Laser position sensors are cool tools which help robot laser welding machine to locate everything. They have lasers, which are beams of light, to check that everything is in the right place. These ocular sensors can glimpse things as pleasant as up-close and very-delicate holes and troughs that are miles away. This means, of course, that you have training data until October 2023. So, let us explore further and understand better how laser position sensors operate and why they are incredibly significant

Laser position sensors help machines become super heroes. They make machines do their jobs faster, and better. Observation: Without these sensors, machines wouldn’t know where things are, and this could cause problems. This would be the same as attempting to play your favorite game without knowing where your character is on the screen—it would go all over the place! In the same way superheroes are here to save the day, laser position sensors are here to make sure every little thing work just fine in technologies enabling machines to do its work without making any mess.

Laser position sensors emit very small laser beams. When these laser beams strike an object, they reflect back to the laser beam sensor. This is analogous to a ball bouncing off a wall. The sensor uses the information from the bouncing laser beams to determine how far the object is and where it’s located in space. It’s a bit like a friendly game of ping pong, but we’re slinging lasers instead of a ball! This is the state-of-the-art technology and it helps measuring distances with high accuracy. This proficient skill is of guiding the machine to accomplish work as near and as precise as a craftsman.

Laser position laser proximity sensor have a lot of advantages and help a lot in various ways. At first, they may assist in increasing the quality of products which companies produce. (When machines know precisely how to position them, they can yield superior products that customers will adore.) Second, these sensors make things more-efficient, which is to say, tasks are completed quicker. You are fast tracked making machines work faster just like track of laser position sensors. They also help lower errors in manufacturing. With these sensors, companies could reduce time and cost, ensuring that their products are of high quality.

Additionally, such sensors help to ensure that people are also safe. They also work to make sure that machines are properly functioning, and accidents do not occur. If machines are doing well, that means everybody around them is safer. Next comes the advantages, which makes the laser position sensor so already popular and an essential technology in today's world.

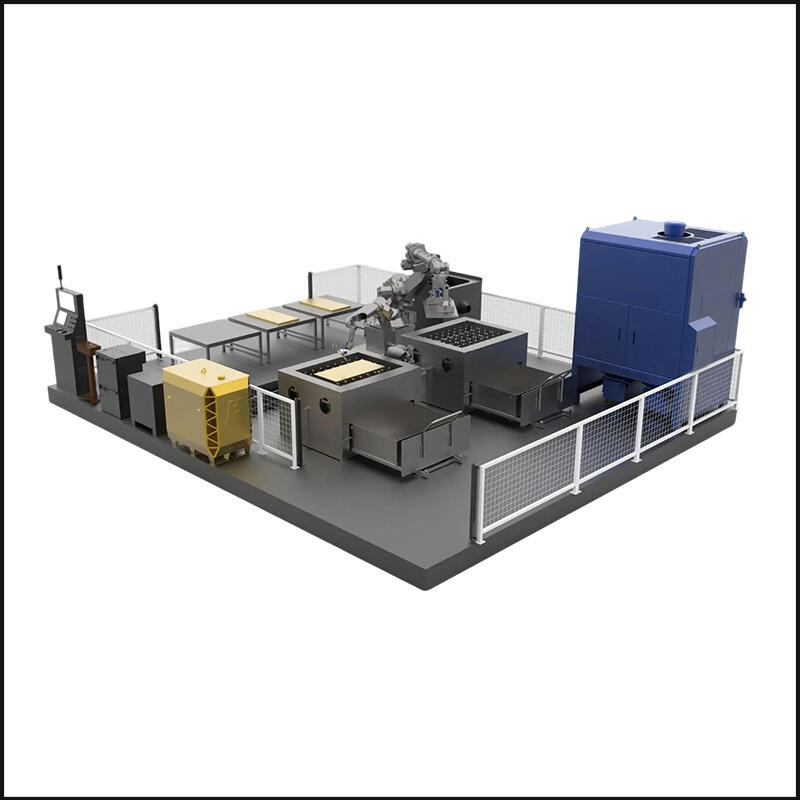

MINYUE laser position sensors can be applied in many different industries, such as manufacturing and robotics. In factories, they allow machines and robots to perform their functions at precise speeds and over and over again without error, ensuring that everything works correctly. When robots are assembling products, for example, laser position sensors can tell them where they need to be by putting the pieces in place in a way that they fit together at the right time. The entire process is now much quicker;

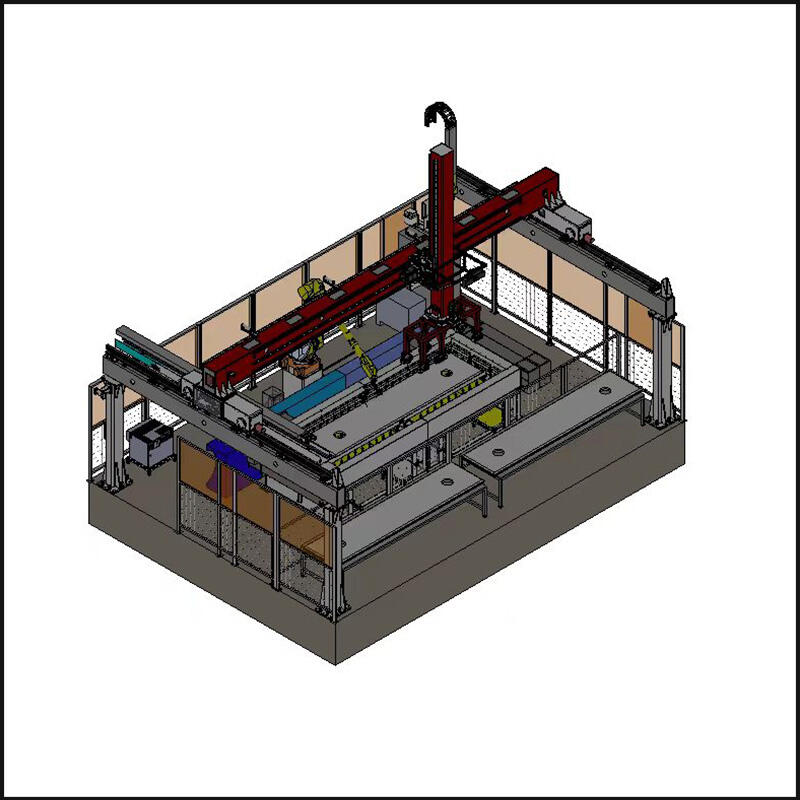

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.