A robot is a machine that can perform tasks independently. MINYUE welding robot are more useful in various forms of work and help people do things easier and quicker. In this video, we will discuss about AI welding robots. These robots are special because they can think and learn, just like people. Now, let’s delve into how AI-based welding robots are transforming factories and manufacturing!

Automated welding robots in the manufacturing industry are highly precise. What this means is that they are able to perform a certain task in exactly the same manner every time they do it. This is very vital in welding since even a tiny human error may lead to a lot of issues. We know that every weld is flawless when working with an AI welding robot on a project, guaranteeing that everything we construct is sturdy and dependable.

One of the key advantages is the robots for AI welding is the higher speed. Their processing speed is far faster than that of a human. This rapidity of time allows things to be manufactured more quickly, which is a particularly beneficial attribute in factories that produce a lot of merchandise in a short amount of time. By using AI welding robots, organizations can create a higher volume of contents in a shortened time frame, allowing them to fulfill more client requests.

A new technology in the world of welding industry: It is streamlining the entire process, making it quicker and more accurate. Welding in the past required a great deal of skill and training, and the learning curve could take quite a while. However, due to the emergence of AI welding robots, even a novice can produce seamless welds. This explosion of activity is making welding accessible to more people, opening up this crucial work to others.

That Finish in the Welding Industry Is All About AI Robots: They're leading the way for the future of manufacturing and revolutionizing factories' operations. MINYUE automatic welding robot accuracy and high-speed operation make AI welding robots the need of the hour in various factories. Minyue has an eye on efficiency, while also staying at the forefront to push this technology forward and inspire the industry and others to adopt as well.

AI welding robots have the major benefit of working continuously. Unlike humans they do not become tired and they do not make errors. This capability of working 24/7 helps the organizations to manufacture more products in less time. Moreover, MINYUE automated welding robot are precise, thus ensuring perfection in each weld, resulting in higher-quality products overall. This is crucial for businesses that want to provide their clients with the best products.

Welding Is Improving through AI Technology It is enhancing weld quality and speeding up to streamline the whole process. MINYUE industrial welding robot has allowed companies to make products faster and with higher precision. This applies particularly well in fields where accuracy is crucial, for example, in the construction or production. By ensuring that the products being made were not just good, but safe for all, AI welding robots are creating an innovative standard for quality in the factory.

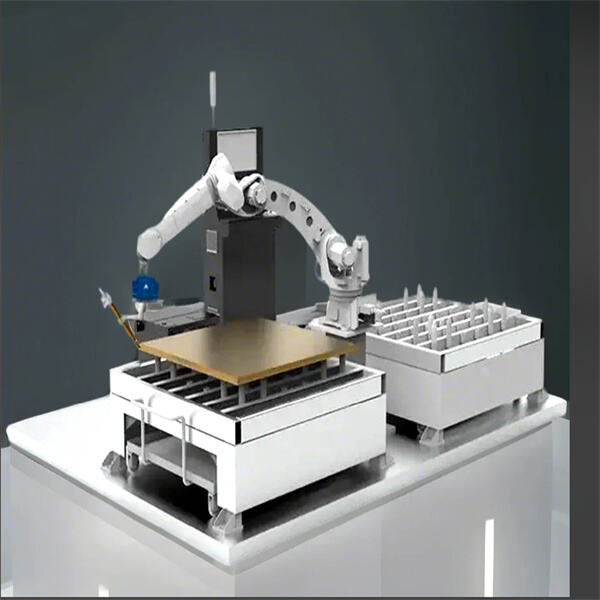

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.