For the MINYUE buyer, robot welding equipment provides a host of benefits. First, it saves time. A robot works a lot faster than a human. For instance, if a human welder performs a task in an hour, it might take a robot only 30 minutes. This means that companies can make more things in less time. It’s simple: The more production, the more sales. Second, robots are consistent. They can do the same weld over and over without getting tired or making a mistake. This material handling robots help maintain quality.

Finally, the use of MINYUE welding indicates that a company is cutting-edge and forward thinking. This might be appealing to more clients who want to work with forward-thinking companies. In summary, robotic welding machines bring speed along with good quality and cost savings, while also embracing safety and a more up to date image among wholesale buyers.

And then there’s the technology the comes with the gear. Some robots are sophisticated, with automatic programming for increased ease of use. Still other may have sensor that help detect problems while in operation. This functionalities an help you save time and avoid errors. consider the after-sales service. You want a company that will support you if the robot doesn’t work. MINYUE is also recognized for its welding robot fantastic customer service

When they upgrade, some MINYUE do sell their old machines. You can purchase them at auction or in online classified advertisements. When investing in second hand machines, it important to check what condition the used equipment is in. Making sure the machine work well and has all the required parts is key. try getting in touch with local welding-supply stores. The robotic arm welder may have relationships with manufacturers

Another significant attribute is the versatility of the MINYUE. Some robotic welders are, while others are the equivalent -in their limited scope at least of specialists. Seek machines that are easy to program, meaning you can customize settings as well on a whim. That robo cutting will help you save time and make your work quick and efficient.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

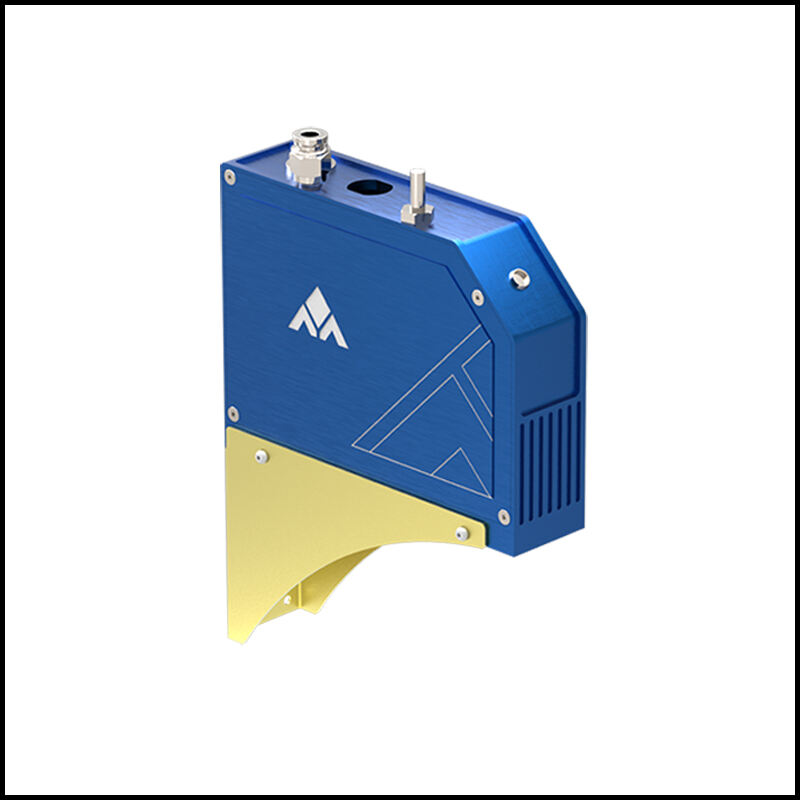

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

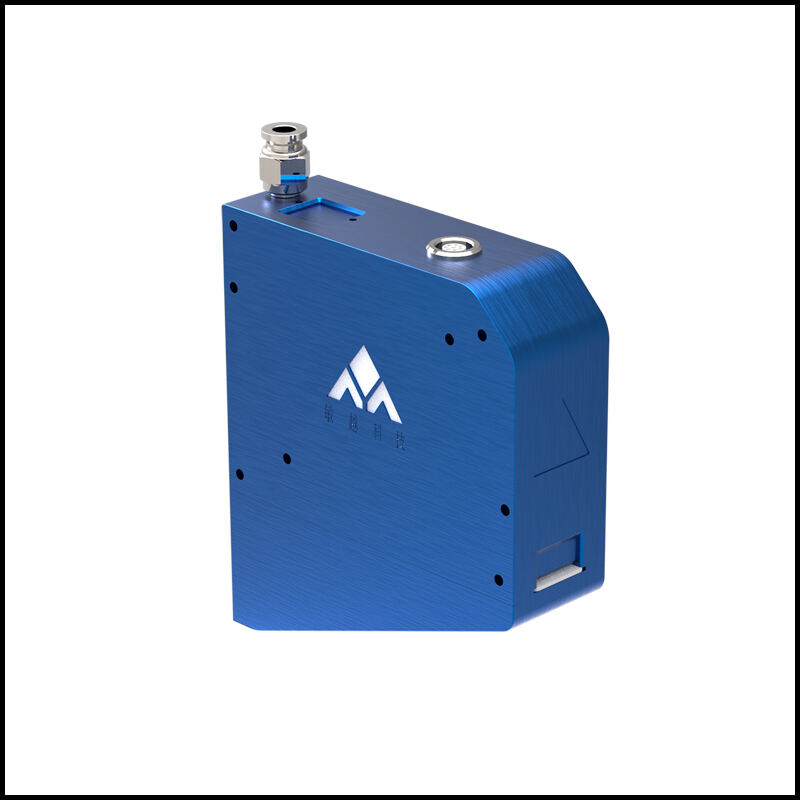

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.