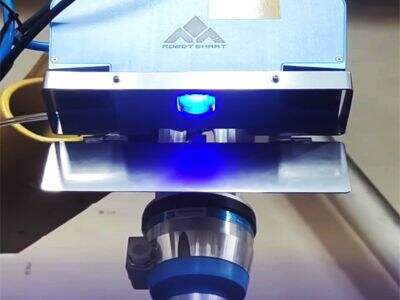

Ang pagwawelding ay isang termino na ginagamit kapag ang dalawang metal ay pinagsama gamit ang init. Ito ay isang mahalagang bahagi ng maraming industriya tulad ng bakal para sa paggawa ng metal chassis, aluminum para sa fuselages ng eroplano at mga tangke at oil tanker. Ang isang malaking bahagi ng proseso ng pagwawelding ay ang pagtiyak na ang weld ay maayos na ginawa at walang depekto sa loob ng iisang pass. Narito ang adaptive laser seam tracking sensor .

Bakit mahalaga ang adaptive seam tracking sa pagwawelding:

Ito ay teknolohiya na tumutulong sa mga manggagawa sa pagpuputol na matiyak nilang nasa tamang lugar ang kanilang pagpuputol, ang adaptive seam tracking. Mayroitong espesyal na sensor na nakikilala ang mga gilid ng metal na pinuputol nang magkasama. Ito ay mahalaga dahil kung hindi nasa tamang lugar ang sentro ng putol, ito ay nagdudulot lamang ng paghina sa metal at magkakaroon ka ng bagong problema sa artikulasyon ng bahagi. Ibig sabihin, sa tulong ng adaptive seam tracking, maaari mong tiyakin na matatag ang mga putol at walang tsansa na masira kapag ginamit sa pagkakabit ng mga istruktura ng malalaking barko o bangka.

Pagkamit ng maaasahang kalidad ng pagpuputol sa pamamagitan ng paggamit ng teknolohiyang adaptive seam tracking

Sa anumang paraan, ang pagpuputol ay tungkol sa pagkakapare-pareho. Ang isang hindi pare-parehong pagputol ay lilikha ng mga mahihinang bahagi na maaaring magdulot ng bitak sa metal. Pinananatili ang Pagkakapare-pareho: Ang adaptive seam tracker tampok na nagsisiguro na isinasagawa ang pagputol sa iisang lugar tuwing muli. Nagreresulta ito sa isang de-kalidad na pagputol na matibay at malakas.

Mga Adaptive Seam Tracking system upang mapataas ang katumpakan ng pagpuputol:

Mahalaga ang kawastuhan sa pagmamapa. Maaaring agad itong lumihis patungo sa kaliwa dahil lamang sa pinakamaliit na bagay. Pinapangunahan nila ang mampamapa kung saan dapat ilagay nang maayos sa buong proseso ng pagmamapa. Mas mababa ang posibilidad ng pagkakamali, gayundin ang mga mapang mas tiyak at tumpak. Pinahuhusay nito ang kawastuhan at nagbibigay-daan sa mga mampamapa na lumikha ng matibay, maaasahang mga mapa na sumusunod sa mga pamantayan ng industriya.

Malinaw na paningin sa linya ng pagmamapa para sa tumpak na resulta ng pagmamapa:

Ang kakayahang makita ang proseso ng pagmamapa ay isang katangian na nagbibigay-daan upang makita ang proseso ng pagmamapa. Upang mapabuti ang pagkakakita sa linya ng pagmamapa, maaari mong gamitin ang adaptive seam tracking upang matiyak na magagawa mo ang mahusay na pagmamapa sa unang pagkakataon. Adaptive seam tracking : gumagamit ng mga espesyalisadong camera at sensor na magpapakita ng malinaw na view sa lugar ng pagmamapa. Tumutulong ito sa kanila na magawa ang kinakailangang pagbabago para sa perpektong at tumpak na pagmamapa. Kapag nakikita ng mga mampamapa kung ano ang kanilang ginagawa, ang resulta ay mas mahusay na gawi sa pagmamapa at huling-huli ay mataas na kalidad ng pagmamapa.

Ang Rebolusyon ng Adaptive Seam Tracking

Kung ang tradisyonal na pagsubaybay sa tahi ang paraan kung paano gumagawa ng mga de-kalidad na tahi ang karamihan sa mga manggagawa sa pagwewelding, ang adaptibong pagsubaybay sa tahi ay may potensyal na maging makabuluhan. Ang adaptibong pagsubaybay sa tahi ay ang pinakabagong teknolohiya sa pagwewelding at ito ay pumapalit sa paraan ng paggawa ng mga welder sa isang proseso na mas katulad ng ating ginagawa kumpara sa ginagawa ng ating mga robot. Pinapayagan ng teknolohiyang ito ang mga welder na mag-welding nang mas mabilis at lumikha ng mas mahusay na tahi sa mas maikling panahon. Dahil dito, ang mga kumpanya tulad ng MINYUE ay nakatitipid ng pera at mga yaman habang patuloy na nakakamit ang mataas na pamantayan ng kalidad.

Talaan ng mga Nilalaman

- Bakit mahalaga ang adaptive seam tracking sa pagwawelding:

- Pagkamit ng maaasahang kalidad ng pagpuputol sa pamamagitan ng paggamit ng teknolohiyang adaptive seam tracking

- Mga Adaptive Seam Tracking system upang mapataas ang katumpakan ng pagpuputol:

- Malinaw na paningin sa linya ng pagmamapa para sa tumpak na resulta ng pagmamapa:

- Ang Rebolusyon ng Adaptive Seam Tracking

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK