It’s a smart idea to mechanize slicing materials in factories and workshops. It’s as if a robot did the heavy lifting, so whether you’re working with wood, metal or plastic, everyone is left with a sense of accomplishment. What to Cut At MINYUE we specialize in working with high tech machinery that can cut a variety of materials--from metal to textiles. These machines follow precisely programmed measurements, so they can make pieces that fit together perfectly. This enables businesses to save time and money, while ensuring the quality of the products they sell. The automated laser cutting is helping to reconfigure how things are made and enabling companies to stay relevant when customer wants change.

This describes a brand-new technique of reducing product through using devices. Typically, employees depended on a selection of devices — scissors, saws — that frequently reduce at sluggish rates as well as certainly not extremely exactly. Nowadays, machines laser cutters, sprinkle plane cutters as well as CNC (Computer system Numerical Command) devices amongst all of them perform the function. These gadgets are actually computer-controlled as well as can easily comply with designs towards reduce exactly as needed. This is actually an innovation changing production: speeding up manufacturing. For instance, if a furnishings business have to create a a great deal of dining tables, automated reducing can easily quickly churn out all of the items with no mistakes. Workmen can easily focus on various other tasks, as well as the whole manufacturing facility operates much a lot extra efficiently. At MINYUE, we understand exactly how Auto-cutting assists companies expand. It allows business to create brand-brand new items faster as well as be actually much a lot extra receptive towards client requirements

In wholesale production, it is EXTREMELY precise. When you are making many items, every one has to be a perfect fit. A close approximation to this service is automated cutting which employs machinery to cut materials with precision and perfection. For instance, if a clothing brand wants to make multiple shirts, the pieces of fabric must all be the same size and shape. An automated cutting machine can cut hundreds of pieces in the same way, meaning that no matter how many shirts they make, each one will look and fit like another. This continuity is important because it keeps people happy. As designs go, brands aren’t where consumers are looking for surprises. If they find a shirt they like, they want to know the next one will be just as good. At MINYUE, we know how game-changing that kind of cutting accuracy can be for our customers. Because they know they can depend on the quality of what comes out, they are enabled to take larger orders and big projects. Not only does it help businesses grow, but it also fosters trust with their customers. When products are manufactured accurately, it enhances the brand value and brings customers back time and again. When it comes to cutting, automated laser cutting is all about better, faster and more precise.

It can be overwhelming when you’re on the hunt for the best automatic cutting machines for your business. There are so many options, and you want to make sure you’re choosing the correct one. One good place to begin is visiting local suppliers and online retailers that offer cutting machines. A company you may want to look at is MINYUE. They have an extensive line of automated cutting machines to help keep your business running smoothly and efficiently. When searching for cutting tools, consider the materials you'll be working with. Some are good for fabric; others work well with wood, plastic or metal. That will narrow your selections. You should also consider how much you are willing to shell out. When it comes to price tag, you’ll find that automated laser cutting can range quite a lot between the cheap and expensive options out there so it’s important to purchase one that is in your budget, but also fulfils all of your needs. Also, the size of the machine is something to factor in. Some are large and may require significant space; others are smaller and can be packed away in a corner of your workshop. And, of course, be sure to check out reviews from other customers. This can help give you an idea of just how good a machine is and whether it’s worth your investment

If you are wholesale buyer then it is vital to know about cutting technologies that have been automates. These machines will be able to save you a ton of time and money, which is very beneficial for your business. Automated cutting programs can assist with fast and accurate material cuts in this process. This allows you to make more items in a shorter amount of time. It is important to have machines that can manage large volumes as accurately when you are purchasing in bulk. For instance, if you are cutting fabric for clothes, you need accurate cuts so that the clothes fit well. Equipment for the production of such bags are offered by MINYUE, those are intended to work with different materials and sizes which makes this machine perfect for wholesale customers. And one should also think about how they will be trained to use these machines. A lot of automatic cutting machines have a user-friendly interface, but it’s still good to have some training so everyone knows how to use them properly.

