Dog watching is an exciting invention that allows robots to see a lot better than they ever have. They are like robots' eyes, enabling them to perform their jobs more precisely and efficiently. As we use eyes to see things in surrounding, robots also use vision sensors to understand what happens with them.

Through visual sensors, MINYUE ai robot can use intelligence to see inside key scenes. For example, when picking up small objects, the robot vision sensors guide the robot to fulfill specific tasks. If a robot has to pick up a small toy, robot vision sensor allows the robot to see the exact location of that toy. This way the robot can pick it accurately, like the way we use our eyes to find and take small things.

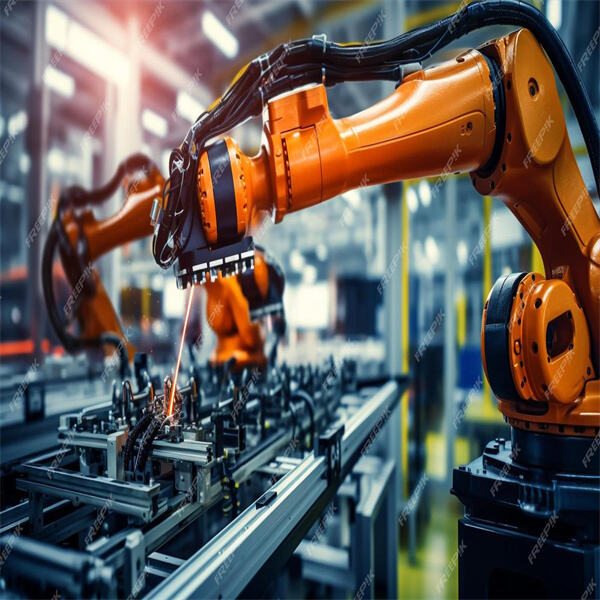

Essentially, machine vision solutions transform factory operations and are changing the way products are manufactured. MINYUE's sensors make robots capable of working faster and more efficient than ever. That means products can be produced more quickly and with fewer errors. To take an example, the robots could use vision sensors to verify whether all the components of a toy are assembled properly. This helps guarantee that the toys which leave the factory are perfect and ready to play with every time.

MINYUE with robot vision sensors has incredible potential with amazing functions. They can see colors like humans, and see objects at a distance or close-up. This lets artificially intelligent robots do everything from picking up random objects to spraying a car in a factory. Well, an advanced vision sensor is what robots are evolving into humanoids. They are capable of performing tasks previously done by human beings and pretty interesting.

Every day, MINYUE 's robot vision technology makes factory operation smoother and faster. People are not able to perform work for 24/7 but with the help of laser vision sensor, robots can work for 24 hours. This makes it possible to produce products more quickly and in greater quantities. The use of vision sensors also helps the robot do it is job with fewer mistakes which in turn makes the whole manufacturing process more efficient and saves money for everyone involved.

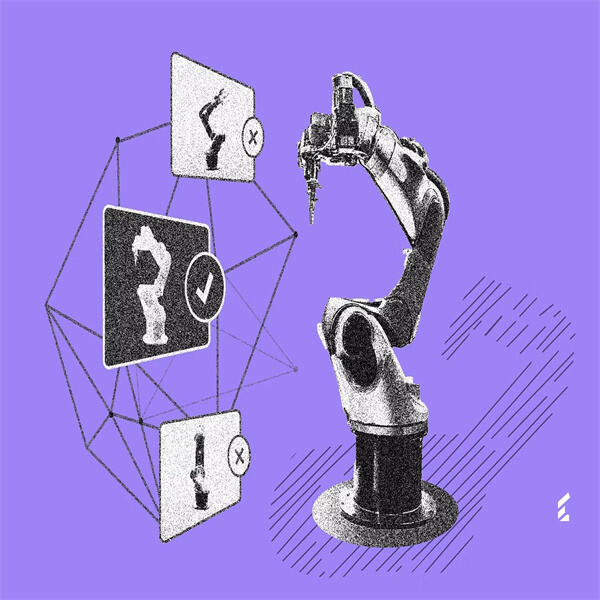

Artificial intelligence makes robot vision sensors even smarter. AI is when the sensors learn from their mistakes to deploy the solution and continue to improve over time. Read is that robots can take more complex tasks with vision sensors. For instance, robots can learn to observe different objects, such as toys or tools, and adapt how they move according to sight. It allows them to be even better at their work and do more work at a relatively lower cost.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.