The accuracy is crucial in welding. Welders need to ensure the pieces they are joining fit precisely. This tight interlock allows for a specific interdiffusion of the two materials to make a robust interfacial bond. If the pieces are not aligned well, the weld may not be stronger enough, and it can cause issues later. This is where MINYUE's small seam tracking sensor as well as laser seam tracking sensor comes to solve. This handy tool tracks the seam during welding using smart technology. It ensures that each welding lays up correctly and smoothly, which is of utmost important for quality work.

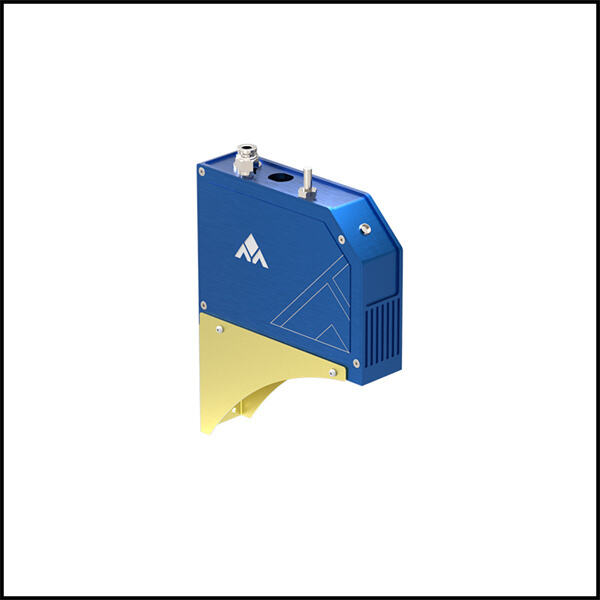

Welding is a tough profession, especially in confined spaces. At times welders have to work in very tight and restricted areas. Which makes it challenging to use larger tools or equipment. MINYUE provides a small seam tracking sensor and line tracking sensor, which comes with a smart design that eliminates the fear of using it in those tight spaces. Its lightweight design enables welders to shift it around without having difficulties performing their tasks. They can go places that may be difficult to access with larger tools. Now, they can complete their tasks faster and more efficiently, even in poor conditions.

Welding is believed to be one of the most critical tasks that need to be done to ensure that the weld seam is strong and secure. A strong weld is required to assure that the final result will serve it is purpose and last. The small seam tracking sensor of MINYUE assists to keep an eye on weld seams effectively. It can detect any issues instantly, enabling welders to identify troublesome areas before turning into larger problems. This allows them to make rapid changes or adjustments, resulting in an ideal weld every time. The use of this sensor gives welders additional confidence that their work will be quality and dependable.

Welding it is very essential to ensure that all the qualities of good welding are met. Quality control of the welding process helps ensure that everything being done falls within acceptable limits. Every weld is made to top quality with the small seam tracking sensor also the automatic weld tracking sensor from MINYUE for welders. It is a very simple and easy-to-use sensor that provides precise feedback on the welding process. It expedites small quality control checks and enables faster work. Quality welders create better work — and they can do so more efficiently, with the right tools in hand.

The small seam tracking sensor of MINYUE intelligently search for seams during welding. This technology is very refined to guarantee optimal placement of every weld. This is so welders would be able to forge strong and lasting connections between the components. This is vital because the right weld can change how well the end product works. Thanks to MINYUE's small seam tracking sensor and seam tracking sensors, welders never have to worry about precise seams. They know they can take care of the job they have at hand because they have the tools to help them.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.