MINYUE's plasma technology is for precise cutting. This means machines can carve out metal with a lot of precision. It helps the computers replace the traditional method in the cutting process such as cutting metals into different shapes or sizes with very few errors. This accuracy is extremely important so we can produce a large number of items in a short time frame, and do so accurately. We save time and materials, so we can better concentrate on producing even more of the products that people want.

Sometimes, if you notice some edges of metal, they can sometimes appear smooth and angled, right? That’s known as beveling, and it puts a nice finish on the edges of metal pieces. These beveled edges can be done easily and faster with MINYUE's automated machines such as robotic laser cutting. These machines operate quickly and make precise cuts through the metal. We are able to do this so efficiently that we are able to produce significantly more parts that we can do otherwise, which is a huge factor when it comes to our production. If we can make more things faster, then we can help more customers.

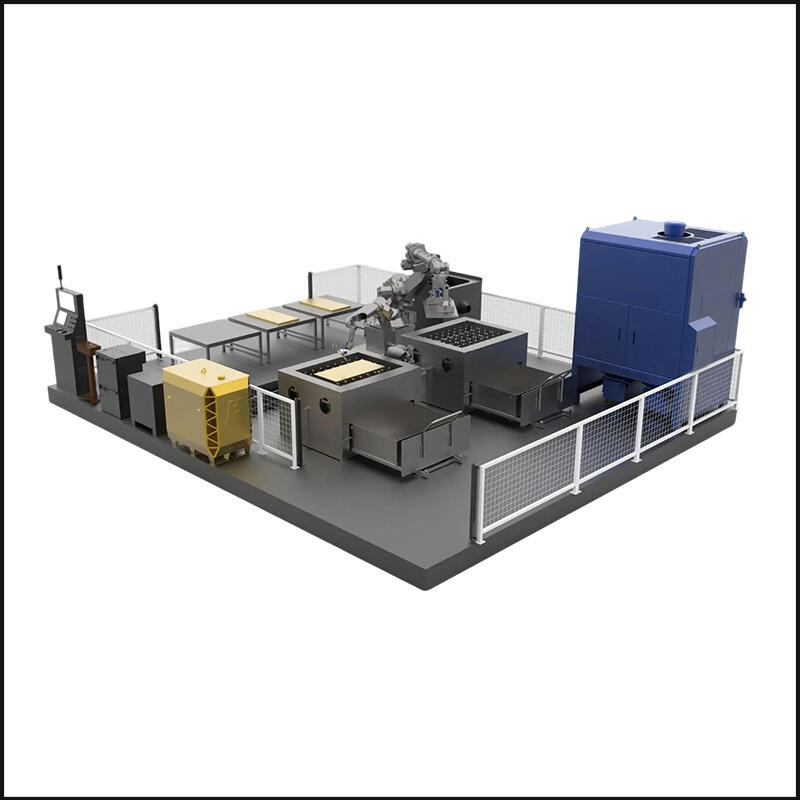

What I love about MINYUE’s plasma technology and intelligent Bevel cutting workstation is that it produces high-quality cuts. This is a step up from older cutting methods that could leave rough edges. And because the machines slice through the metal, it does not leave jagged edges. Thus, our final products not only appear great but are durable and also rigid. High-quality items are essential to customers, and with this technology we provide what customers love.

With the help of MINYUE per automated plasma machines along with automated laser cutting, our productivity has improved a lot. It means we can produce more goods in shorter time. With the machines working fast and correctly, we are able to churn out many products in no time. This is crucial in allowing us to fill orders quicker and more effectively. Fulfilling orders quickly is good for our customers, and that drives our business to grow no end.

MINYUE Plasma technology offers best-in-class capability for cutting and beveling applications. They employ cutting-edge machines that ensure fast and accurate cuts every time. This ensures that our machines are always able to operate effectively, thus helping us in meeting our production targets. We operate when there are reliable machines know no matter how we are not carrying out efficiently.

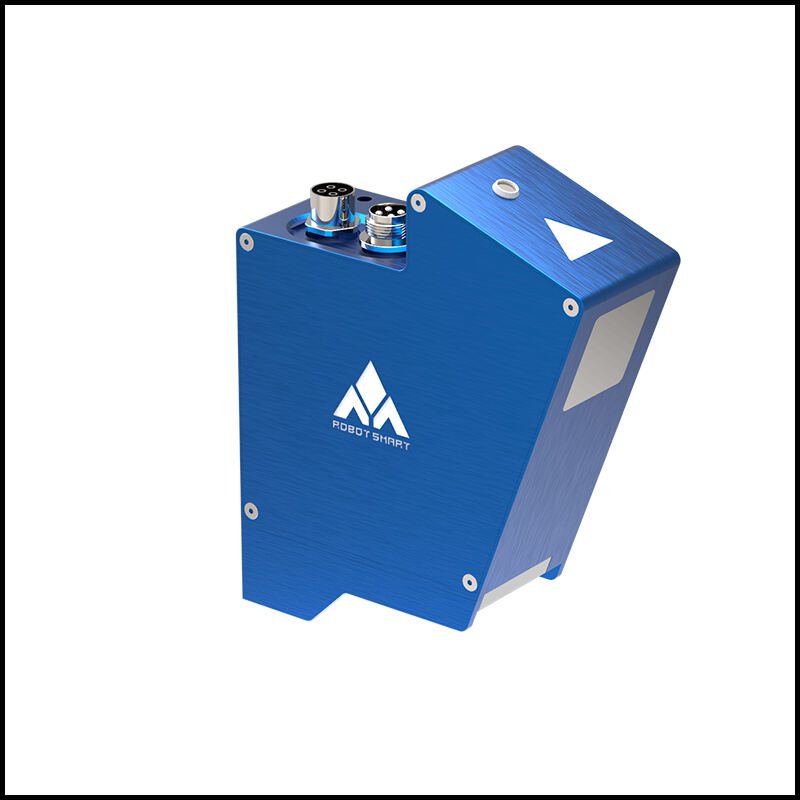

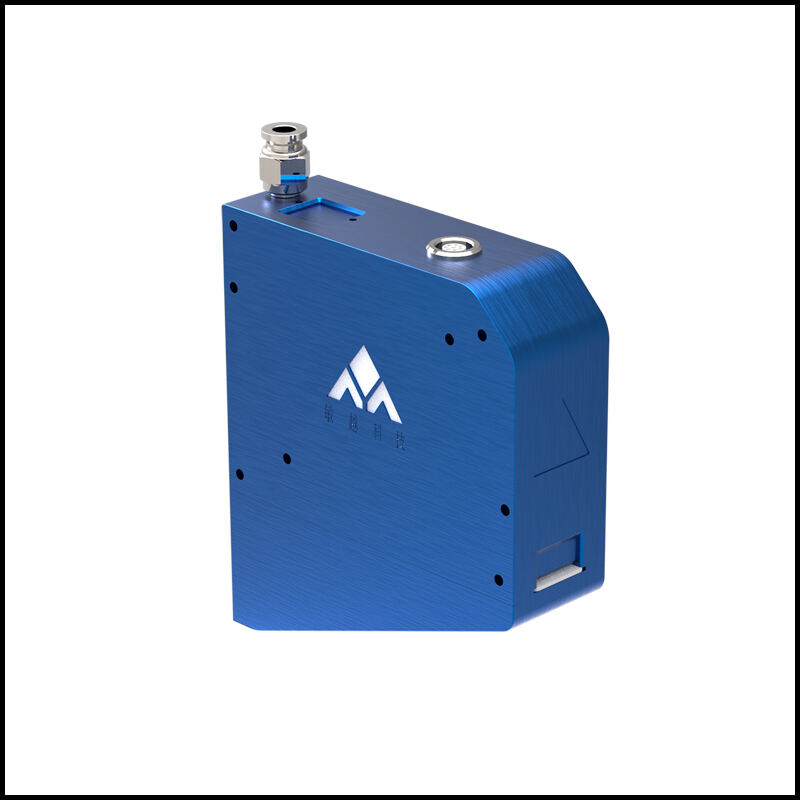

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.