Optical laser sensors are cool tools that allow us to understand more about the environment around us. MINYUE laser optical sensor use special laser-beamed sensors to determine things such as distance, speed, and in some cases, color. This article discusses optical laser sensors, their utility, working, applications, improvements through time, etc. So let's explore this amazing subject together!

Laser Sensors — specialized devices on the principle of laser are used for detecting changes in the environment. You can think of them as little detectives that can identify things that we can’t see. The way these sensors work is they send a laser beam—the focused line of light—and then observe how that beam interacts with everything in its path. As soon as the laser beam falls on an object, it comes back to the sensor. Optical laser sensors measure distance, and speed with great precision can be calculated by sending laser beams toward a reflectable surface and recording the time it takes for the beam to bounce back.

This makes optical laser sensors very rewarding and valuable in many cases. One major advantage is their accuracy. That's how scientists, engineers, and other professionals can be able to know things with super precise degree of existing: Optical laser sensors can make their measurement with accurately. They are also extremely fast and can offer real-time data, which allows individuals to make rapid decisions when time is of the essence. Since optical laser sensors are non-contact, they do not need to touch the items they measure. That means they can get readings from a safe distance, which is particularly great for delicate or hard-to-reach areas that would be dangerous to approach closely.

Optical laser sensors emit a laser beam and then measure its interaction with the surrounding environment. When it strikes an object hit, it bounces back and returns to the sensor. A telescope sends the light a certain distance away and, by measuring how long it takes the beam to return, the sensor can determine how far away the surface is. This technique is known as time-of-flight measurement. Not only do laser sensors measure distance, but they can also use the unique characteristics of the laser reflection to determine speed, color, and much more. It means MINYUE laser proximity sensor are incredibly versatile and can be used in a variety of ways.

The versatility of optical laser sensors can be seen by their many applications in different industries. For example, in robotics, they are frequently used as optical laser sensors to help drones and AGVs navigate through obstacles. This is critical for enabling the safe and efficient movement of robots. They can also be found in manufacturing setting, where they can be used to measure the dimensions of products with high precision, making sure that everything is manufactured correctly. MINYUE laser sensor for distance measurement used in driving assistance systems and collision avoidance systems in the automotive industry work together by making driving safer. Optical laser sensors are also used in environmental monitoring, measuring factors such as air quality and pollution levels, and helping to look after the planet.

Optical laser sensor technology has come a long way and has drastically improved over the years. Technological advances in lasers have shrunk, simplified and lowered the cost of these sensors. This has paved the way for other applications working with optical laser sensors, sparking interest in new areas such as healthcare, farming, and security.

Applications: Smart sensors are applied in numerous fields such as agriculture (tracking growth and development of crops), home automation, healthcare (monitoring patient health), etc. We have many inventions in MINYUE high speed laser sensor technology yet to see in the future, which will have much more useful features of these devices in our day to day life.

