ظهور ردیاب هوشمند قرن بیست و یکم برای دقت جوشکاری رباتیک

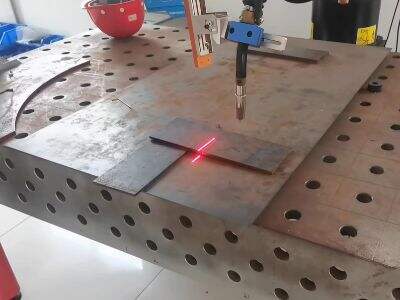

ردیاب درز هوشمند، چشم فوقالعاده هوشمند ربات جوشکار است. این دستگاه میتواند درز بین قطعات فلزی را ردیابی کند و اطمینان حاصل کند که ربات با دقت کامل روی آن حرکت میکند. این موضوع بسیار مهم است، زیرا حتی کوچکترین اشتباه در جوشکاری میتواند باعث ضعیف شدن اتصال و کاهش استحکام آن شود. همچنین ردیابهای درز هوشمند قادرند نتایج جوشکاری پویا و قابل پیشبینی را برای سیستمهای جوشکاری رباتیک ارائه دهند. این امر منجر به ساختارهای فلزی قویتر و یکنواختتری میشود که میتوانند وزن و فشار زیادی را تحمل کنند.

تاثیر یک ردیاب درز هوشمند بر کیفیت جوش رباتیک

رباتهای جوشکار با کمک ردیابهای درز هوشمند قادر به کار سریعتر و کارآمدتر هستند ردیابهای درز . با نظارت دقیق بر روی درز، این دستگاهها قادر به جوشکاری در زمان کوتاهتر و با دقت بیشتری هستند. این موضوع هم زمان را صرفهجویی میکند و هم خطر انجام مجدد جوشکاری را کاهش میدهد — کاری که میتواند هزینه و زمان قابل توجهی به پروژه اضافه کند. رباتهای جوشکاری با استفاده از ردیابهای هوشمند درز، قادر به کار با عملکردی باکیفیت و تولید مداوم جوشهای باکیفیت هستند.

مزایای ردیابهای هوشمند در ثبات کیفیت جوش

ایجاد جوشهای قوی برای هر سازه فلزی ضروری است، زیرا کیفیت جوش تعیینکننده دوام سازه متصلشده است. ردیابهای درز اجزای ضروری برای جوشکاری موفقیتآمیز رباتیک هستند و ما از آنها در سراسر جهان استفاده میکنیم. با هدایت ربات به ردیابی درز، این دستگاهها به تولید جوشهای قوی و یکنواخت کمک میکنند که در استانداردهای لازم قرار دارند. این موضوع همچنین بدان معناست که محصولات فلزی تولیدشده با ربات هوشمند درزیاب ردیابهای درز قابل اعتمادتر و ایمنتر برای استفاده هستند.

چگونه ردیابهای هوشمند درز، کاربردهای جوشکاری رباتیک را ساده میکنند

هوشمند ردیابهای درز جرثقیلهای رباتیک را ساده کنید و میزان مشارکت دستی مورد نیاز را به حداقل برسانید. پس از پیکربندی، این دستگاههای هوشمند میتوانند بهصورت مستقل کار کنند و ربات را هدایت کنند تا جوشهای دقیق را بدون نیاز به نظارت نزدیک ایجاد کنند. به این ترتیب، اپراتورهای انسانی میتوانند زمان خود را صرف مسائل دیگر کنند و در نتیجه فرآیند جوشکاری بهینهتر و کارآمدتر شود. ردیاب درز هوشمند: افزایش کارایی و ارزش. با بهبود عملکرد فرآیند، ردیاب درز هوشمند باعث صرفهجویی در زمان و هزینه شرکتها خواهد شد و در عین حال کیفیت جوش را تضمین میکند.

ردیابهای درز هوشمند چگونه جوشهای رباتیک را بهبود میدهند

در صنایعی که سازههای فلزی در معرض بارهای سنگین یا در محیطهای خشن استفاده میشوند، کیفیت اتصالات جوش اهمیت زیادی دارد. دستگاههای ردیاب درز (Seam Trackers) برای اینکه رباتها همواره جوش کامل ایجاد کنند، بسیار ضروری هستند. این دستگاهها به منظور دنبال کردن خودکار درز و کنترل پارامترهای جوش در صورت نیاز طراحی شدهاند تا هرگونه عیب یا ناهمواری در جوش را از بین ببرند. نتیجه نهایی، جوشهایی قوی و مطمئن است که در آن استانداردهای کیفیت و ایمنی رعایت شده است.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK