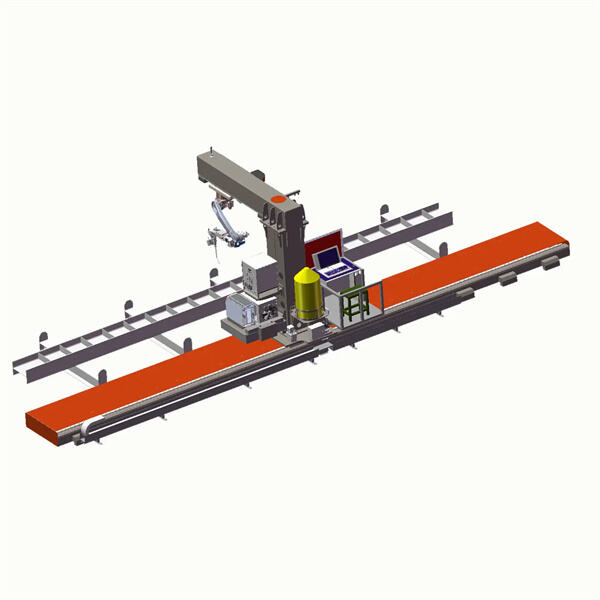

Do you know MINYUE 9-axis cantilever robot welding workstation? This is an extraordinary machine that does welding in its own way. Welding is how you connect two sheets of metal, but this MINYUE Ground rail welding workstation does this job easier and more accurately. So what is this awesome tool and how does it work?

MINYUE 9 Axis Cantilever Robot Welding Equipment (Specialized Welding Equipment) Its nine individual pieces have multiple forms of movement. These components are key as they contribute to ensuring the welding process is right. It features advanced technology, which means it contains several sophisticated pieces of tech that make the welding process easier and more accurate than ever before. It enables welders to perform their jobs more consistently and effectively.

The 9-axis cantilever robot welding workstation is very smart and can do a lot of things. The cooler part is that MINYUE cantilever robot intelligent welding workstation can maneuver and cover different portions of different shapes of weldments regardless of the size. This allows it to adapt to many different types of welding jobs, both simple and complex. Another great thing about it is that it is capable of working on its own, which saves you a good amount of time. This automatic mechanism allows it to accomplish the precise angle every single time to weld a piece, without a human being controlling everything all the time.

This makes welding a tough job due to the ability to reach difficult angles or when working with heavy materials. But with the 9-axis cantilever robot welding workstation, it is greatly simplified. It is able to carry out welding jobs more rapidly and precise, because it can move in diverse manners and hit different angles. It can be done that way because it is faster and more secure for welding and very useful in the welding industry. Strong, precise welds will contribute to making sure that whatever is being built is safe and will last for years to come.

Introduction of MINYUE 9-axis cantilever robot welding workstation: The whole welding process seems to become easier, faster, and more reliable for everybody involved, thanks to its advanced technology and precise movements. This MINYUE 8-axis cantilever robot welding workstation not only helps welders do their job more efficiently, but it makes for stronger, higher quality welds. Consequently, firms are able to create better products, and that’s good for both employees and consumers.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.