Cutting machines are instruments that makes cutting quick and easy. They are useful for businesses that are required to slice materials like fabric, paper or plastic into precise shapes and sizes. MINYUE and similar companies create these automated cutting machines so that workers are able to save time and enhance their work. An automatic cutting machine allows you to cut high volume of material in a short time, which is perfect for businesses with plenty of orders. This innovation keeps everything organized and makes it easier to get products ready for customers.

There are many automatic cutting machine options available when you decide to buy one, and it might feel a bit confusing. Most importantly, think about what you want from the machine. What are you going to cut, fabric, paper, or something else? Different machines are more suitable for different materials. For instance, if you like making things with fabric, you should get a machine that can work with different fabrics. Now, consider the size of your machine. If you do not have much room in your workplace, a mini automated laser cutting machine from MINYUE would be perfect for you. If you have plenty of space and want to work with large pieces, a bigger machine would be a good idea.

Another important factor is the cutting speed. Some (machines) cut faster than others. If you are doing a heavy workload, the feature of a quick cutting ability may be your requirement. Also, think about how easy it is to use the machine. Machines that are easier to use will help you make your first steps quicker. Think about features like a touchscreen and straightforward controls. And, last but not least, remember to look at the price. MINYUE manufactures a variety of machines that should fit most budgets, so there is no need to go over your limit.

The purchasing of the automatic cutting machine did cost you a good sum of money, so now the best thing to do is to get the most out of it! The first step is to neatly organize your work area. Make sure that there is enough free space around the cutting machine for it to work not only safely but also effectively. Moreover, having all your necessities within arm's length is quite a practical idea. You will save a lot of time not having to look for what you need while working. Afterwards, train your workers on the proper operation of the MINYUE robotic laser cutting machine. The production is also going to be quicker when everyone is familiar with the machine usage.

Another advice is to maintain your machine regularly. Taking care of it will help it run better and last longer. You can also seek efficiencies in your process. So, if you can cut 3 at once for example - do it! That can save you tons of time. It can also be helpful to use software to plan your cuts. Some machines include software that allows you to program how the materials will be cut, which can save material and time. Lastly, never ignore your production stats. Keep track of how many you can crank out in a given day and look for ways to improve. With some planning and effort, your MINYUE automatic cutting machine can help you to work smarter and more efficiently.

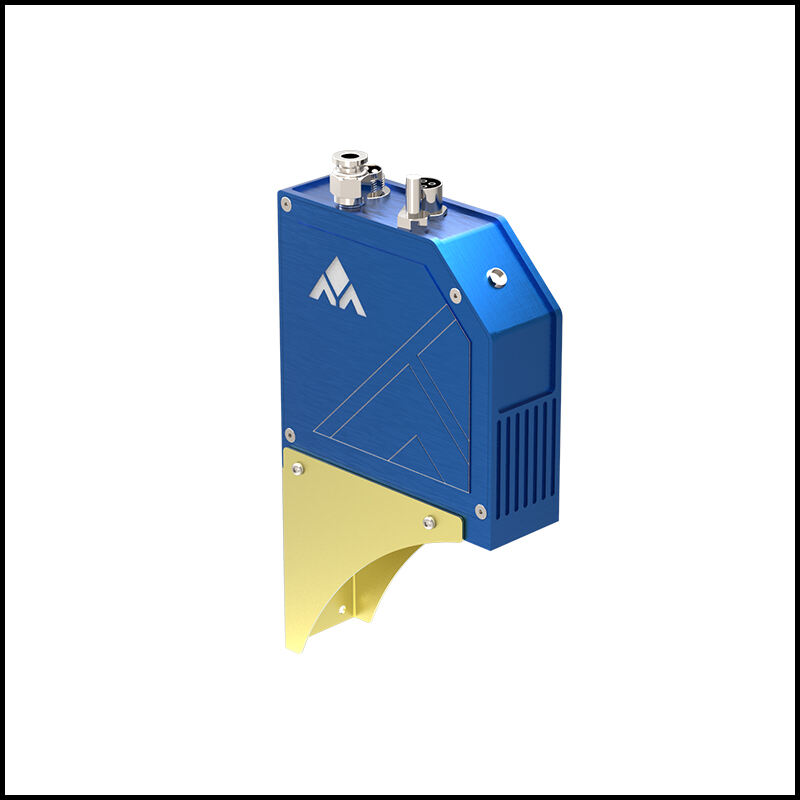

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.