Cutting operations are essential to a number of industries, such as manufacturing, construction and automotive. It is the process of breaking and cutting of the materials into a particular design or shape. It is of importance to have accurate cutting technologies in place to get the right quality and productivity of materials produced. At Minyue, we acknowledge the significance of scientific cutting techniques and strive to develop superior cutting processes' influence on product quality and productivity.

The Physics of the Precision Cut

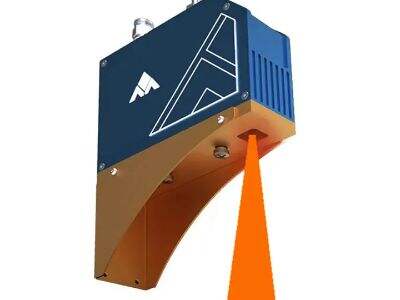

Such a high level of precision requires the use of technology and machinery to get precise uniform results. Processes such as WRP-220 Laser seam tracking sensor, water jet cutting, plasma cutting are employed in industry. These include cutting with high-energy sources in order to achieve precise and fast material removal. Adjusting the cutting speed, power intensity and nozzle distance to suit your needs is all that's required for optimal results, without waste.

Effects of cutting operations on the quality of products

The cutting process in the manufacture determines the quality of a product. Exact cutting process prevents from overcutting of the material needed for final production. The result is consistent uniform sized products, with similar shape and quality, which meets industry standards. " Manufacturing Benefits With this investment in advanced cutting technology, manufacturers can experience the benefits of a superior quality product and establish themselves competitively in the marketplace.

Modern cutting technology for improved efficiency

The cutting technology today is completely changed and industries are now using it to perform the best cutting. Cutting and efficiency Automation, robotics and AI are vital to driving cutting operations efficiently. Cutting parameters can be best optimised, waste reduced and output increased with state of the art software systems. Through the use of state-of –the-art cutting technology, fabricators are able to make their operations more efficient, cost-effective and productive.

Unlock the Advantages of Rational Cutting Techniques

A scientific cutting process provides a variety of benefits to the manufacturers through accuracy, less waste and safety. Incorporation of these practices can result in a superior degree of quality control and hence, better products and customer satisfaction. Furthermore, scientific cutting permits manufacturers to adhere to strict industry standards and regulations so that defects, recalls or problems do not occur. In general, use of scientific techniques of pruning could result in increased productivity and profitability of the enterprises.

Increase Production by Cutting Smartly

Strategic cut plans are critical to efficiency and out-put. When planning and optimizing cutting processes manufacturers can avoid cut errors, minimize material waste, save time. Strategic Cutting also requires the use of a cutting machine with proper care and calibration to deliver uniform results. Through applying strategic cutting approaches, suppliers can realize high level of productivity to meet customer needs and remain competitive.

cutting are important for many other fields including manufacturing, civil constructions and automotive. Through applying precision cutting skills, and using contemporary cutting technology, and scientific methods of cutting, it is possible to optimize quality as well efficiency and productivity outcomes. At Minyue, we strive to deliver the most advanced and intelligent solutions and technologies for customers’ manufacturing needs with engineering excellence that is second to none. By being precise, efficient, and quality focused we strive to be the partner you can count on for all your cutting wants.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK