Svarenje ima veliku važnost u nekoliko poslova, kao što su u proizvodnji opreme i građevinarstvu. To je način za spajanje dva metala uz pomoć topline. Tradično svarenje, na primer, može biti i vremenski troškast i izazovno da se obavi tačno. Ovo je mesto gde dolazi u igru napredna tehnologija praćenja reža.

Tehnologija praćenja šava Tehnologija praćenja šava je tehnologija koja pomaga svarenicima da prate put koji treba sleđiti prilikom spajanja dva kovana dela. Otkriva šav i pozicionira svarku duž njega koristeći senzore. To osigurava da je svarka odgovarajuće postavljena i sigurna.

MINYUE Zbog ovoga, razumeju potrebu za efikasnošću u svarenju, pa su stvorili jedinstvene alate koji pomažu u tome.

Poboljšanje preciznosti i brzine u procesima svarenja

Napredna tehnologija praćenja šava (npr. sistemi za vid svarka) omogućavaju povećanu tačnost i brzinu u svarenju. U tradicionalnom Inteligentno varivo , svarenik zavisi uglavnom od svoje vještine da pomakne svarku duž šava. Taj proces može biti dug i podložan greškama.

MINYUE koristi tehnologiju praćenja šava kako bi poboljšao preciznost svarenja. Senzori mogu da otkriju kada vatra nije na tačnom tragu i da je odmah prilagode. To se prevodi u bolje svare i manje greške.

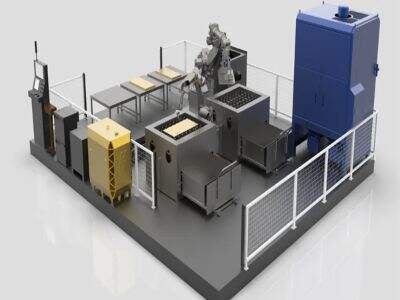

Tehnologija praćenja šava takođe ubrzava zavarivački robot proces. Senzori automatski vode vartu, omogućavajući radnicima za svarenje da rade brže. To znači da mogu da svaru više komada u kraćem vremenu, štedeći novac i vreme.

Praćenje šava: Automatizacija detekcije za usavršavanje svarenja

U svarenju; efikasnost je ključni faktor. Utiče na koliko se rada obavi i koliko to košta. Koristeći MINYUE-ovu tehnologiju praćenja šava, još uvijek možemo da učinimo operacije svarenja efikasnijim pružanjem veće brzine i smanjenjem vremena koje traje svarenje.

Svezanje postaje lakše sa ugrađenim praćilac šova, jer ne postoji potreba za ručnim prilagođavanjima. Svezivači više ne moraju da se brinu o praćenju šova, jer tehnologija to radi umesto njih. To oslobađa svezivače da se fokusiraju na druge poslove, poboljšavajući sve što se dešava.

Takođe, ova tehnologija pomaže u smanjenju otpada u заваривање procesu. Manje grešaka i otpadnog metala nastaje osiguravajući da je svaki sav napravljen na pravi način od početka. To smanjuje troškove za kompanije koje koriste tehnologiju MINYUE.

Kako automatski sistemi za praćenje šova doprinosе kvalitetnoj kontroli

Kontrola kvaliteta znači mnogo u svezivanju. Loše svezivanje može uzrokovati probleme i stvoriti opasnosti. Svaki sav mora biti čvrst i odgovarati odgovarajućem standardu.

Obradjene delove takođe smanjuju vreme popravke i otpad, jer se mogu proizvoditi sa izuzetno uskim tolerancijama, što poboljšava kontrolu kvaliteta. Senzori mogu da pronađu defektna mesta u svaru i obaveštaju svarača da prilagodi. Ovo osigurava da su svi jaci i odgovaraju zahtevima.

Koriste se i automatski sistemi za praćenje ševa kako bi se osigurala istovetna kvaliteta svarenja. Ta tehnologija osigurava da svi svarovi bivaju izvršeni konzistentno svaki put, automatski vodajući pochod. To rezultira jačim, konzistentnijim svarovima.

Dva · Korišćenje pračilaca ševa u operaciji svarenja za povećanu produktivnost i ekonomičnost

Maksimizacija produktivnosti i ekonomičnosti ključ je za uspeh operacija svarenja. MINYUE tehnologija za praćenje ševa pomaže da se poveća produktivnost i smanje troškovi, omogućavajući da se svarenje vrši brže i sa manjim resursima.

Praćači spojeva pomažu u povećanju produktivnosti povećavanjem brzine i preciznosti svarenja. Svarenici mogu da izvrše više svarenja u kraćem vremenu, šta povećava ukupni radni izlaz. To može rezultirati značajnim uštedama.

Takođe, praćači spojeva smanjuju i troškove proizvodnje. Plus, minimizovanjem otpada i osiguravajući da je svako svarenje tačno od prve, tvrtke mogu smanjiti troškove materijala i rada. Kao rezultat, operacije svarenja postaju još efikasnije, čime se tvrtke koje rade sa MINYUE tehnologijom koriste većom dobitnosti.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK