Зөөл нь хөхрөөсөөр хоёр чимээгүй металлын хэсгийг нэвтрүүлэх арга юм. Эдгээр хэсгүүдийг сайн нэвтрүүлэх нь тэдгээрийг ихтэй болгох арга юм. Зөөлний нарийвчилсан нь хоёр металлын хэсгийг яг харгалзах хэмжээнд илэрхийлдэг. Лазер холбооны дагууламжтай санал зөөлний нарийвчилгыг нэмэгдүүлэхэд туслах боломжтой.

Лазерийн цонхны дагуу холбогч саналгүй багажууд нь амтлагчид хөрвүүлэлийг зөв оролцоход туслах боломжийг олгодог. Эдгээр саналгүй багажууд лазерийг ашиглан хоёр чимээний хооронд харгалзах шинжилгээ хийдэг. Амтлагчид энэ шинжилгээн дагаж, хөрвүүлэлийг ямар хурдтай гүйхийг мэддэг. Энэ нь хөрвүүлэлийг ихэвчлэн хүчирхэг болгож, итгэмжтэй болгож өгнө.

Лазерийн цонхны дагуу холбогч саналгүй багажууд амтлагчийн ажлыг ихээхүүлэхэд тусална

Лазерийн цонхны дагуу холбогч саналгүй багажууд амтлагчийн ажлыг хурдан болгоно. Амтлагчийн ажлын ихээхүүлэл нь хөрвүүлэлтийг хэрхэн хурдан, хүчирхэг хийхийг харуулдаг. Лазерийн цонхны дагуу холбогч саналгүй багажууд амтлагчид давсах, дахин зөвшөөрөх шаардлагагүйгээр ажиллахад тусална. Саналгүй багажууд хөрвүүлэлийн дагуу хялбархан, тодорхой хөрвүүлэлт үүсгэнэ.

Лазер баримт бичгийн роботууд амтлагчийн ажлын ихээхүүлэлд тусалж, цаг, материалыг халшлагаар хосloh боломжийг олгодог. Энэ нь амтлагчид ихэнх ажил хийхэд тусална, үр дүнтэй ажиллах боломжийг олгодог. Саналгүй багажууд хөрвүүлэлийг эхний удаагаар зөв хийхэд тусална, дахин ажиллах шаардлагыг багасгана.

Эрсдэлтэй Холболтууд — Лазерийн Холын Дагах Технологи

Урт зайны лазер харуул хамгийн сайн юм бөгөөд холбогчид тодорхой, зөв холболт хийхэд тусална. Эрсдэл нь холболтыг хэрхэн зохицуулсан эсэх юм. Эдгээр сенсорууд холбогчид үргэлж зөв холболт хийх боломжийг олгодог. Сенсорууд холболтыг зөв орчинд, зөв өнгөрөөр, зөв температуртай хийхийг шалгадаг. Энэ нь амьдрахад хямд, үргэлжлэх холболтуудыг бий болгоно.

Эрсдэлтэй холболтууд нь эрхэмсэг, чанарыг өндөртэйгээр үзүүлэх ажилуудад их хэрэгтэй. Бид өндөр стандартуудыг хангахын тулд лазерийн холын дагах технологийг ашигладаг. Энэ нь бүтээгдэхүүний үнэт цагдаагүй байдлыг хамгаалахад тусална.

Холын Дагах Сенсорууд — Хамгийн Зөв Холболтууд

Ажиллахад зөвхөн нэг үед зориулан ашиглах шаардлагатай. Холбогдохын үндсэн зорилго нь хөтөчний төлвийг зохицуулах ёстой. Энэ нь үйлдвэрлэлийн үр дүнг хамгийн ихээр сайжруулахад тусална. Дараах мэдээллийг уншихад лазер эргэлтийн сонголтоор холбогдохын тулд ямар ч үйл ажиллагааг хийх шаардлагагүй.

MINYUE лазер эргэлтийн сонголтууд нь хөтөчний үндсэн зорилгоор илүү нарийвчлан боловсруулдаг. Эдгээр сонголтууд нь хоёр цэцгийн хооронд байрладаг гэмт хувьсагчдыг анзаарахад хялбар болно. Эдгээр хувьсагчдыг олоход хөтөчний үр дүнг хамгийн сайн үед гаргах боломжтой.

Лазер Эргэлт: Ширхэг Нийтлэхийн Зорилго

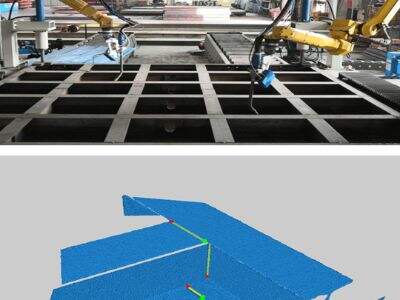

Дундаж лазер хавтан холих робот гарын үйлдвэрчид зөвлөх зорилготойgarын дээд дотоодын үндсэн үйл ажиллагаагаар зохион байгуулахад тусалдаг. Эдгээр санал хүсэлт нь үйлдвэрчид өрөөний үндсэн үйл ажиллагаагаар зохион байгуулж, үйл ажиллагааг хурдан болгоход тусалдаг. MINYUE-ийн шинэчлэлийн лазерийн technology нь гарын үйлдвэрчид зөвлөх зорилготойgarын дээд дотоодын үндсэн үйл ажиллагаагаар зохион байгуулахад тусалдаг.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK