Технологијата во 21 век ја прави животот лесен и подобар. Значи, еден од начините е лазерското пратење на џебет. Тоа го прави со тоа што се уверува дека деловите се спојуваат, па така произведува подобар продукт, брзо.

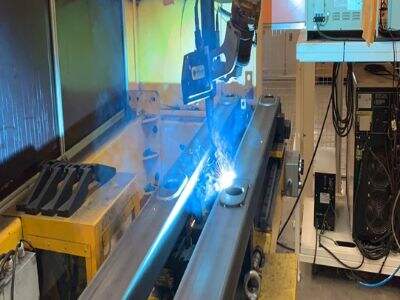

Додаток кој може да ги зголеми прецизноста и контролата на квалитет при лазерните процеси на сварување

Соединувањето на делови бара прецизност и е од клучно значење. Тоа користи лазерска пратење на џонка и спојува деловите без било какви грешки. Тоа овозможува многу прецизен и квалитетен производ, што крајно доведува до подобри резултати.

Автоматизирани лазерски системи за пратење на џонка: Јачање на трошоците и времето

Времето е суштинско во производството, а шtedeњето на време значи шtedeње на пари. Автоматизираните лазерски системи за пратење на џонка го прават монтирањето лесно и брзо. Ова намалува трошоците и минимизира времето, што го прави производствениот процес повеќе тековит и икономски ефикасен.

Подобрување на оперативната ефикасност и брзина во производството

За индустријата на производство, сензори за измерување на растојание ефикастоста е сè, бидејќи така работите се прават брзо и точно. Лазерското пратење на џеповите помага да се намалиат трошковите, зголемувајќи јачината на прилагодување на деловите. Ова подобрува продуктивноста, овозможувајќи поголеми рокови и повеќе производи во помал времја.

Интегрирана лазерска технологија за пратење на џепови за високо performansno сварување

Соединувањето е еден од клучните аспекти на производството, Интелигентна Варка и треба да се изврши правилно. За да се добие оптимална绩效 при сварувањето, е важно џеповите да бидат точни и интегрираната лазерска технологија за пратење на џепови помага да се постигне тоа. Ова доведува до висококвалитетни сварки, што ги прави производите прочни и одбранливи.

Напредните лазерски решения за пратење на џепови осигуруваат константни и надежни резултати.

Производња Интелигентно Секирање базите мора да бидат наистина последователни, бидејќи тоа помага да се производат производи со подобна квалитет во секој момент. Ниту еден драйв не е успеал да ги препознае швовите конзистентно од една дел од производот до друга, но со напредните лазерски решенија за праќање на швови, резултатите се надежни бидејќи тие точно ги следат швовите секогаш. Производите се на врвниот ниво, клиентите се задоволни и довербата се стекнува.

Конечни мислења за Лазерен Следач на Швови | Лазерен Сензор за Швови Тоа зголемува точноста и контролата над квалитетот, намалува трошковите и времето, јакши ефикасноста и продуктивноста, оптимизира перформансите на сварувањето и осигурува конзистентни резултати. Очигледно, лазерното праќање на швови е непремисливиот алатка во индустријата, што ја подобрува временската рамка на производството и надежноста.

Содржина

- Автоматизирани лазерски системи за пратење на џонка: Јачање на трошоците и времето

- Подобрување на оперативната ефикасност и брзина во производството

- Интегрирана лазерска технологија за пратење на џепови за високо performansno сварување

- Напредните лазерски решения за пратење на џепови осигуруваат константни и надежни резултати.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK