We consider ourselves lucky enough to bring new innovations and ideas to MINYUE to revolutionise our daily tasks. This is why we’ve made some unique robotic welding tools that allow the work to be faster and better for everybody. These are tools to help workers and companies create good work with fewer hands on deck.

The automated robotic welding is basically machines do the welding instead of humans. This skill is extremely precise, it can do the job much better than human hands. Our robots are trained to ensure every weld is perfect every time. Not only does this save much of time, but it also assists in producing far better quality products. The more accurate this work is done, the fewer mistakes made and less waste created.

We integrated specific sensors and software with our robotic welding tools that can inspect the welding area while the robots are operating. This enables the robots to visually take in what is unfolding around them and quickly make adjustments as needed. And they can adjust on the fly — for example, if something happens in the welding environment, the robots can change their movements and settings. This allows them to ensure that every weld is completed properly and efficiently, yielding improved outcomes.

To work faster, one of the greatest benefits of a automatic welding robot application is that it speeds up production. Our robots do very well repeating the same task over and over again and could work thousands of times faster than a human being can. More products are created in a shorter amount of time, which is critical for fulfilling customer needs.

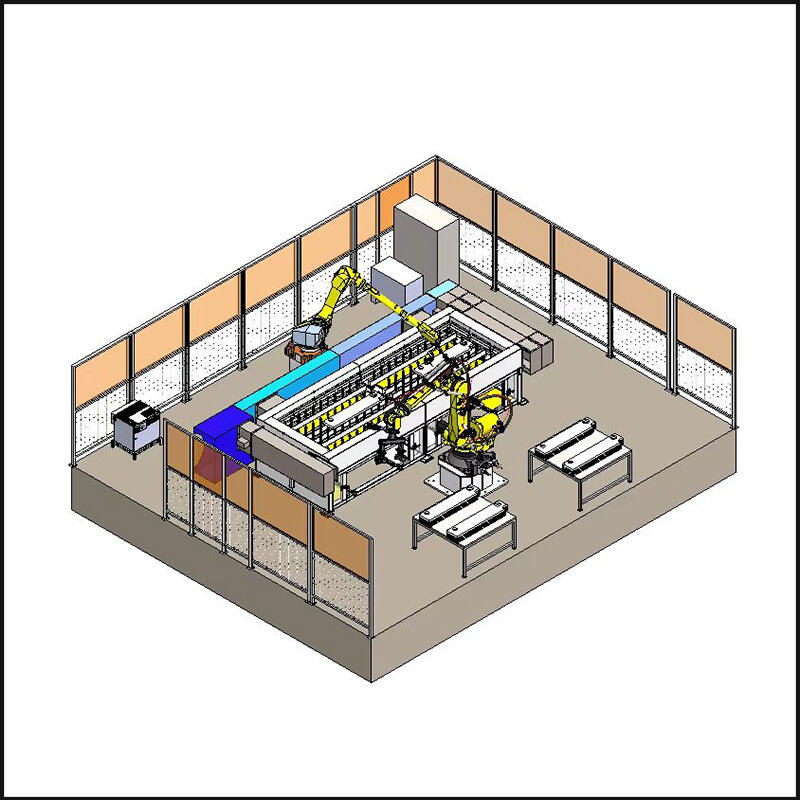

Welding is a crucial activity in any factory setting, regardless of industry, and safety is always a top priority. Welding is a dangerous job, but MINYUE robot laser welding machine are safe. They have safety barriers that keep workers protected from the machines, as well as emergency buttons that can take them out of operation instantly if something goes wrong.

Moreover, you can focus on the consistency and the correctness of the welds as well because of the robotic arm welding machine tools keep the processes safe. Our robots are able to make stronger and more durable welds by limiting human error and ensuring consistent welding conditions. That’s absolutely critical for ensuring the quality of the end product, and these welds meet, and in fact exceed, industry standards.

They are capable of being programmed to imitate numerous procedures, including spot welding and other types of seam welding. This agility is critical because it enables manufacturers to rapidly respond to shifting production requirements. If factories can switch the robots on and off and and what they’re doing, they can send their customers the product of high quality, on time and in full, every time.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.