Such angle-cutting machines not only allow the human worker to make angle cuts but need not necessarily be a human worker. These MINYUE cantilever robot intelligent welding workstation help a lot in getting the cuts right. MINYUE also designed a Special-Bevel Cutting Machine for the Precise-Cutting of the material. Let’s explore how this fantastic technology is transforming workshops and aiding operators in more efficient and quicker work.

New technology is constantly improving the capabilities of bevel cutting machines. Smart machines from MINYUE are paving the way for the future of cutting tools. MINYUE Ground rail welding workstation allows workers to make precise cuts at various angles, saving them a great deal of time and positively affecting the accuracy of their work. This machine allows workers to worry less and focus more on doing their jobs correctly. This new technology truly enhances the functioning of workshops and helps them a lot faster, structured, and productive.

MINYUE smart bevel cutting machines redefines traditional workers cutting way on different materials. This sophisticated machine takes the choice of angle from workers. Once they set the angle, the machine will handle the rest of the work for them. This functionality allows plenty of time-saving and minimizes the risk of errors, making cutting faster and more dependable. And, of course, for cutting around other obstacles and surfaces without needing to re-tool or re-setup; they can just turn the device in whatever direction they want to cut at that moment. This allows workers to seamlessly adjust to various projects.

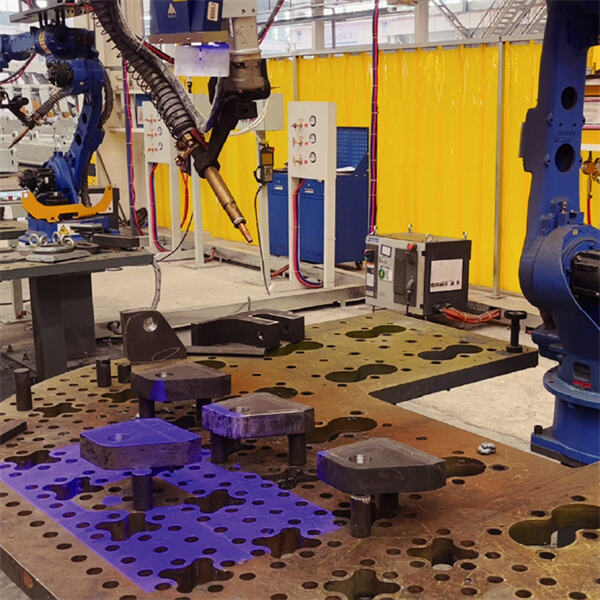

MINYUE Using this technology, workers can do their cutting work much more quickly and without error. The autonomous workstation removes guessing from cutting angles, ensuring that workers make precise cuts every time. This MINYUE 8-axis cantilever robot welding workstation is increasing production and efficiency in workshops and saving time and money for workers in the long run. This means that more work can get done in less time, which is excellent for all parties involved.

For making perfect bevel cuts, MINYUE’s smart machine is the only tool you need. Workers can make accurate cuts without causing a fuss with this advanced technology. It guarantees that each cut is due, minimizing waste and enhancing quality. For workshops looking for results, this MINYUE 9-axis cantilever robot welding workstation makes it flip-flop easy. It allows workers to feel more secure in their cutting, because they know the machine is going to help them make the best cuts that they can possess.

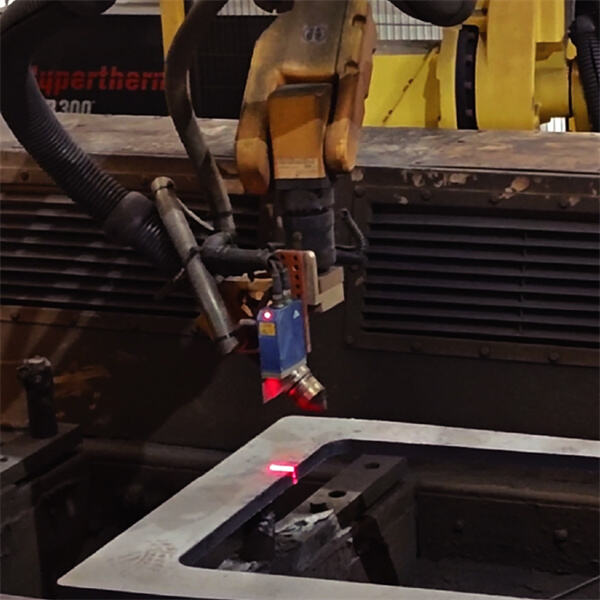

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.