Wholesale buyers can gain numerous benefits from utilizing welding robots. For one thing, these robots can work around the clock with no breaks. They don’t fatigue the way we do. In other words, companies can make more items in less amount of time. For instance, while it might take a person hours to weld together 10 metal parts, if a factory has to construct 1,000 of them, the welding robot could be programmed to do so much more quickly. Also, robots are very precise. They can ensure that every weld is strong and tidy. This will reduce errors and save money. A weld done incorrectly might lead to trouble later on.” Robots are much less likely to make errors

Welding robotics have actually another point opting for all of them, as well: They can easily operate in harmful atmospheres. Manufacturing facilities include warm, hefty products. Robotics can easily deal with these products they will not end up being sick. This maintains individual employees risk-free. Security is actually essential at any type of location of function. When individuals feeling protect, they are actually much a lot better capable to perform their tasks. And after that there is the bucks as well as cents: utilizing robotics can easily assist business conserve cash. While the preliminary expense of purchasing a robot could be higher, it may really conserve cash over time. Robotics can possibly do the function of lots of employees sometimes, as well as they might decrease the dangers of mishaps also.

PhotoWelding robots are incredible machines that help factories make sturdy things. But, like any machine, they require good care for peak performance. As a buyer who is also interested in utilizing welding robot, then it’s essential to first know how to maintain their good state. Regular maintenance is key. That is, lots of time spent monitoring the robot for issues. For instance, you need to be examining the welding tips, cables and the robot’s arms. If one looks worn or wrong, it needs to be repaired or replaced immediately. Small problems can become big ones when they are ignored and it usually costs more to solve

You might also try local distributors. They can assist you to locate the perfect welding robot that will offer you years of quality work at a price you can afford. Do ask about the robot’s capabilities, and any potential additional costs (like maintenance or parts); don’t shy away from asking questions. Finally, consider financing options. Some firms sell payment plans, which could help you afford to buy a welding robot. Learn how you can afford the ideal welding robot for your factory with some research and preparation

Robots are the future of welding! Many new inventions are helping these robots do their jobs better. Among the coolest advancements is the application of artificial intelligence (AI). How AI is teaching welding robots to improve their skills. That means they can practice welding on their own. For instance, when a robot makes an error, A.I. can teach it how to comprehend what happened and adjust its behavior in the future. This AI welding robot allow for faster and more precise welding. MINYUE is the leader in these advancements, offering robots employing Al to perform better.

Another promising advance is the evolution of improved sensors. These are the sensors which allow industrial welding robot to see more clearly what they are working on. They determine whether the metal surfaces are clean and suitable for welding. If something is amiss, the robot can stop and call the workers over. This contributes to error avoidance and the production of high-quality welds. Some robots can even configure their welding speed and power in response to what the material they are working with needs

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

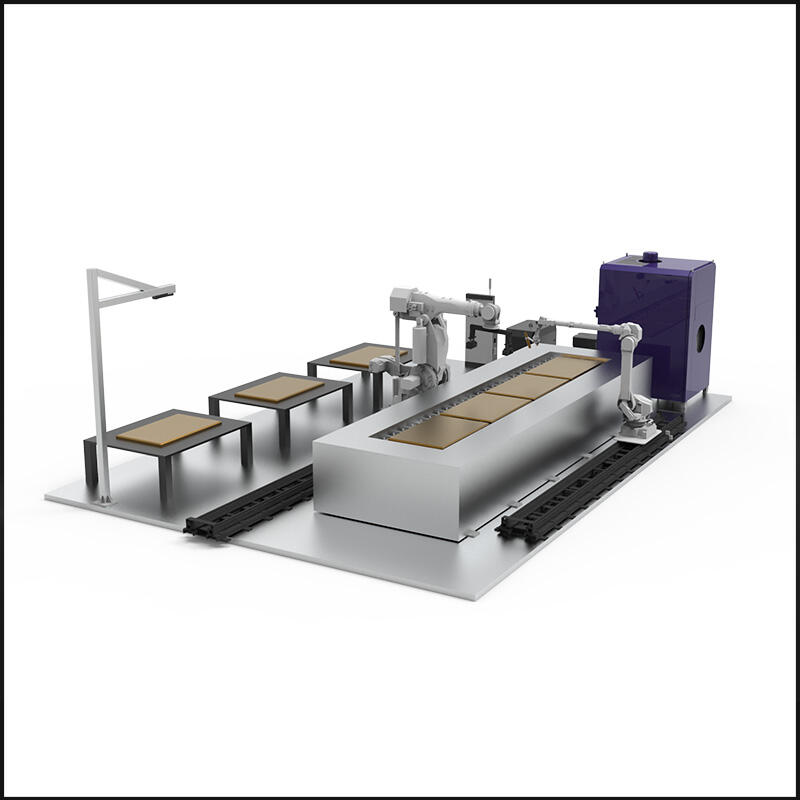

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.