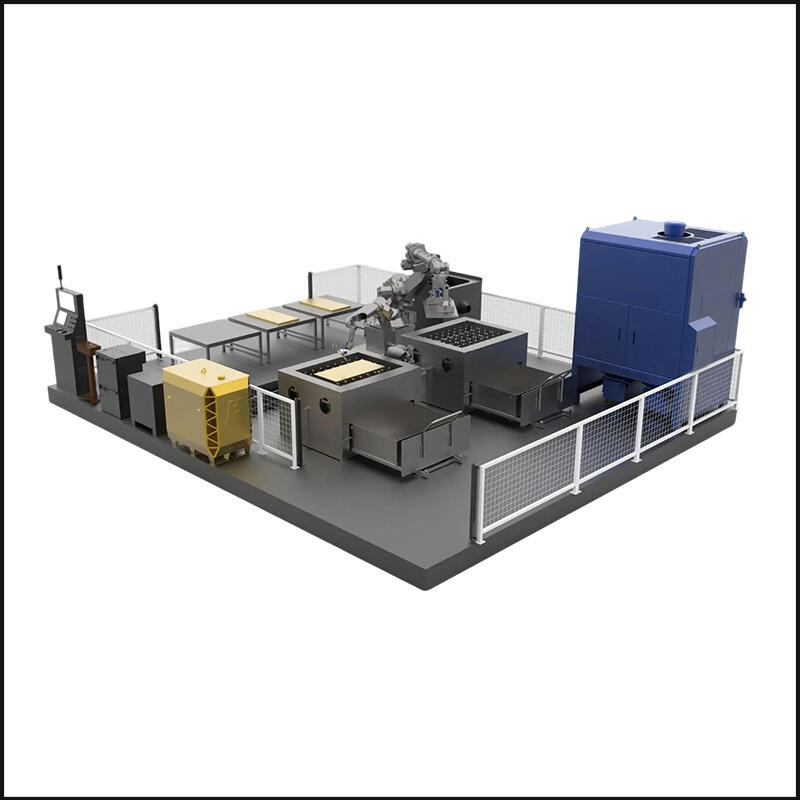

Մեքենայական տեսողության համակարգը սահմանվում է որպես ժամանակակից լցման գործընթացների վերահսկման համար նախատեսված հիմնարար տեխնոլոգիական բաղադրիչ, որն ապահովում է որակի երաշխիք, ավելի բարձր արտադրանքի թողունակություն և արտադրության ցածր ծախսեր: Այն տեխնոլոգիան, որն ուշադրություն է դարձնում արդյունաբերական ռոբոտներում ինտելեկտուալ կիրառմանը, նվիրված է առաջատար արտադրանքներին և ծառայություններին զուգահեռ մնալուն:

Լցման ընթացքում որակի վերահսկման վրա մեքենայական տեսողության ազդեցությունը

Ամենակարևոր ավելացված արժեքի առավելություններից մեկը ավտոմատացված 捍գող մաքինա հատուցման առաջարկը սեղմման գոտում որակի վերահսկումն է: SmartEye, SmartVision-ի մշակած տեխնոլոգիան կարող է երաշխավորել ճշգրիտ կարի հետևումը և թերությունների ստուգումը: Այս հնարավորությունները բարելավում են սեղմման ընդհանուր որակը՝ հնարավորություն տալով հսկել և վերլուծել, ինչպես նաև անհրաժեշտության դեպքում արագ կատարել կարգավորումներ՝ ապահովելու համապատասխան ստանդարտների կատարումը սեղմումների համար:

Մեքենայական տեսողության տեխնոլոգիայի օգտագործմամբ արդյունավետության և ճշգրտության բարելավում

Մեքենայական տեսողությունը ոչ միայն բարելավում է սեղմման որակը, այլ նաև թույլ է տալիս ավելի մեծ արդյունավետություն և ճշգրտություն սեղմման գործընթացում: Ավտոմատացնելով գործընթացներ, ինչպիսիք են կարի հետևումը, ստուգումը և չափման խնդիրները, տեսողական համակարգերը նվազեցնում են ձեռքով աշխատանքի կախվածությունը, ինչպես նաև նվազեցնում են սխալների ռիսկը՝ միաժամանակ ավելացնելով արտադրության արագությունը: Minyue Technology-ի RobotSmart օֆլայն ծրագիրը նույնպես ավելացնում է արդյունավետություն՝ պարզեցնելով ռոբոտի ծրագրավորումն ու սիմուլյացիան, ինչը հանգեցնում է ավելի արագ կարգավորման ժամանակին և ավելի բարձր գործընթացային հուսալիության:

Տեսողական համակարգերով սեղմման գործընթացի աշխատանքային ժամանակի բարելավում

Կապման գործընթացի տեսողական համակարգերը դարձել են արտադրողականությունը բարելավելու համար կարևոր գործոն, որը նպաստում է արդյունավետ շահագործմանը և դադարների նվազեցմանը: 3d machine vision camera minyue Technology-ի տեխնոլոգիան կարող է հեշտությամբ ինտեգրվել ռոբոտի տարբեր մոդելների մեջ և ապահովել տարբեր տեսակի կապման համար հարմար տեղադրում: Տեղադրման ժամանակի կրճատումը և արտադրողականության բարելավումը թույլ են տալիս արտադրողներին ապագայում ավելացնել արտադրանքի թողարկման չափաքանակները՝ իջեցնելով ծախսերը և ավելի հզոր/վարպետացած աշխատողներ պատրաստել:

Օգտագործելով ամենահաջող մեքենայական տեսողության ֆունկցիոնալությունը

Տեխնոլոգիան բարելավում է կապման գործընթացի վերահսկողությունը՝ իրական ժամանակում վերլուծություն և տվյալների անալիտիկա կիրառելով: Այս robotic welding machine price թույլ են տալիս արտադրողներին հսկել և վերլուծել կարի գործընթացի կարևորագույն փոփոխականները, ինչպիսիք են ջերմաստիճանը, արագությունը և լարի արագությունը՝ ապահովելով ամենահամազոր որակը և արդյունավետությունը: Բարդ տեսողական համակարգերի օգտագործման շնորհիվ արտադրողները ավելի մեծ վերահսկողություն են ձեռք բերում իրենց կարման գործընթացների նկատմամբ և բարելավում են վերջնական արտադրանքի համազորությունն ու հուսալիությունը:

Բարելավեք կարի որակն ու համազորությունը՝ միջոցով առաջադեմ տեսողական տեխնոլոգիաների

Առաջադեմ տեսողական տեխնոլոգիաները, ինչպիսին է Minyue Technology-ի SmartEye-ի և SmartVision-ի լուծումները, կարևոր գործիք են բարձր որակի և համազոր կար ապահովելու համար: Ճշգրիտ կարի հետևումով, սխալների հայտնաբերմամբ և կարի ստուգումով այն ապահովում է, որ բոլոր կարերը համապատասխանում են նախապես որոշված որակական չափանիշներին: Սա անմիջապես հանգեցնում է թափոնների և վերամշակման նվազեցմանը, ավելի մեծ հաճախորդների բավարարվածության և ամբողջությամբ ավելի մրցունակ դարձնում է կարման արդյունաբերության մեջ աշխատող արտադրողներին:

Բովանդակության աղյուսակ

- Լցման ընթացքում որակի վերահսկման վրա մեքենայական տեսողության ազդեցությունը

- Մեքենայական տեսողության տեխնոլոգիայի օգտագործմամբ արդյունավետության և ճշգրտության բարելավում

- Տեսողական համակարգերով սեղմման գործընթացի աշխատանքային ժամանակի բարելավում

- Օգտագործելով ամենահաջող մեքենայական տեսողության ֆունկցիոնալությունը

- Բարելավեք կարի որակն ու համազորությունը՝ միջոցով առաջադեմ տեսողական տեխնոլոգիաների

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK