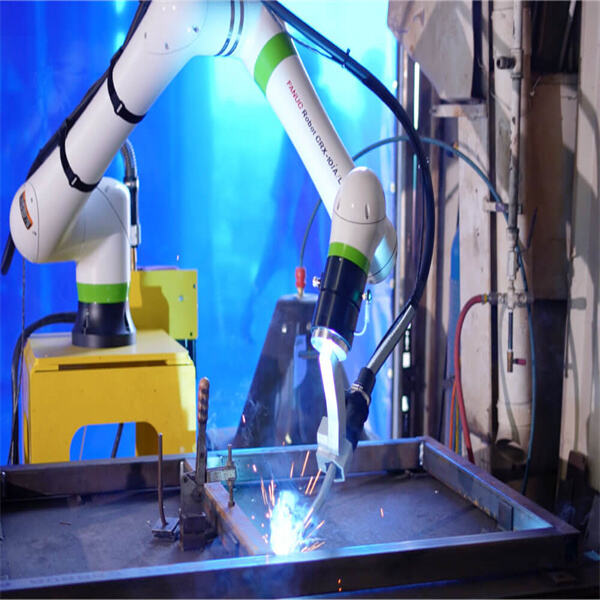

Robotic MIG welding is revolutionizing the way we produce our goods. Already, new tools can make welding jobs more precise and faster, including with the help of laser vision systems. This results in higher-value products in less time. Enterprises such as MINYUE take the lead with these sound systems. They aid factories that produce many different types of products simultaneously, a practice known as high-mix production. Laser vision systems enable lasers to “see” and examine where the weld should be placed. This technology ensures that the welding robot really knows what he’s doing. No more guessing or mistakes!

Why is Robotic MIG Welding Gaining Attention?

There are advantages in applying laser vision systems for robotic MIG welding. First, they increase accuracy. Lasers can locate the precise place to weld, which minimizes errors. When the welds are correctly made, its end product is improved. This is particularly significant for companies like MINYUE, which accuracy is crucial. Better quality equates to happier customers, and that potentially could lead to more business.

Another good thing is speed. The welding robots are able to work faster with the help of laser vision systems. They soon dash and round about the surfaces which are to be welded, making pace as required. That means the robots are spending more time welding and less time figuring things out. Fast factories can fill orders and make money.

These systems also reduce waste. Accurate welding means you throw away far less material. It saves money and is good for the environment. In a world where we reach out to sustainability on the top shelf, using less material is one of the ways companies can show they give a flying fa doodle about the planet, she said.

Finally, the workers work becomes easier through utilization of laser vision systems. And workers don’t have to correct as many mistakes. Instead, they can concentrate on higher priority tasks, such as planning the next steps or overseeing other parts of the manufacturing process.

The Best Way to Use Laser Vision Systems for Maximum MIG Welding Productivity

Understanding where to deploy laser vision systems matters in the quest for maximum benefit. MINYUE suggestion such system use in those place with various kinds of made item. In a factory that makes car parts or kitchen appliances, for example, the welding systems usually have to adjust to varying shapes and sizes. Here’s where laser vision comes in.

Another crucial place is when you’re introducing new jobs. Laser vision systems can also be employed to find the optimum settings for your welding robot when you are first starting a project. That way it doesn't end up guessing, trying to figure out what to do. Instead, it employs the laser in order to measure with precision. This is super helpful in high-mix production situations where the same machine may be used to make many different parts.

Where the laser vision system is located also does matter. It has to be able to see what it’s welding, including the work material and the weld area. When it is blocked, it can’t work properly. Companies also must ensure the cameras and lasers are properly positioned for optimal performance.

Continuous monitoring of laser systems is also important. When production run changes, the laser settings should change as well. Staying abreast of new techniques and technologies makes a world of difference. MINYUE can assist companies in adjusting their systems to a changing environment.

Knowing where to apply these systems, businesses can make the most of them. Good equipment and proper setup get better results and quality if that's what you need. That's important in a competitive market today where consumer expectations are relentless.

Which Laser Vision System is Right for Your Welding?

If you are searching for a laser vision system welding, there are some factors that you need to consider. First, consider what you will be welding. The type of system depends on the material, metal or aluminum may require a different type. You will want to choose a machine vision solutions that is compatible for use with the materials you use most often. After that, factor in the size and shape of what you are welding. There are those that work best for small parts, and others that manage larger pieces. Take a close look to ensure the system you select can accommodate your specific production requirements.

Also, it depends on how accurate you need to be with your welding job. If you require extremely accurate welds, you'll need a high-precision laser vision system. At MINYUE, we can assist you to choose the right accuracy level as per your welding projects. It’s also a good question to ask about the speed of the system. And in high-mix production, tear-down and set-up time can be saved if you can switch over quickly from one task to another. Opt for laser vision systems capable of quickly re-configuring to new tasks and which don’t impede production speed.

Finally, what about customer support and training. A system from a company such as MINYUE provides you with the expertise to call on if something goes wrong. Great support should be able to teach you how to make it all work, so that your welding is as hassle-free as possible. So while you are in the search for the best laser vision system, remember to think about materials, size, precision, speed and support that will help you succeed.

Why Invest in Advanced Laser Vision Technology?

There are many reasons why you should consider investing in the latest technology for laser vision welding. One of the main reasons this technology has been chosen is because it improves the quality of welds. When welds are done right, that’s less rework and that can save time and a lot of money. For instance, if a weld is poorly done, it may have to be redone, resulting in wasted materials and hours of extra labor. Because it uses a laser vision system, MINYUE can accurately position welding joints right where they belong and minimize error for better quality.

It also speeds up the production process. Use modern laser vision technology to rapidly scan the parts and direct the weld. That translates to faster, smoother production lines an imperative in high-mix applications in which you need to make many different parts. Having the ability to produce more products in less time increases these companies’ efficiency and bottom line.

Moreover, such technologies commonly come with 'smart' functions that assist operators in monitoring their operation. This might enable more effective oversight of operations and catch problems earlier. With MINYUE systems, companies not only follow the lead of IT technology development closely, but they are ensured to enhance their future growth potential. Eventually, these advanced processes keep better results, which in return ensure the trust and satisfaction of the client.

Where Laser Vision Systems Can Enhance and Improve Welding Quality and Efficiency

Laser vision welding systems can offer a great boost to the quality and efficiency of welds in some specific points. And one location where the technology really stands out is in high-mix production. These are places where many different products are produced on a regular basis. With 3D laser vision sensor systems, employees can change to a different weld type without any time lag. This kind of flexibility is what has enabled enterprises such as MINYUE to maximise output and stay competitive.

Another potential for improving the process is to obviate or improve quality checks during welding. Conventional welding systems might use a human to inspect the weld while it is being made. This may not be an issue but can result in errors if the operator is fatigued or distracted. Laser vision systems, on the other hand, are capable of maintaining surveillance of the welds in real time. They can even offer real-time feedback to course correct if necessary. This guarantees that each and every weld is as perfect as can be, resulting in stronger, more precise products.

In addition, laser vision systems can help in the training of new staff. New workers can also learn faster working with advanced technology as the system guides them in real-time. This minimizes errors and assists in better comprehending of the welding process. MINYUE systems can also decrease scrap material, which is additional parts that get thrown away because they are not good enough. And with laser vision, businesses can increase quality and efficiency, reduce waste and save money when creating stronger products.

Table of Contents

- Why is Robotic MIG Welding Gaining Attention?

- The Best Way to Use Laser Vision Systems for Maximum MIG Welding Productivity

- Which Laser Vision System is Right for Your Welding?

- Why Invest in Advanced Laser Vision Technology?

- Where Laser Vision Systems Can Enhance and Improve Welding Quality and Efficiency

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK