Before we explore moving into the exciting world of automated and robotic welding sensors, let’s look at what these what those two words mean. Automated means that it moves by itself, but because no one has to manage each part of it is job. This means it can perform it is tasks without constant assistance from a human. Limited Robots are specialized machines for performing specific tasks on their own, like welding -- Of joining pieces of metal together. Sensors are critical elements of robots that serve as their eyes and ears. They help robots see and feel what’s happening around them and perform their jobs correctly and safely.

These MINYUE automated welding robot sensors can have many amazing benefits for the welding industry. To begin with, these sensors can operate far more quickly and make more judgments than human beings can. That means you can do so in much less time, and much less mistakes. Instead, they are also able to save themselves time and money while improving the quality of their products, if they use the sensors. This not only is good for the company but also results in better products for customers.

Well, MINYUE robot laser welding machine essentially make sure that the welding is done correctly. They possess specialized skills that enable them to identify defects that human vision is not able to recognize, like micro-cracks or uneven surface in the metal being welded. Robotic welding sensors ensure that the end product is strong, safe, and durable by catching the problems early in the process. Collectors of pieces made by welders will admire the enhanced longevity and performance, which are vital components for safety and quality.

Now, think about being in a huge factory with many machines all doing their own things to before producing different products. In this environment, automated welding equipment could be the conductors that bring it all together. These sensors work like a conductor directing a symphony, making sure each musician plays their part in harmony with the others -- Helping different parts of the production process communicate with one another. This all works smoothly together, allowing for a production line efficient and combined — everything runs like clockwork. With these sensors, the whole process can be more streamlined and structured, resulting in improved results.

No matter what the industry, safety is always the first priority; but when you are welding, the potential for everything turning hot and heavy is ever at your fingertips. Which is why MINYUE hides no secrets behind it is advanced automatic welding robot sensor technology which is designed to protect workers. They are capable of preventing accidents before occurrence bystanders. For example, they can warn individuals when something goes awry, such as excessive heat or pressure in a location. This warning allows workers to take action and right the situation before someone gets hurt. Organizations can develop a safer working environment for everyone involved by employing these new-age sensors.

Automation and robotics are the superheroes in the world of manufacturing. They simplify, speed up, and optimize perform work. These are powerful tools — and with automated welding sensors, companies can harness these powerful tools to make products that are high quality and built to last. These technologies help workers shift their attention to other imperative responsibilities as robots and sensors tackle the more monotonous or hazardous tasks.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

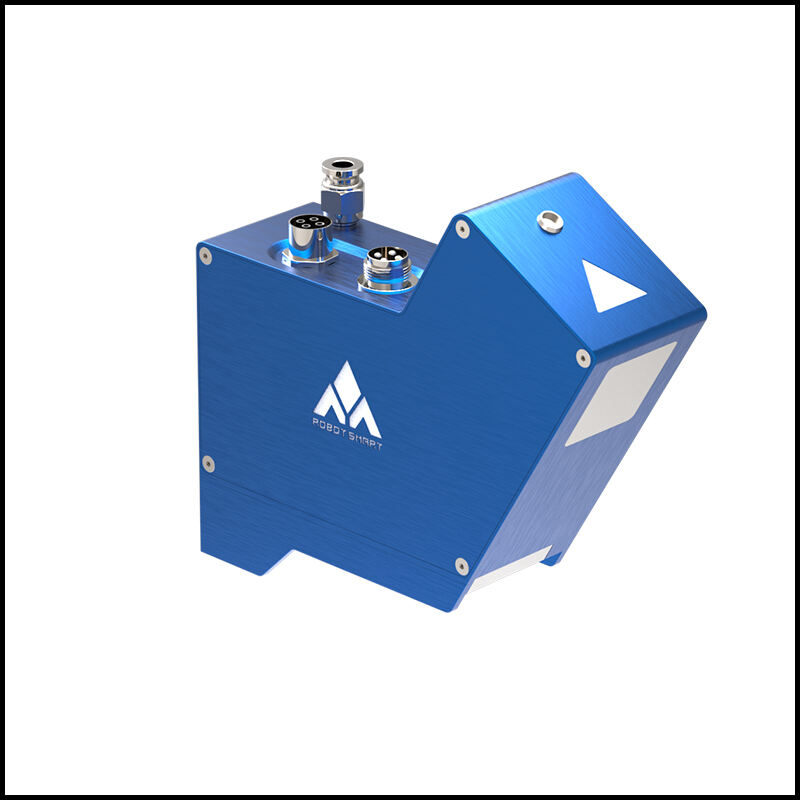

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.