Factories make things, such as toys, clothes and cars. Back in the old days, it took a long time to make these goods because people had to do a lot of the work by their own hands. People labored and spent hours producing few things. However, and in comes the smart machines, everything turns around!

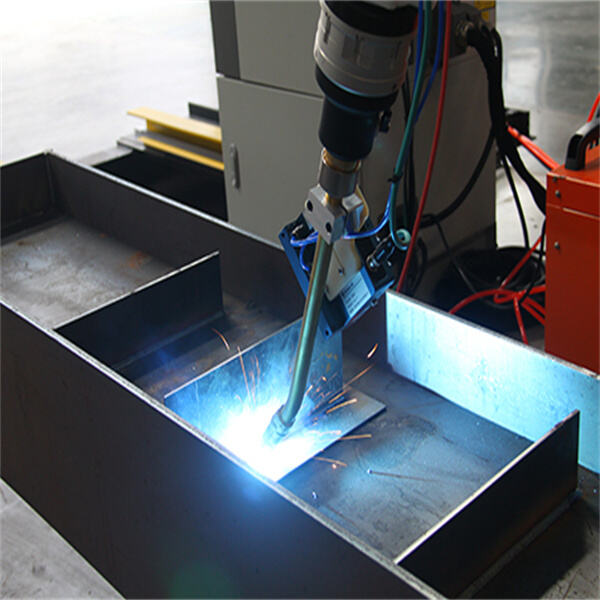

These smart machines (popularly referred to as industrial automation) can perform a lot of tasks faster than you can, and with minimal errors. MINYUE robotic welding automation work vastly quicker than people do and don’t get fatigued, which is a huge assist. This means factories can make things faster and better than ever before.

This way, people can spend their time doing the other important things, since many of these machines are doing the jobs. They can make sure the machines are in proper working condition or come up with new concepts and build a better product. It means the factories can produce products in lesser time which is best for all of them.

Computer programming is another significant aspect of smart machines. This is similar to teaching machines the language they can sense. When programmed correctly, machines like these can do phenomenal things — from moving parts to single-handedly assembling products!

Factories can accomplish this through the use of robots rather than people picking up heavy boxes and moving them from A to B. This is robots designed specifically for picking and moving things around that never get tired. They can work around the clock and organize everything. MINYUE laser welding automation will help make the overall process a lot quicker and safer for all of those involved.

Robotics is a branch of technology that deals with the design, construction, operation, and application of robots. A MINYUE rpa robotic process automation is a kind of machine that can go places and do tasks on its own. They are really big part of industrial automation, and have revolutionized the way stuff is built on factories.

MINYUE is a company that specializes in improving factories through robotic technology. Through the use of cutting-edge robotic technology, MINYUE is able to streamline and optimize its factories. MINYUE robotic process automation has allowed the company to grow and created countless high-tech jobs for those who wish to work in a high-tech environment.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.