to the object.

You are skilled in scanning, data acquisition, data processing, etc. Employing high-resolution components and clever computer algorithms, the technology of MINYUE is able to achieve astonishing precision in distance measurement. Precision up to this level is crucial for jobs that require accurate measurements, like the production of planes or vehicles.

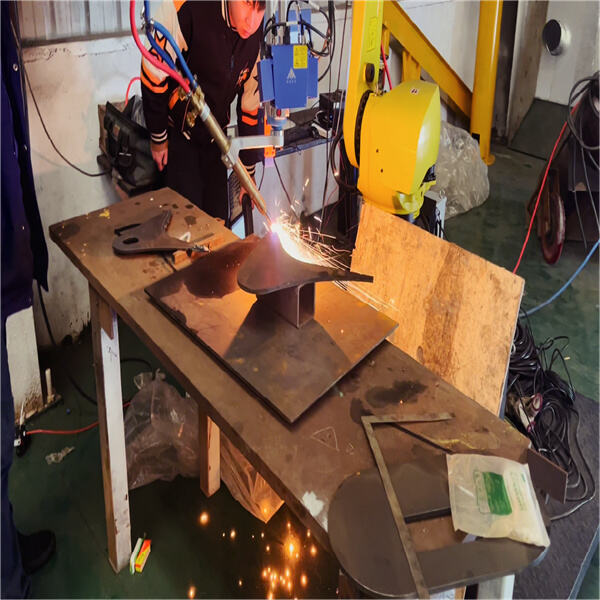

Laser triangulation technology is widely used in the factory for dozens of tasks and uses. An example of this is when verifying the quality of products, triangulation sensor can be utilized to analyze the product sizes and detect any problems or defects. That means workers can instantly tell if something is made correctly or not.

Laser triangulation in robotics helps machines understand their environment and engage with objects. This technology allows robots to avoid obstacles and perform safely alongside humans. Furthermore, laser triangulation is a key technique in 3D scanning to build up precise digital representations of objects. This allows us to build up a very accurate virtual picture of an object.

MINYUE is at the leading edge of advances in laser triangulation technology, especially for 3D scanning. Our systems can capture detailed 3D images of objects with exceptional accuracy and speed. These serve as the most beneficial for things such as architecture, archaeologists, entertainment where 3D models heck for everything because it is essential to be defined and designed.

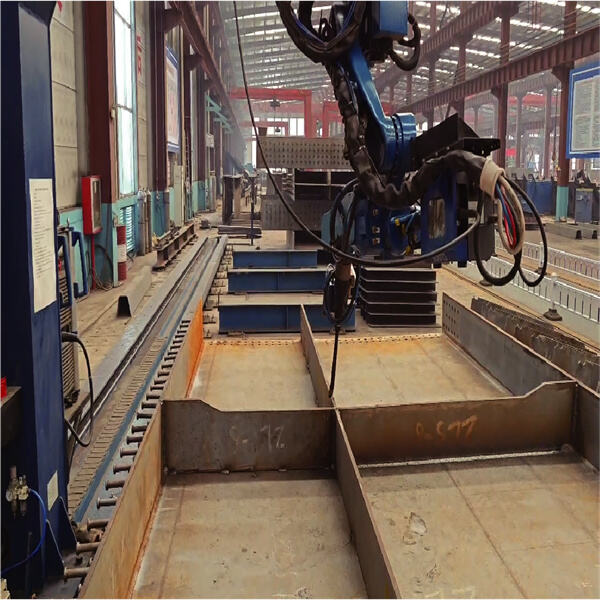

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.