For example, welding joint tracking sensors are effective industrial automation devices that help workers maintain proper welding alignment. In big factories, these sensors have a very crucial role to play, as many different products are produced on a daily basis. Take a closer look and discover more about these useful devices.

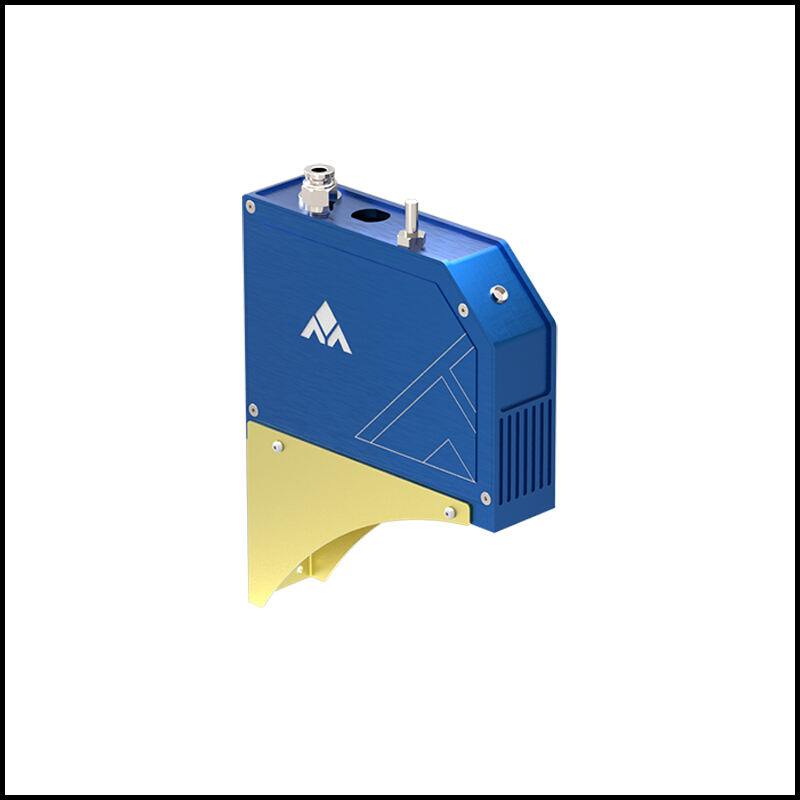

MINYUE welding joint tracking sensors as well as laser seam tracking sensor can be visualized as small assistants that stand aside and ensure the workpieces remain in place while welding. They [smart tools] monitor where the pieces are, and help workers know if everything is going smoothly, using high-tech machine learning. It is like having a Friend who stands next to you when you are working, telling you if you are wrong, or not.

Using MINYUE welding joint tracking sensors and line tracking sensor in factories has many advantages. One big benefit is that this latter type of sensors helps workers double-check that they are assembling things correctly, which saves time and money in the long term. Properly connecting things minimizes the potential for redoing work, which can be very expensive. These sensors also ensure that the welded object is safe and strong. This is especially critical in areas where the end products must be robust and reliable like in construction or heavy manufacturing machinery.

Welding joint tracking sensors as well as MINYUE automatic weld tracking sensor help people work faster and more accurately. They ensure that the pieces being welded are in the right position throughout the welding process. This allows workers to get their work done faster since they do not have to worry about the pieces moving or sliding around. In addition, these sensors ensure the welds are properly located and shaped. This is essential as it confirms that the end product is powerful and secure for usage. Example: Proper welds hold them together in the right way, which prevents possible accidents or failures from occurring later on.

Error detection in factories: Use of welding joint tracking sensors and seam tracking sensors. These sensors are very important in ensuring that products that are being manufactured are perfect and safe for humans. They help identify errors sooner rather than later when they could develop into more serious issues saving time and money. When workers can identify problems early on, they can resolve them quickly. Companies can guarantee the highest quality of their products and that they are ready for sale to customers using these sensors.

In the future, welding joint tracking sensors will still advance and be more and more valuable to both workers and factories. Now, they are in the process of developing new sensors that will be able to do a lot more, including faster and better than before. This means that workers will be able to do their jobs even better, and will have a higher probability of ensuring that everything they create is perfect. We are very hopeful for the future of the new welding joint tracking sensors and can't wait to see what else they come with.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

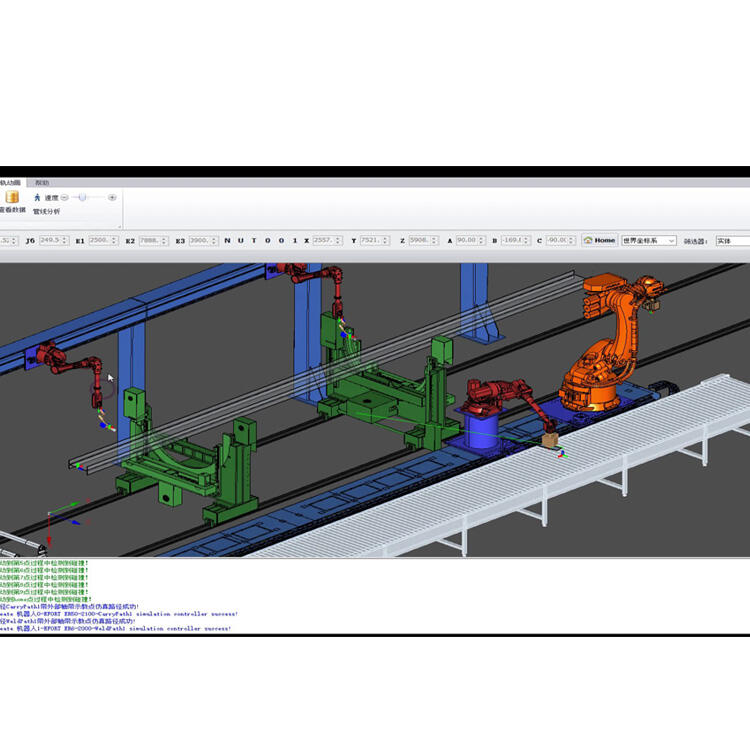

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.