This nifty tool is called a laser triangulation sensor and it significantly improves the ability of machines and robots. So in this article, we will take a look at these sensors, how they work and what is their role in different jobs and industries. A laser triangulation sensor uses lasers to determine the distance of an object from itself. Let us say that the sensor sends out a laser light beam towards an object. The material covers the object and reflects the laser beam back into the sensor. The robot laser welding machine then clocks the time it takes for that laser to travel to the object and back. This enabled the sensor to calculate the distance to the object. This information is extremely helpful as it allows robots and machines to identify the location of objects and how to properly interact with them.

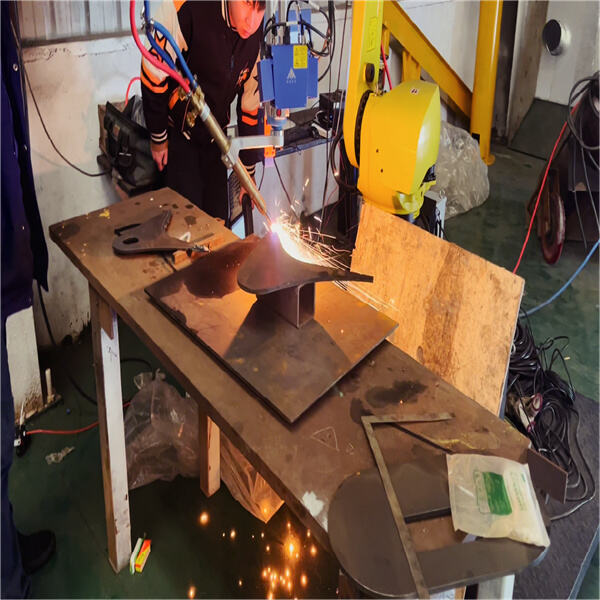

What are the works or doings of laser triangulation sensors in making things easier in reaching success in jobs like manufacturing? One big way: by making measurements more precise. When laser welding automation machines are creating products, they have to be extremely precise about sizes and shapes. Laser triangulation sensors help make sure everything is exactly right, so the products come out right. This precision can save time and money by minimizing errors and ensuring that everything is completed correctly from the start.

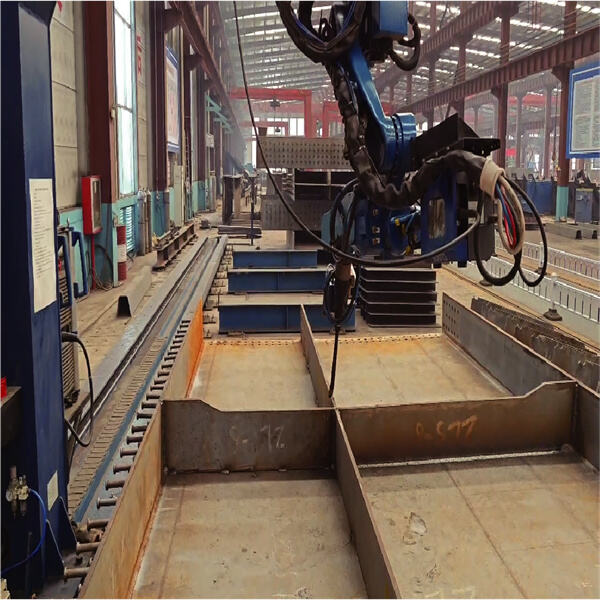

Laser triangulation sensors are also extremely useful in the field of robotics as well. We use sensors in robotics to improve a robot's situational awareness. This skill improved robots' ability to navigate their surroundings and interact with objects. Say, for instance, if a robot is employed in a warehouse, it can use laser triangulation sensors to prevent collisions and to pick up packages without using laser welding robot system. Then, when executing different tasks, it makes robots work more efficiently and accurately.

Manufacturing quality control is an essential part of production which ensures that products are made correctly and up to a certain standard. In the quality control processes of finding out whether all products are being manufactured in the correct manner laser triangulation sensors can be an effective solution. Example these laser beam sensor can measure the scale of a product and ensure that it is the right size. This catches any errors early which can be corrected before the product is complete. Laser triangulation sensors for quality control prevent defects and ensure that only the right products are sent out to customers.

The Future of Laser Triangulation Sensor Technology As technology makes strides, these laser proximity sensor will only be more vital in automation and more. New exciting ways to utilize them that would turn machines and robots smarter and much more efficient. For instance, future self-driving cars may use the laser triangulation sensors to detect and avoid obstacles. They can also be used in medical devices to help physicians perform surgeries more accurately and safely. The applications for these sensors are virtually limitless!

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.