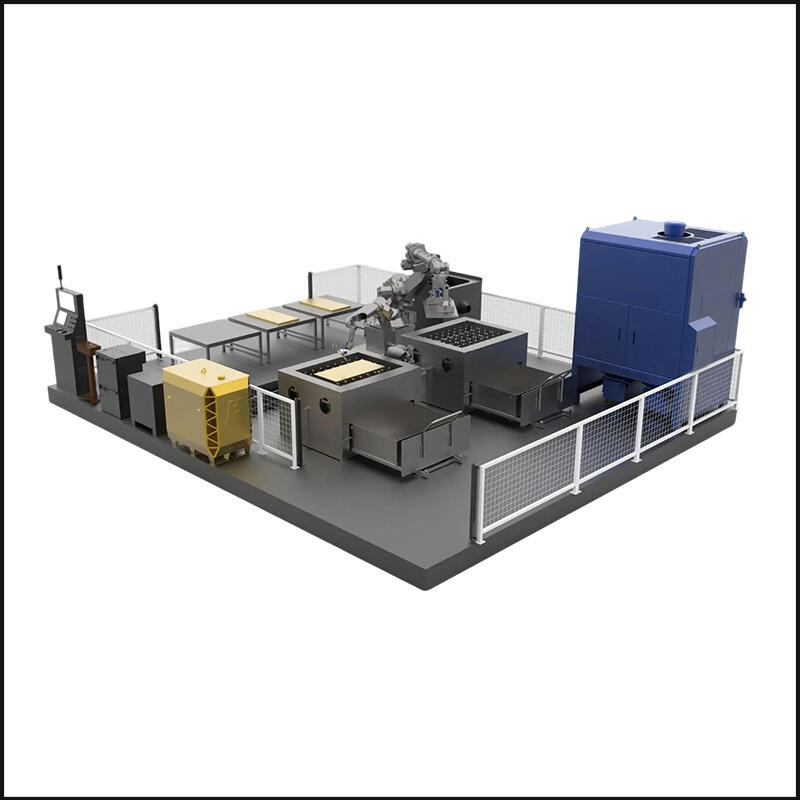

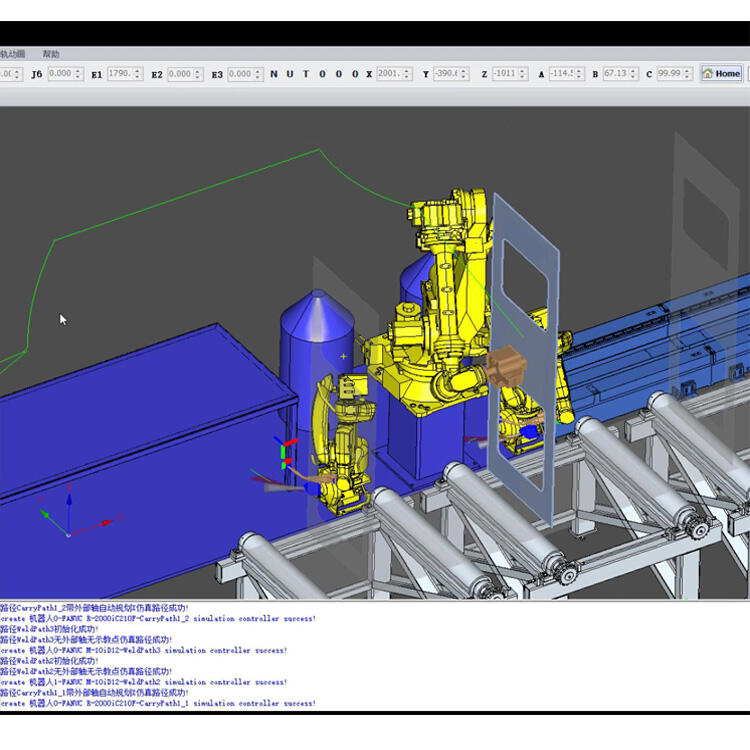

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

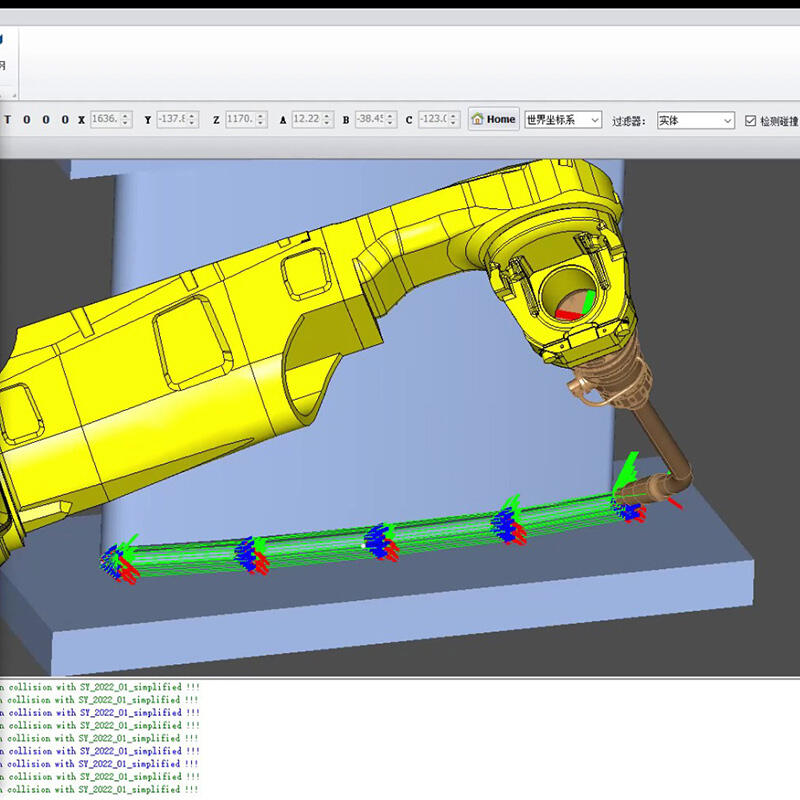

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.