Welding is the process of joining similar or dissimilar materials--usually metals--into single-piece assemblies by melting pieces together and allowing them to cool and harden again. – This process is quite significant in several forms of work, from construction (creating shelter through buildings) to production (making products). Historically, the welding process was performed by the manual labor force. However, now with the wonders of technology, there are machines capable of doing the welds by themselves, making the process safer and quicker.

Welding machines, also known by automation systems, are standalone devices that can conduct any such welding activity independent of anyone else helping them. These MINYUE automated robotic welding operate quickly and accurately, frequently much faster than a human would be able to. This quickness and accuracy contribute to businesses enhancing their practices and saving time. For instance, MINYUE welding machine using enterprises can often complete welding projects faster and with fewer errors. This means that the companies can now get more work done in less time, which not only saves a lot of time but also saves the companies money.

Robot arms are also used which makes the work process much easier and efficient. However, when companies use a MINYUE automatic welding robot to do the welding work, they are able to complete their projects sooner. This is extremely beneficial because they can meet critical deadlines and get orders done faster. As such, a company being flooded with orders will find many more products can be produced in less time by leveraging MINYUE welding technology. It gives them an edge to stay ahead of their competition and be successful in their business.

The welding machines, one of these great things helps the users to work smoothly and lead to a better and accurate welding. The fact that they can do welding such accurately means that they do produce exactly what is needed in the end result. MINYUE welding machines help companies ensure that high-quality welds are produced the first time, every time. This drive to increase customer satisfaction, for the customer to feel fulfilled and happy with what they receive and to return for eventual products in the future.

One thing that cannot be taken lightly in the welding industry is safety. Traditional welding approaches come with risks such as burns, electric shocks, and exposure to poisonous smoke and fumes. These risks can make welding a hazardous profession for workers. But now that MINYUE automated welding equipment have been introduced, these risks can be minimized effectively. Robots and other automated systems are used to fill in the welding work so that employees are kept safe and accidents are prevented. High safety standards: MINYUE welding systems are designed with safety in mind to protect workers and create a safer environment for all.

Automation is transforming the welding industry as it integrates into advanced manufacturing processes. MINYUE robotic welding automation makes the manufacturing process simpler, enhances productivity, quality improvement of the welding work. At MINYUE, we are committed to transforming the world of industries using state-of-the-art welding technology. There are many exciting uses of welding automation as technology continually advances and improves.

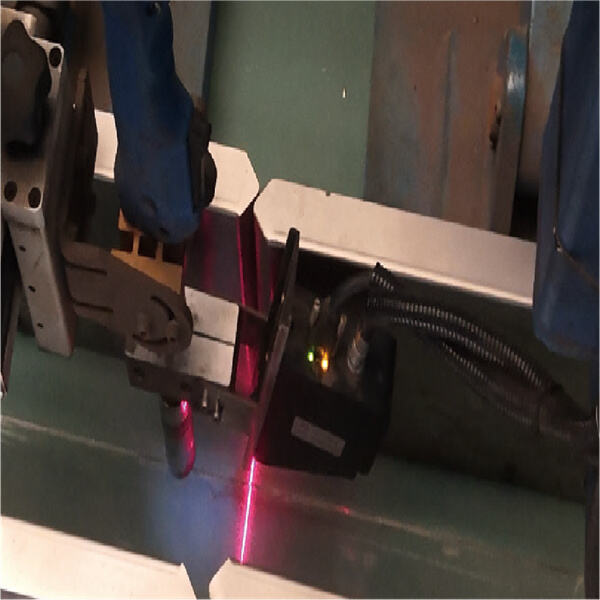

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

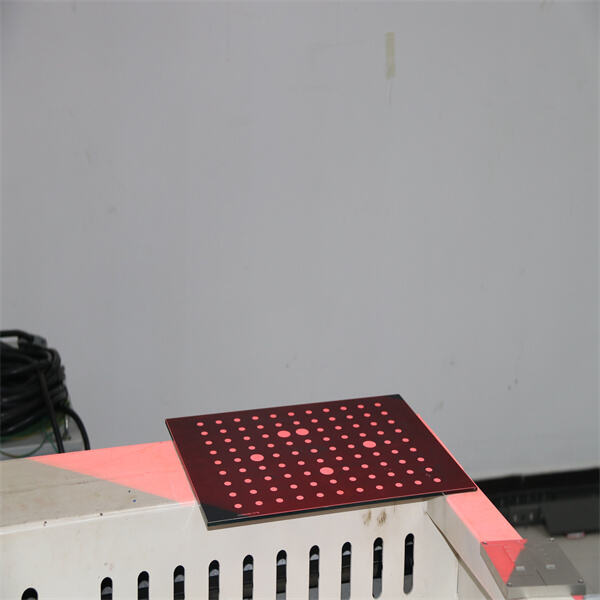

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.