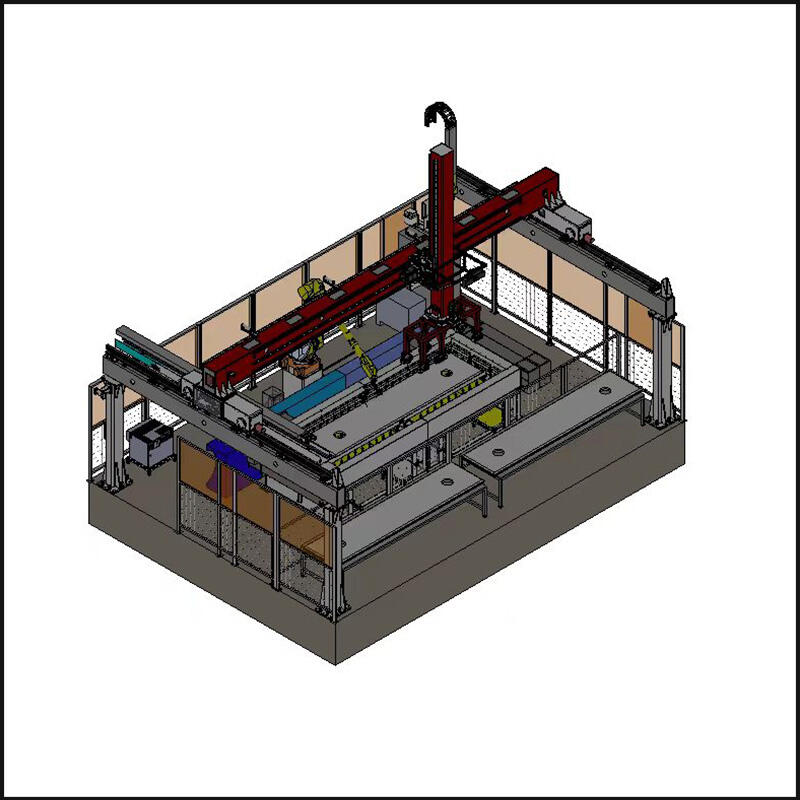

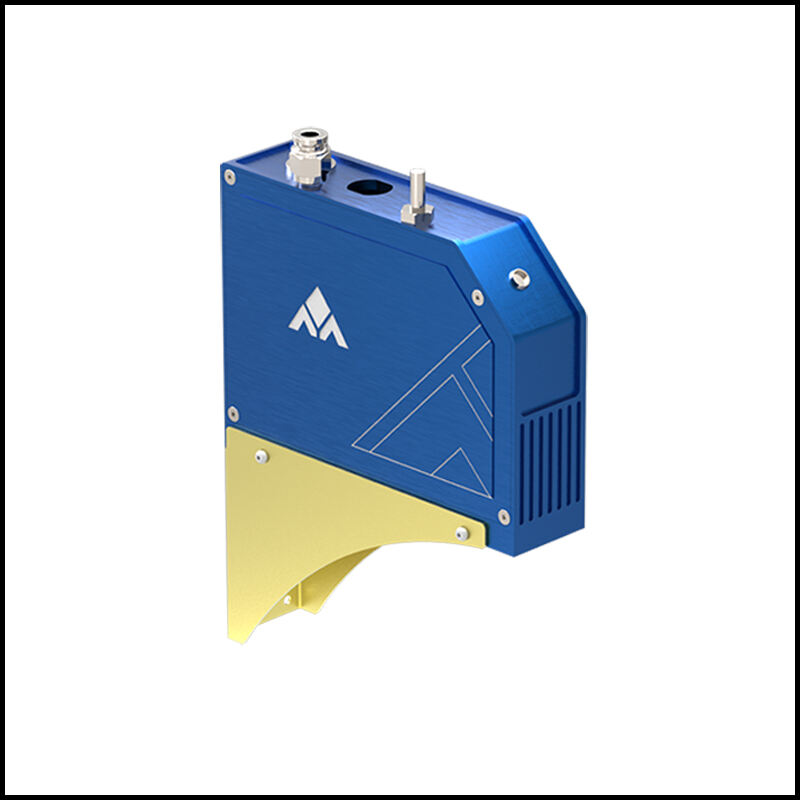

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

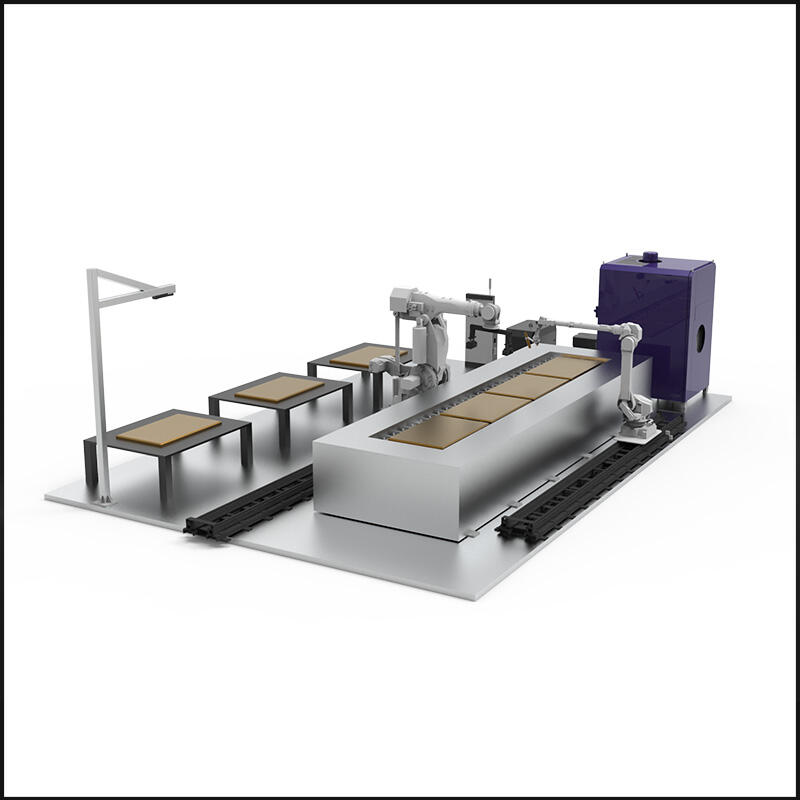

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.